Vibration curve normalized average life prediction method of equipment components

A vibration curve and average life technology, applied in the field of equipment life prediction, can solve problems such as inability to make accurate predictions, and inability to obtain estimates of how long it will continue to be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

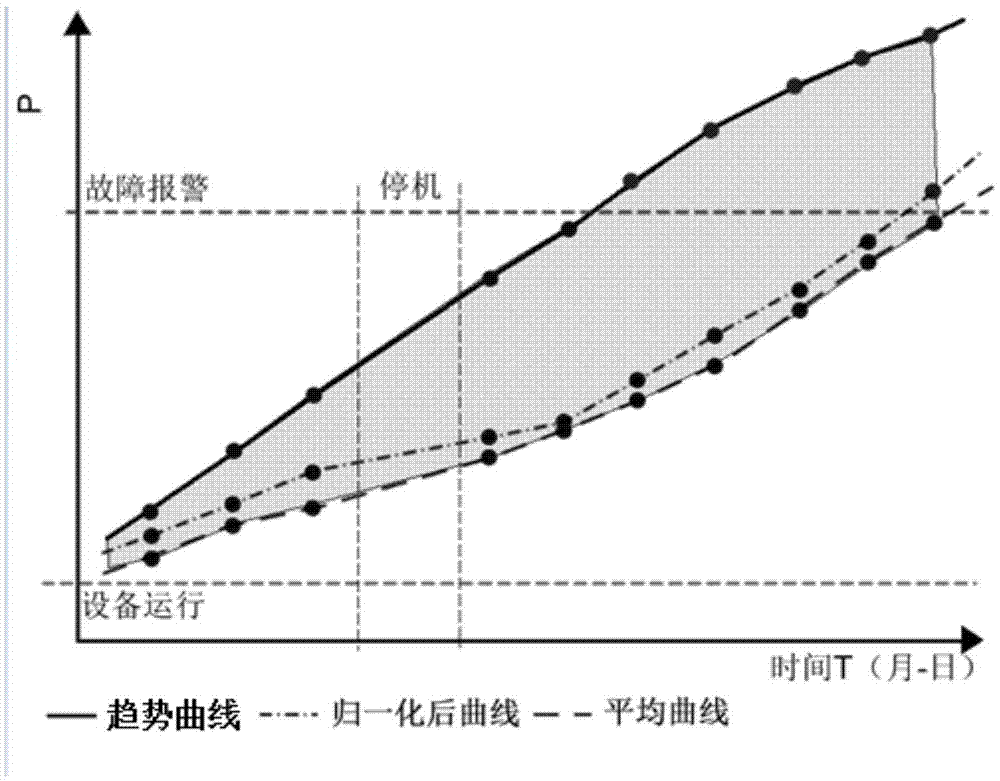

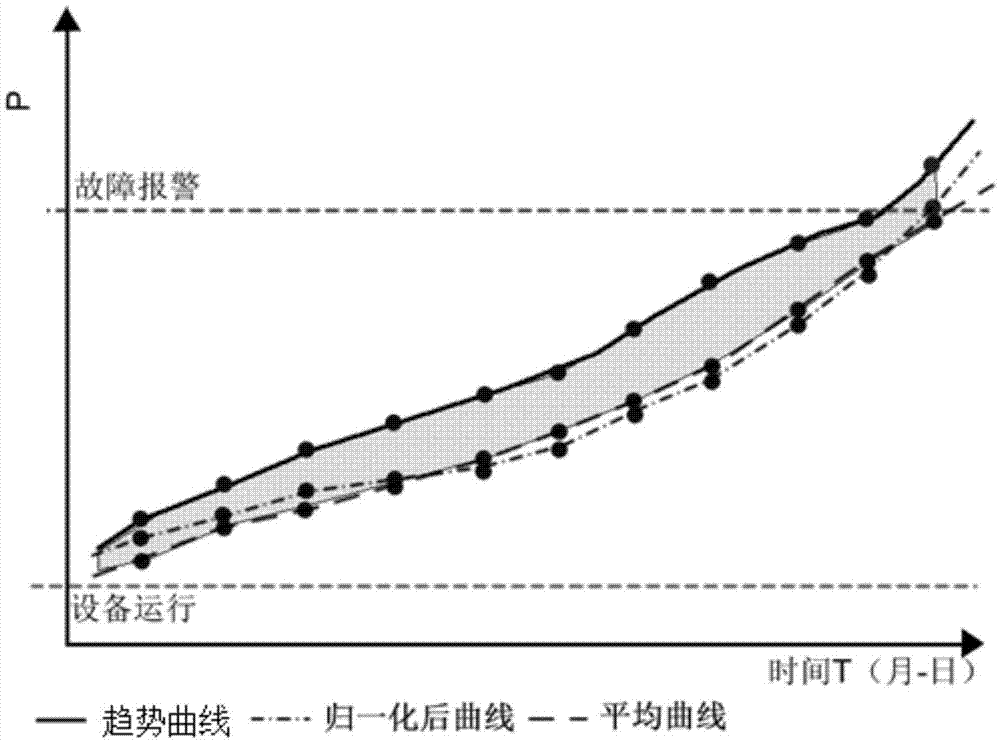

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation of the present invention will be described in detail below by analyzing and comparing the bearings of two field devices of the same type including bearings.

[0035] Such as figure 1 figure 2 As shown, at first, according to the method of the present invention, two bearing parts are processed, and the processing includes the following steps:

[0036] Step 1: Detect the vibration signal of the equipment parts, record the time information of the detection, and perform analog-to-digital conversion on the actual vibration signal to obtain a digital signal sequence;

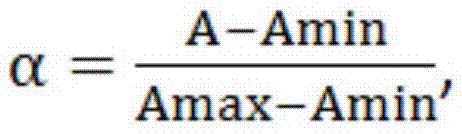

[0037] Step 2: Extract the characteristic parameter P from the digital signal sequence; in the present embodiment, after the vibration signal is subjected to analog-to-digital conversion, fast Fourier transform is performed to find the first-order rotational speed frequency in the frequency spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com