Downhole Electric Heating Steam Generator

A steam generating device and the technology of the generating device, which are applied in the directions of steam generation, steam generation methods, lighting and heating equipment, etc., can solve the problems of limited fluid heating temperature, increased operating costs, easy clogging of heavy oil, etc. The effect of less air pollution and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

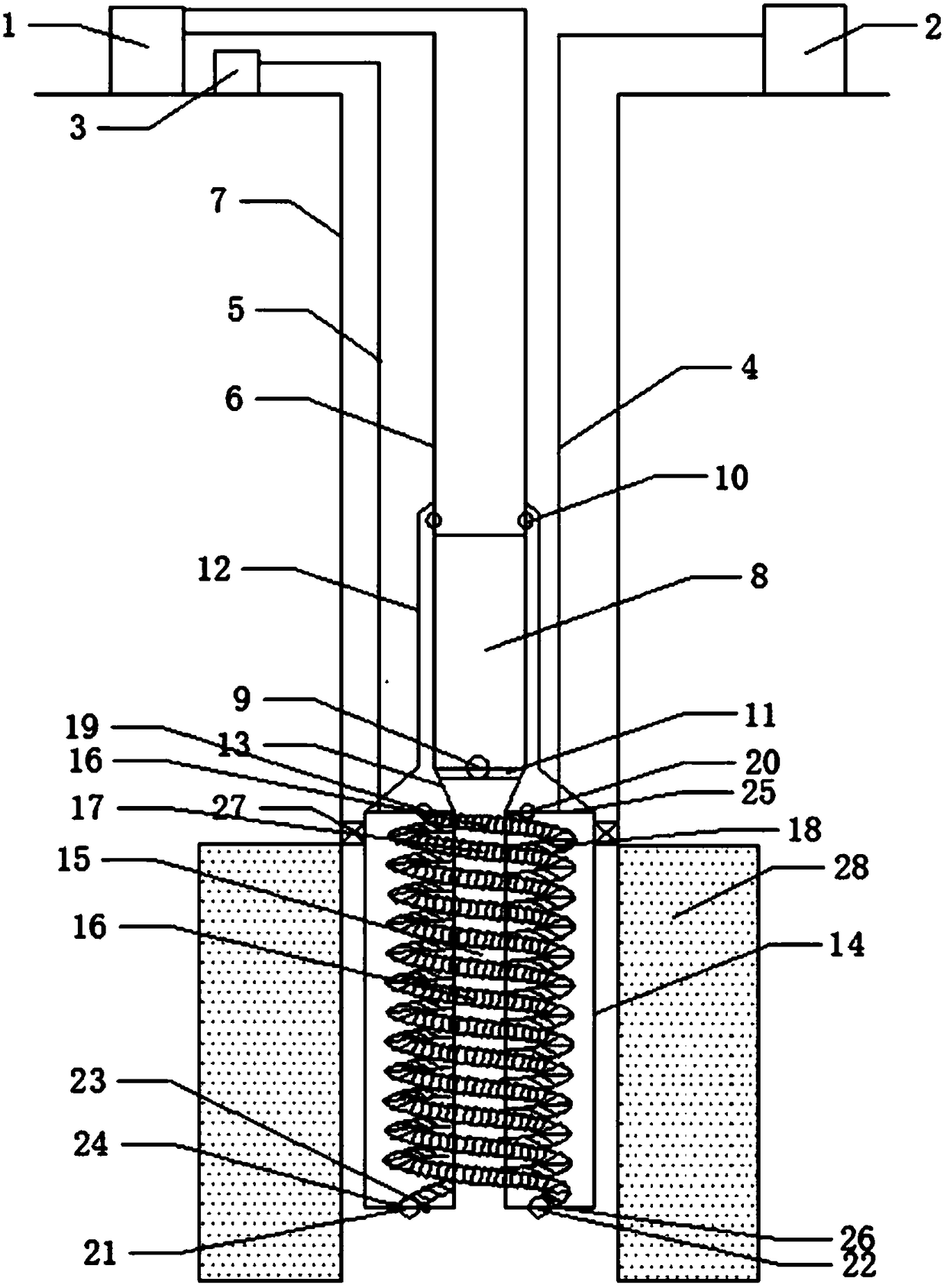

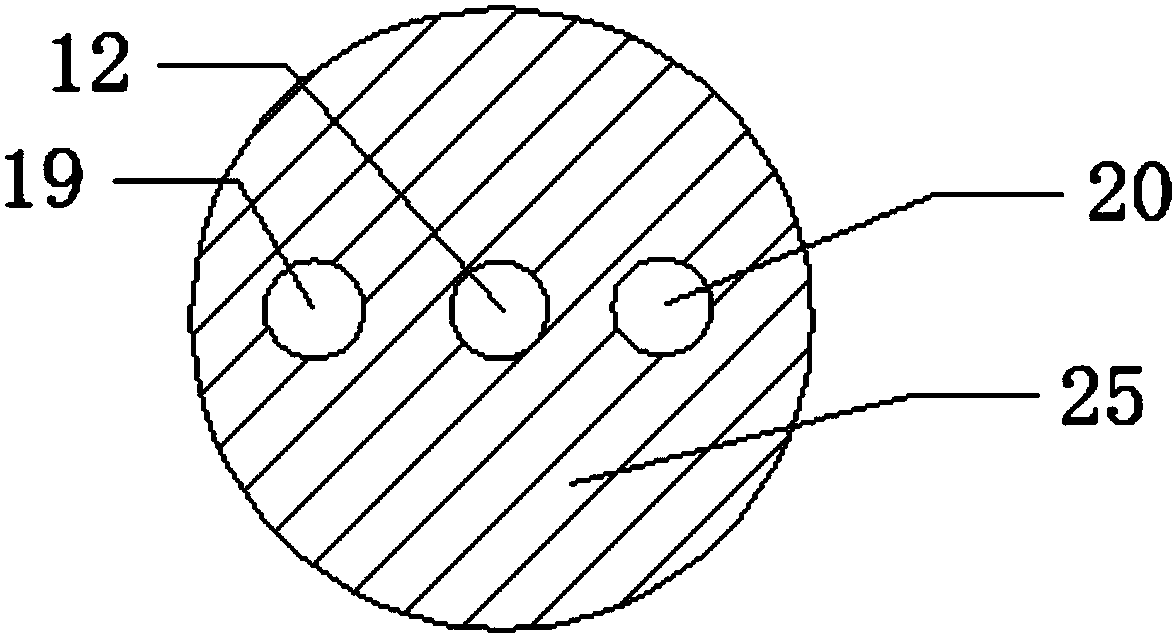

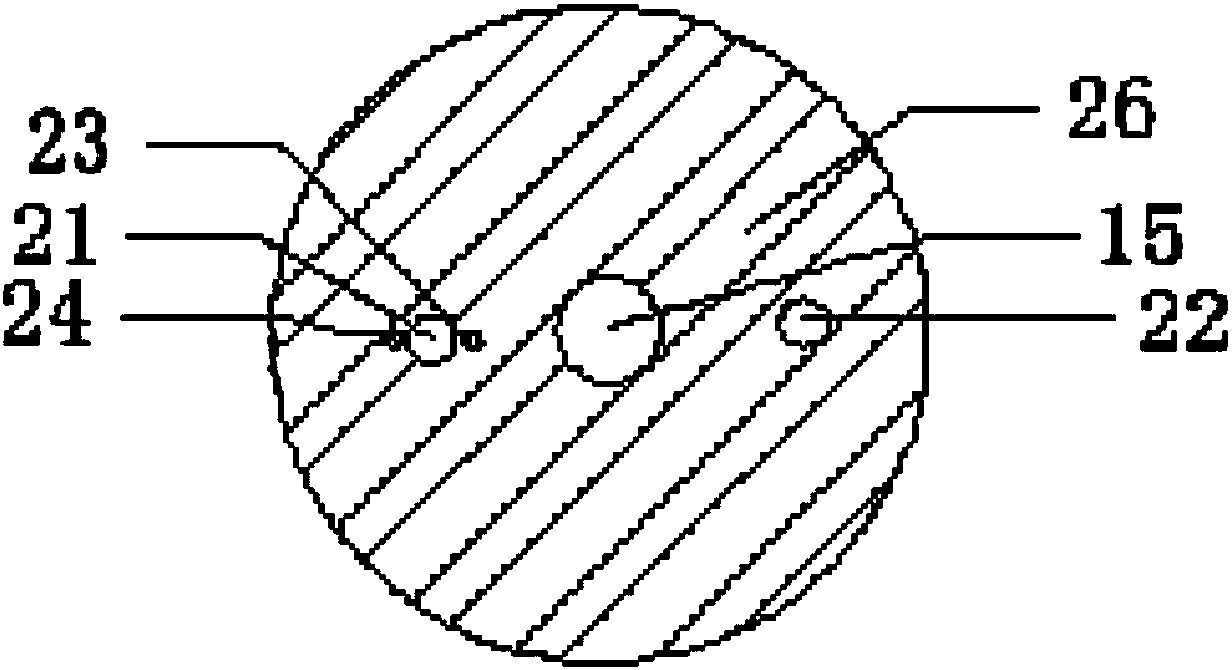

[0024] Please refer to figure 1 As shown, the present invention specifically provides a downhole electric heating steam generating device, the generating device includes: oil pipe 6, pump barrel 8, electric heating steam generator and thermal spiral tubes 16, 17; wherein the electric heating steam generator Including: a hollow tube 15, a cover 12, an upper cover plate 25 of the housing, a lower cover plate 26 of the housing and a housing 14; the generating device is connected with an oil pipe 6, a pump barrel 8 and a hollow tube 15 in sequence from top to bottom , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com