Glass pipeline and magnetic selector connecting system for flour processing

A connection system and magnetic separator technology, applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of inconvenient raw material transportation and observation, poor wear resistance, etc., to increase wear resistance and reduce system cost, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

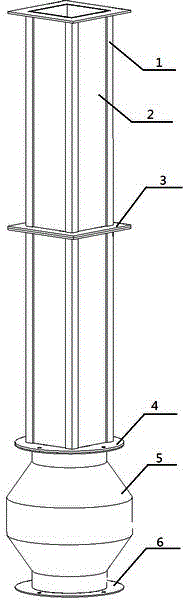

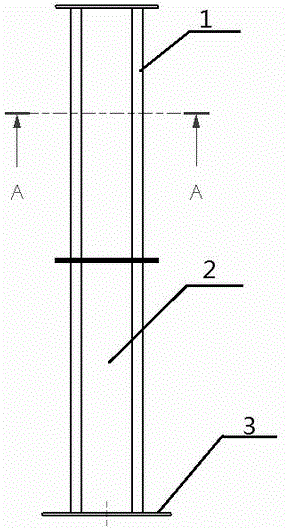

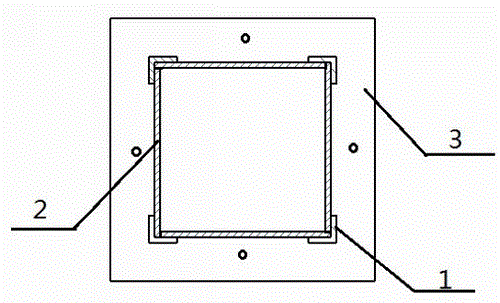

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention is positioned at the angle iron 1 on the edge, is positioned at the square iron frame 3 at the end and glass 2 to form a glass pipe, the angle iron 1 that adopts is the standard part that is convenient to buy, and four angle irons 1 encircle the quadrangle, adopt Four pieces of glass 2 are bonded to the angle iron 1 to form the wall of the glass pipe. The inner side of the square iron frame 3 at the end is welded on the angle iron 1. On the one hand, it is used to prevent the glass 2 from slipping out from the top; As a connecting flange for multiple pipes. The bottom outlet of glass pipe is connected with magnetic separator 5, and for convenience glass pipe is connected with magnetic separator 5, the circular flange plate-4 of the bottom of glass pipe is designed into the shape of outer circle inner square. The glass has strong wear resistance and visibility, and the pipeline uses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com