Method for controlling soil water erosion of in-situ leaching abandoned mine land of ion-type rare earth mine

An ionic rare earth ore, in-situ leaching technology, applied in the direction of sewage removal, water supply devices, waterway systems, etc., can solve problems such as adverse effects of sediment environment, loss of water-fixing and soil-preserving functions, unreasonable arrangement of hole network parameters, etc. To ensure the practicability and longevity of service life, avoid uneven settlement and damage, and meet the needs of plant irrigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

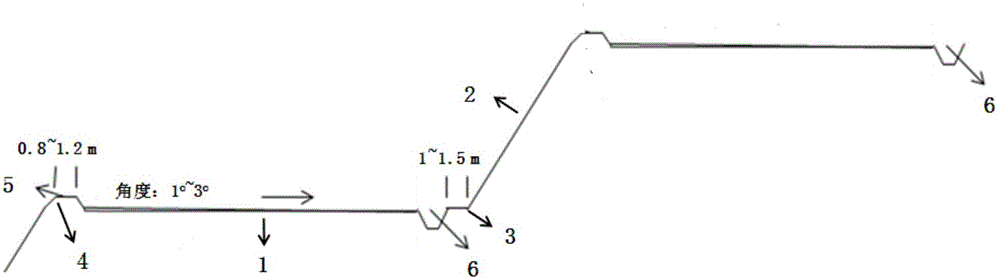

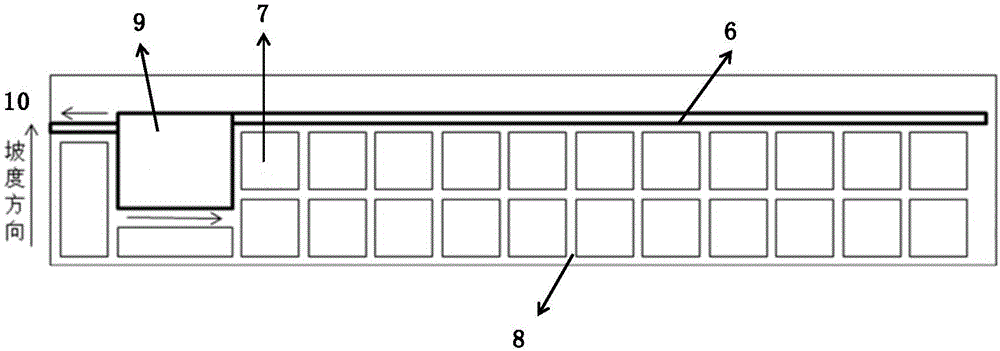

[0098] see figure 1 and figure 2 A schematic structural diagram of the system obtained by the soil hydraulic erosion control method of the in-situ leaching method of the ion-type rare earth ore mining trace is shown, and the soil hydraulic erosion control system of the mining trace of the ion-type rare earth ore in-situ leaching method includes a gentle slope 1 .

[0099] This embodiment is mainly aimed at hydraulic erosion control measures for small terraced mining sites. Take a terraced mining site with a width of about 9m and a length of 75m as an example. The soil hydraulic erosion control method of the ion-type rare earth ore in-situ leaching method mining trace in this embodiment can be implemented through the following steps:

[0100] (1) Utilize the large-scale loader to organize the plane ground of the mining site to form a gentle slope 1, and the direction of the gentle slope 1 is inclined from the edge 4 of the plane ground opposite to the foot of the slope 3 to ...

Embodiment 2

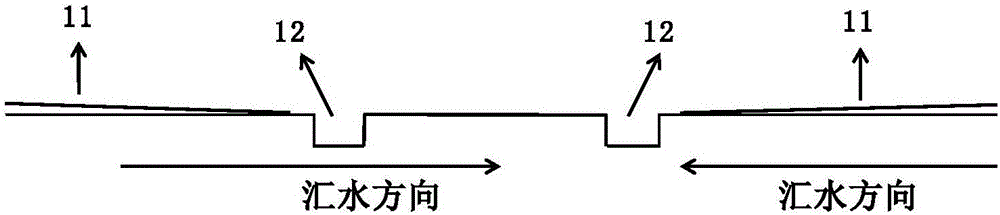

[0113] see image 3 and Figure 4 A schematic structural diagram of the system obtained by the soil hydraulic erosion control method of the in-situ leaching method of the ion-type rare earth ore mining trace is shown, and the soil hydraulic erosion control system of the mining trace of the ion-type rare earth ore in-situ leaching method includes a gentle slope 11 , diversion channel 12, field block 13, diversion channel 14, reservoir 15, overflow channel 16 and grit chamber 17. This embodiment is mainly aimed at the hydraulic erosion control measures taken on a large flat land, taking a flat land with a width of about 50.8m and a length of 105m as an example. The soil hydraulic erosion control method of the ion-type rare earth ore in-situ leaching method mining trace in this embodiment can be implemented through the following steps:

[0114] (1) Utilize the large-scale loader to organize the plane ground of the mining site to form a gentle slope 11, and the gentle slope 11 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com