An Experimental Device for Measuring Venturi Overflow

An experimental device, Venturi technology, is applied in measuring devices, testing/calibrating devices, detecting fluid flow by measuring differential pressure, etc. It can solve the problems of weakening vapor diffusion flow and decreasing condensation efficiency, and achieves novel design, easy operation, The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

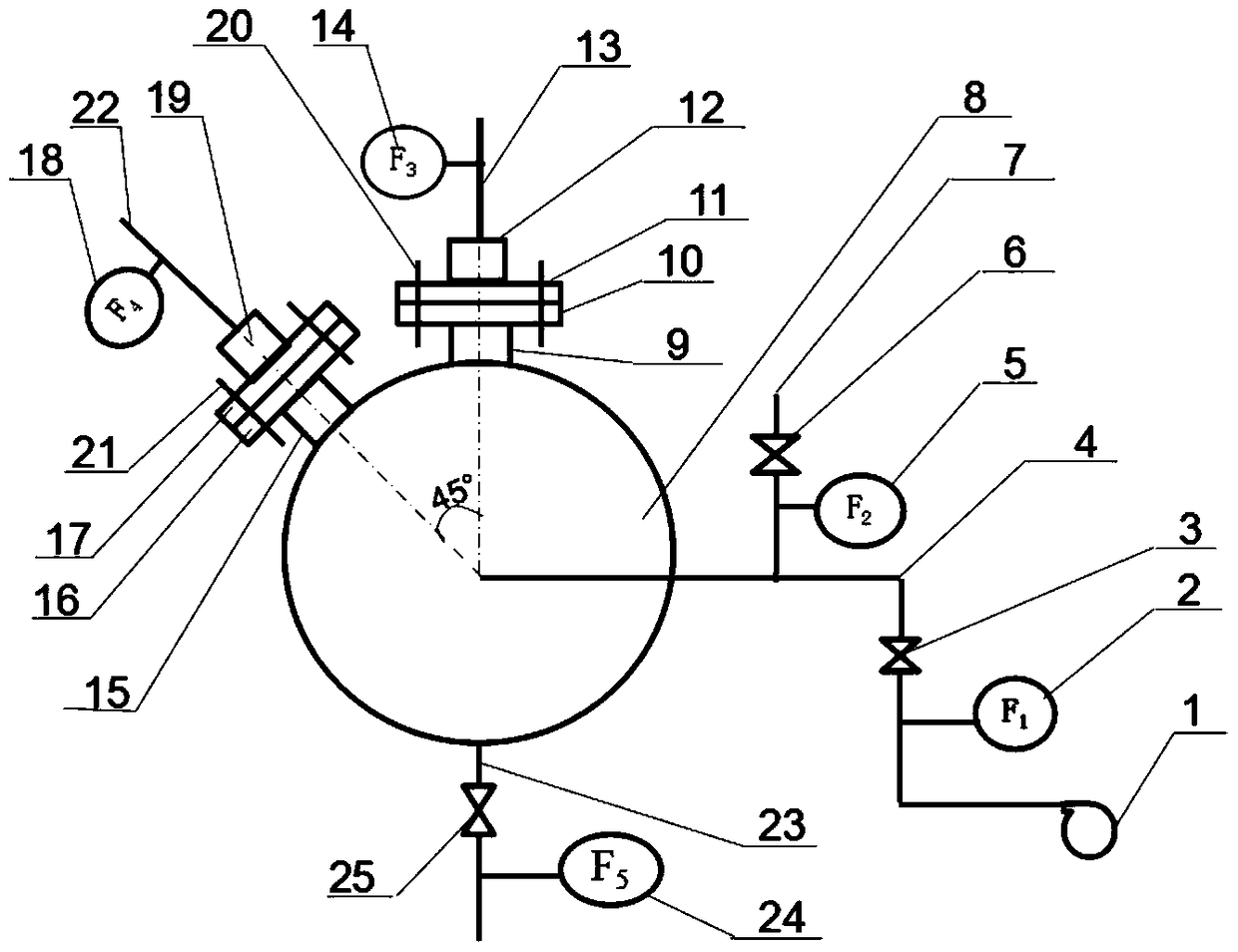

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

[0022] see figure 1 , the experimental device for measuring Venturi overflow of the present invention includes a main air pipe 8 and an air inlet pipe 4, a fan 1 is connected to the air inlet pipe 4, and a first flow meter 2, an air inlet valve 3 and a discharge pipe 4 are installed on the air inlet pipe 4. Trachea 7, second flow meter 5 and deflation valve 6 are installed on deflation pipe 7. The other end of the air intake pipe 4 is connected to one end of the main air pipe 8, and a Venturi bottom pipe I 9 is welded at the top center of the middle section of the main air pipe 8, on which the lower orifice plate I 10 and the upper orifice plate I 11 are respectively welded , Venturi top pipe I 12 is provided on the upper orifice plate I 11, and the lower orifice plate I 10 and the upper orifice plate I 11 are connected together with the bolt group I 20. Venturi bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com