All-prefabricated assembling type environmentally friendly retaining wall and construction method

A prefabricated assembly and retaining wall technology, applied in construction, underwater structures, infrastructure engineering, etc., can solve the problems of long construction period and inconvenient construction, and achieve the advantages of shortening construction period, significant economic benefits, and improving long-term greening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

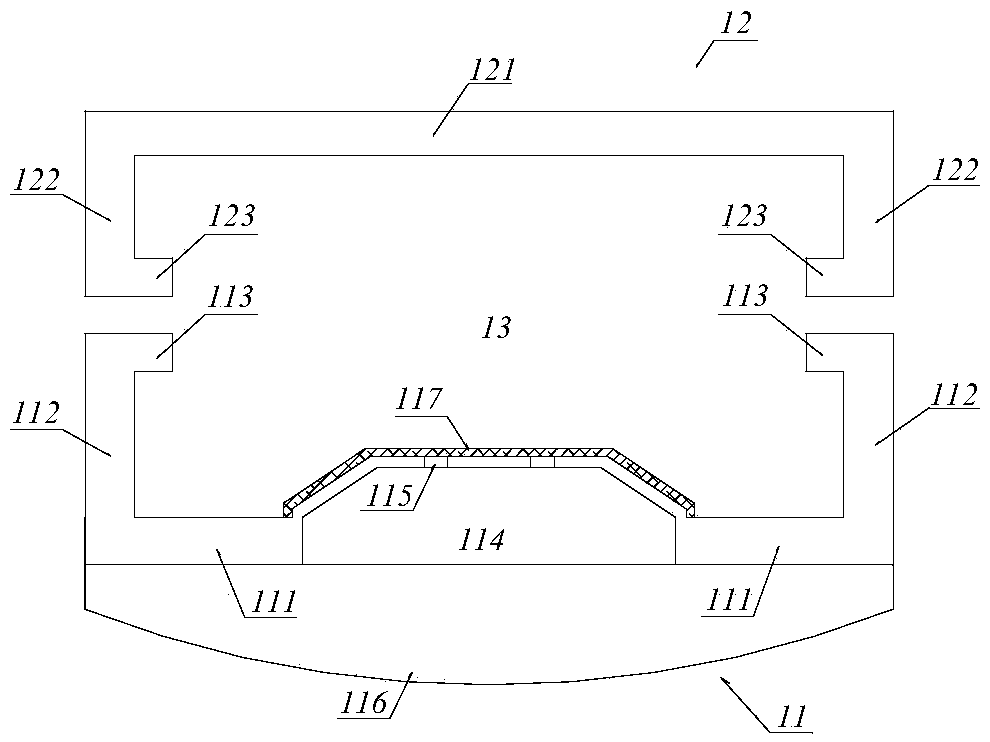

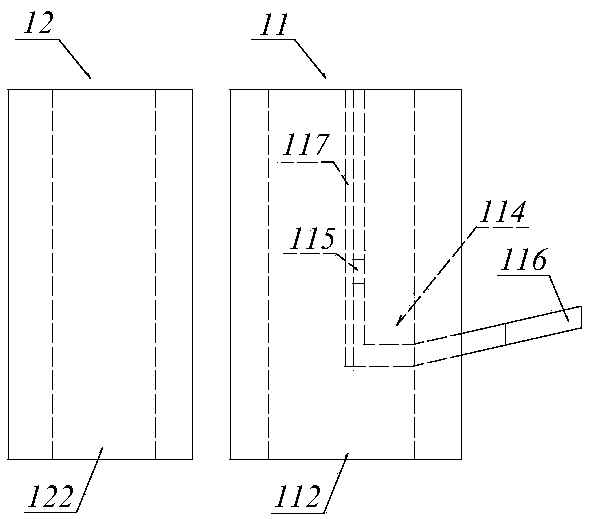

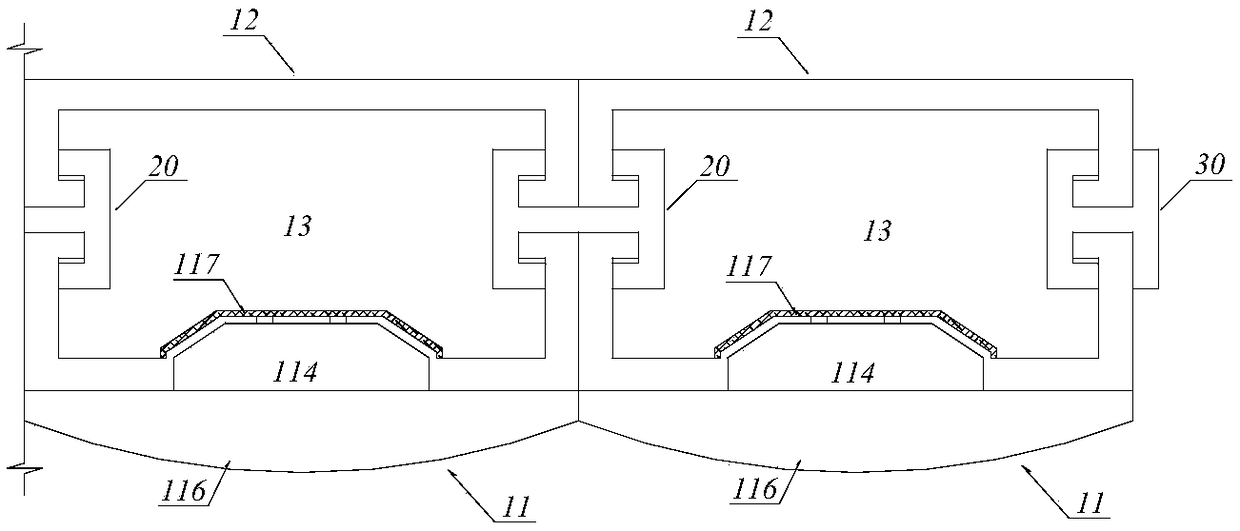

[0039] refer to image 3 , Figure 8 and Figure 12, the fully prefabricated assembled green retaining wall of the present invention, the retaining wall structure is formed by the horizontal and vertical assembly of prefabricated block units and is located on the structural foundation, and each prefabricated block has a structure protruding forward from the outer wall of the front plate. The planting board 116. The adjacent prefabricated block units assembled horizontally and vertically are connected and locked by snap-fit structures arranged on the side walls of both sides thereof, or are connected and locked by vertically arranged prefabricated connectors. The inner units of each prefabricated block have vertically connected internal cavities 13. After horizontal assembly, plain soil, sand pebbles or crushed stones are filled in layers in each in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com