Deformation stability monitoring system for the whole process of slope and dam construction period and initial impoundment period

A monitoring system and whole-process technology, applied in infrastructure engineering, on-site foundation soil survey, construction, etc., can solve problems such as spatial dispersion, time discontinuity, and inability to monitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

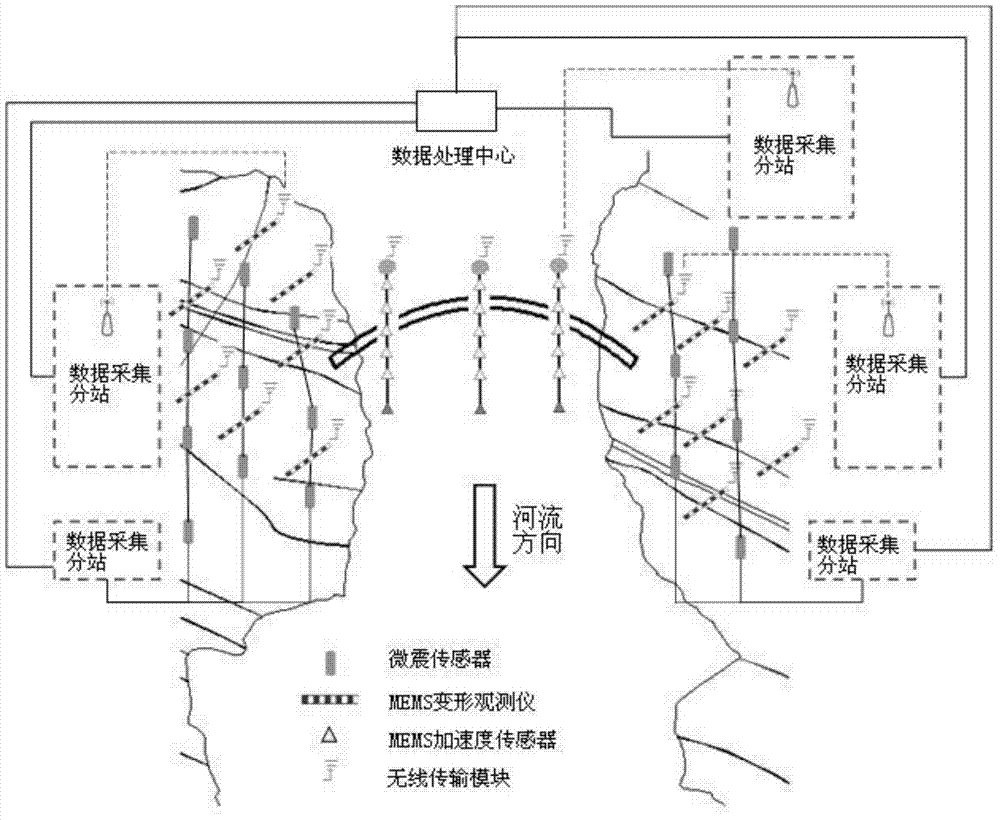

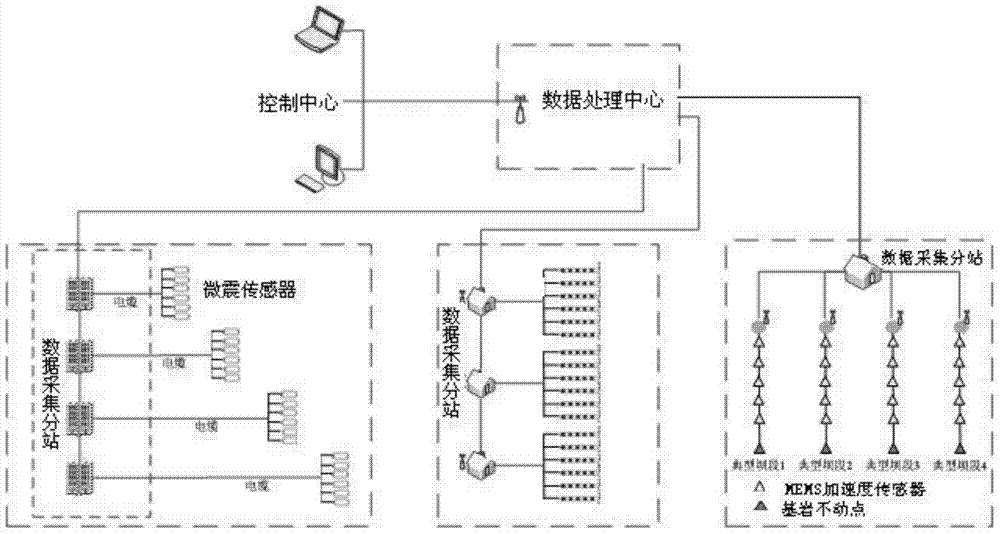

[0032] Such as figure 1 , 2 As shown, the deformation stability monitoring system for the whole process of the slope and dam construction period and the initial water storage period disclosed by the present invention includes a microseismic monitoring subsystem, a distributed MEMS deformation observer, and a data acquisition and processing subsystem;

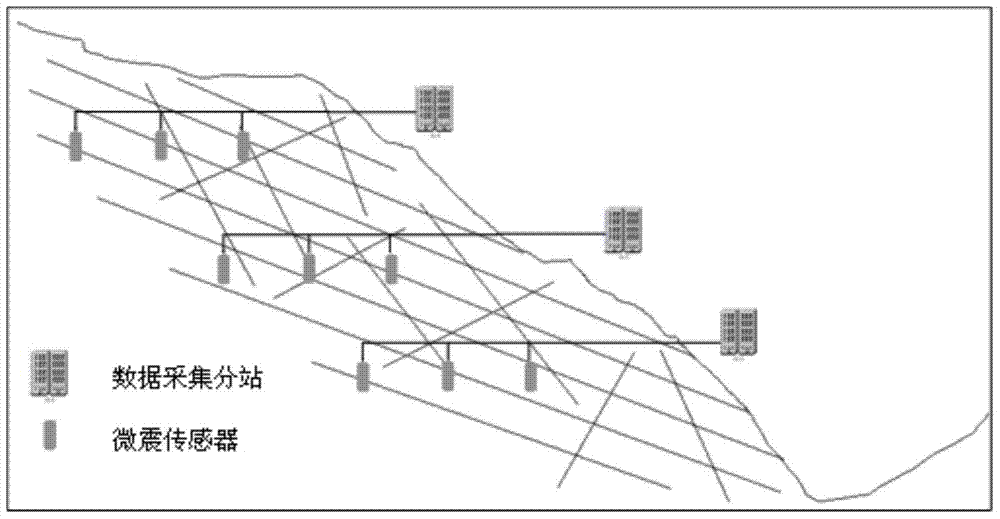

[0033] The microseismic monitoring subsystem includes a number of microseismic sensors arranged on the slope, which are used to sense various signals that trigger rock microfractures generated during the rock mass blasting excavation, concrete pouring and water storage of the slope. Among them, the layout position of the microseismic sensor is determined according to the previous geological survey. It is generally arranged on the slope where faults and joints and fissures are relatively develop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com