A square led downlight

A technology of LED downlights and LED light sources, applied in the field of lighting, can solve problems such as low light uniformity, affecting the comfort of downlights, dark lines and black holes, etc., to improve light uniformity, improve environmental adaptability, and reduce light loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

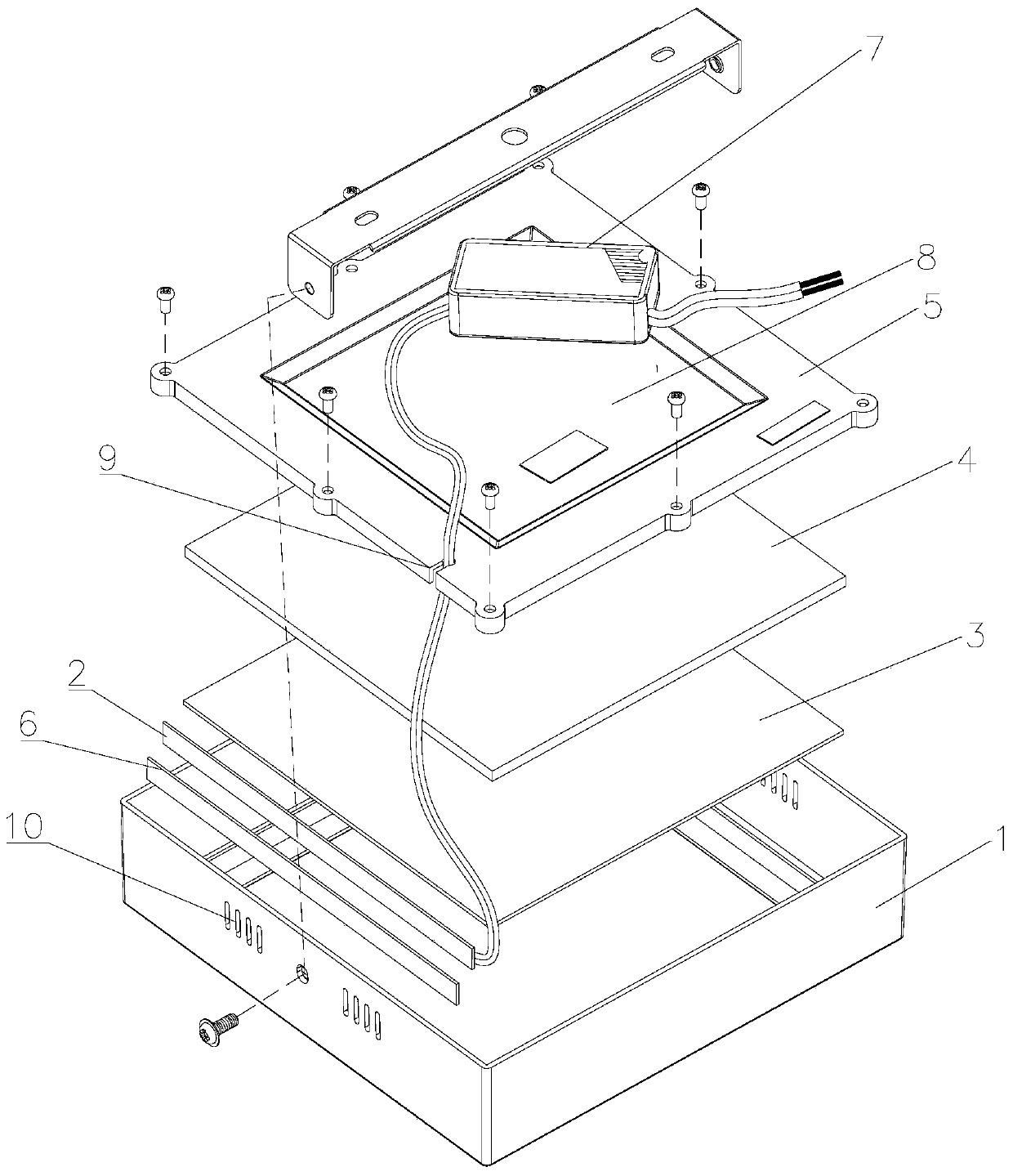

[0041] see figure 1 , which is an exploded view of the structure of the square LED downlight described in this embodiment.

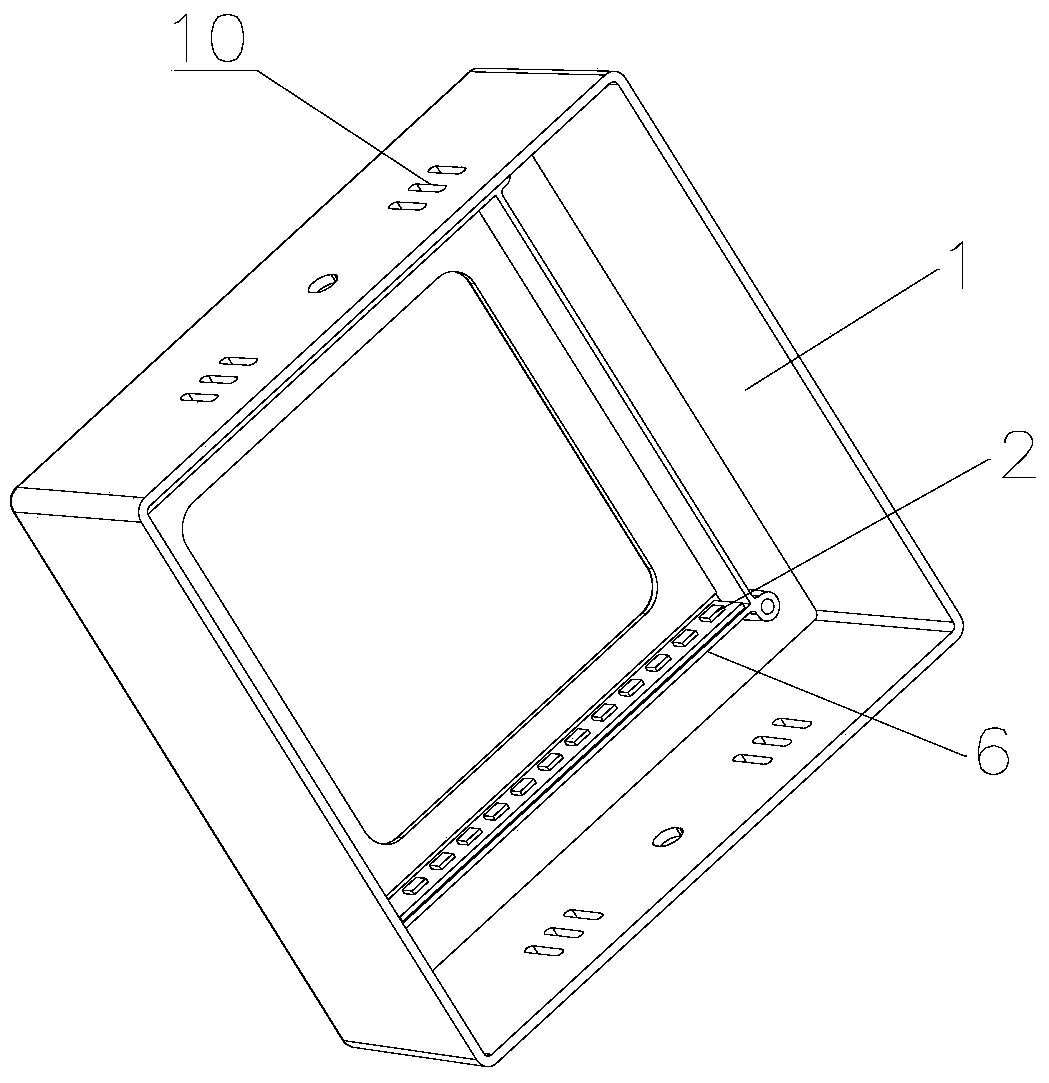

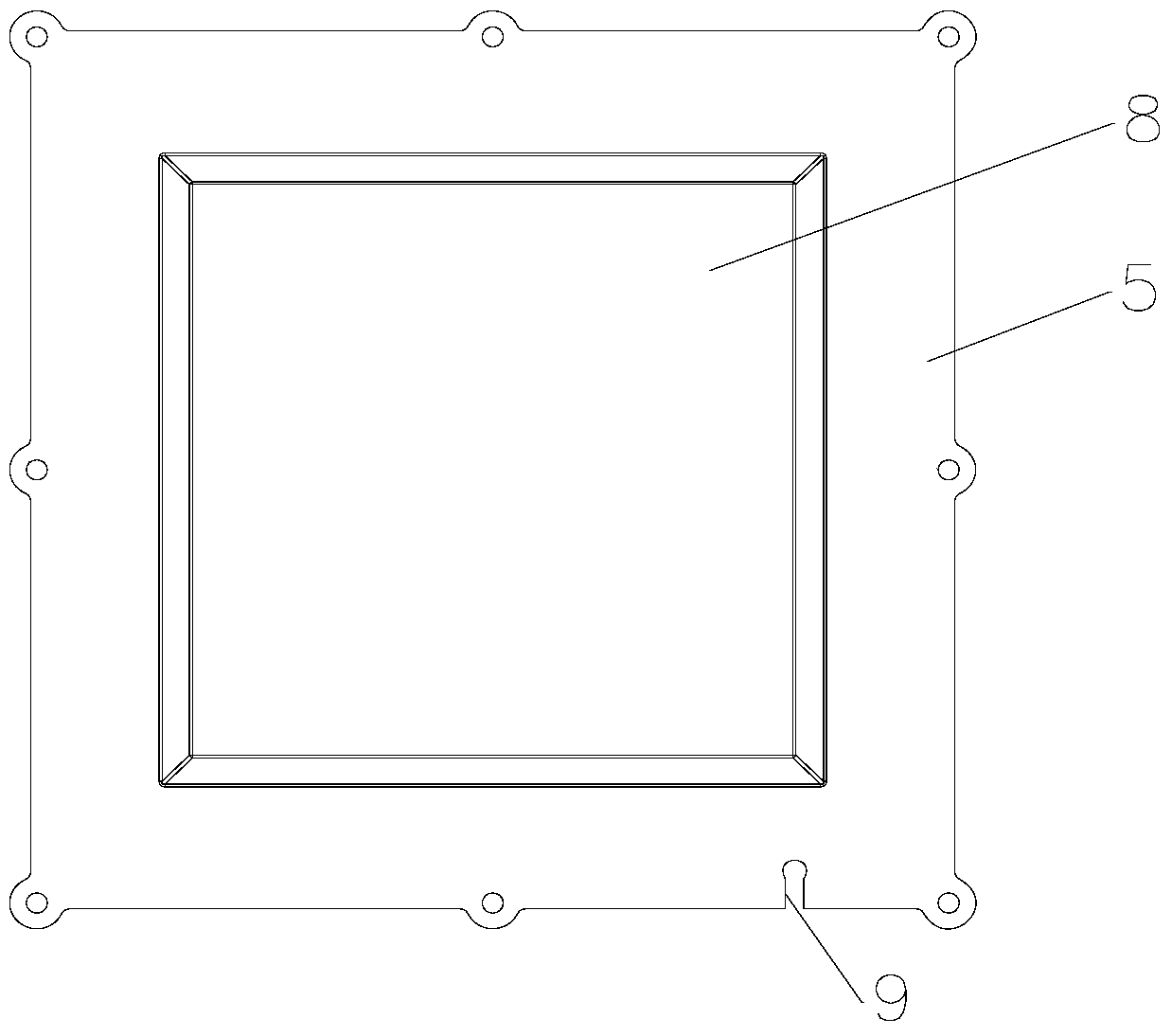

[0042] A square LED downlight comprises a lamp body 1, an LED light source assembly 2, a diffusion mask 3, a light guide element 4 and a back cover 5 for sealing the backlight surface of the lamp body. Among them, the diffusion mask 3 and the light guide element 4 are arranged in the lamp body 1, and are arranged in sequence from the outside to the inside; the LED light source assembly 2 is fixed on the side wall of the lamp body 1 and vertically arranged between the diffuser mask 3 and the light guide element 4 . The diffuser cover 3 is used to close the light emitting surface of the lamp body 1 , thereby forming a seal on the light emitting surface and the backlight surface of the lamp body 1 together with the back cover 5 , and sealing the LED light source assembly 2 and the light guide element 4 in the lamp body 1 . The cross-section of the lamp bo...

Embodiment 2

[0048] The light-guiding microlens on the back side of the light-guiding element in the above-mentioned embodiment 1 is a Spline spline curve convex lens designed and determined according to the principle of marginal rays in non-imaging optics and Snell's law of refraction, and its shape is mainly composed of the following The steps are calculated to determine:

[0049] a) Assuming that a single microlens substrate P is a rectangle with a side length of a×b, and the outgoing light obtains a W×L rectangular light plate on the target surface Q, the lens is divided into rectangles by N warp lines and M latitude jump lines respectively, In the same way, the light spot on the target surface is also divided into rectangles;

[0050] b) According to the theory of edge optics, when the values of N and M are large enough, the light intensity of each grid is uniform, and the light intensity of each grid can be obtained only by tracing the edge of the grid. Assuming that the incident ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com