A valve high temperature fatigue testing machine

A fatigue testing machine and valve technology, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as engine performance impact, achieve long service life, high reliability, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

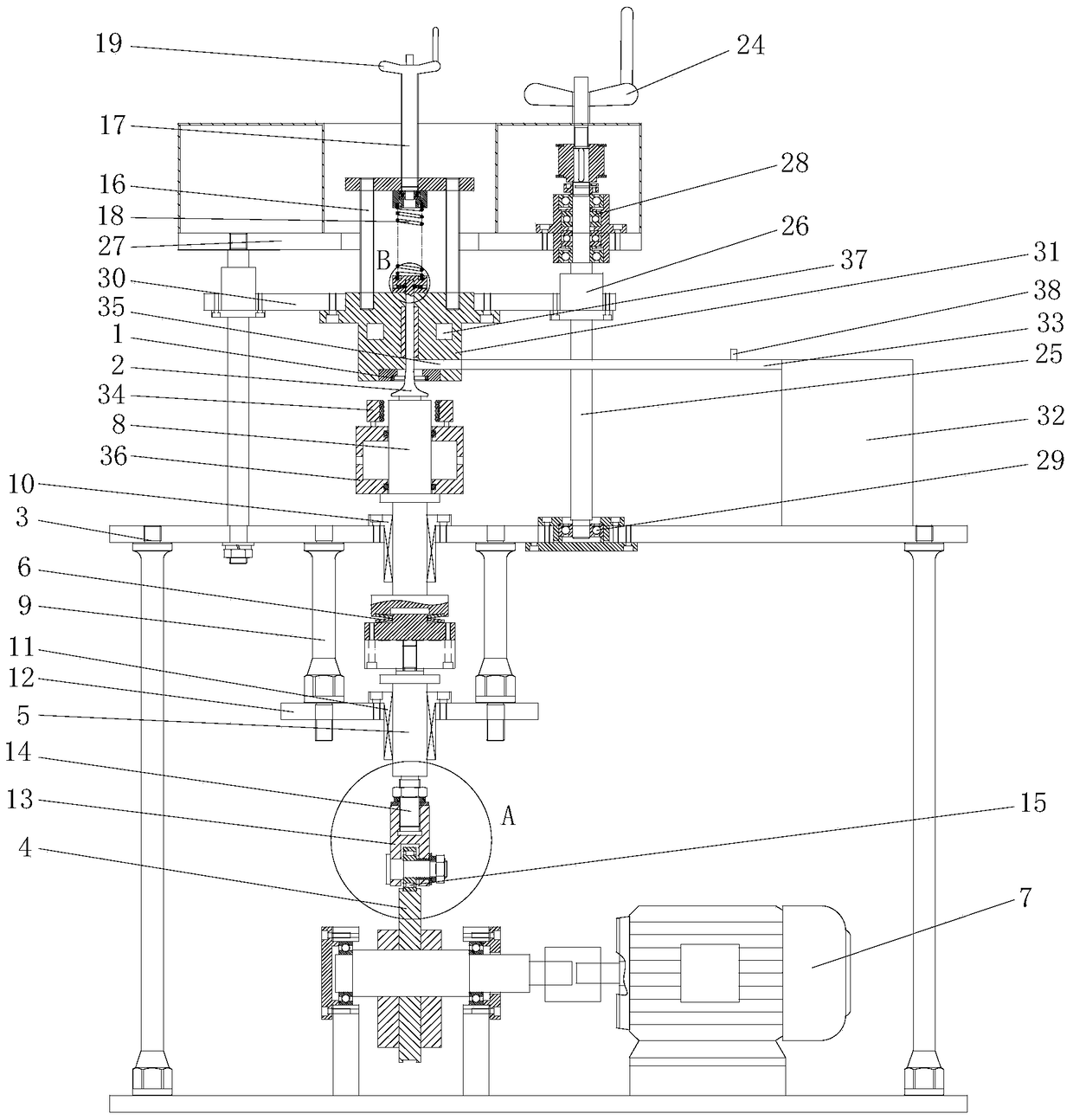

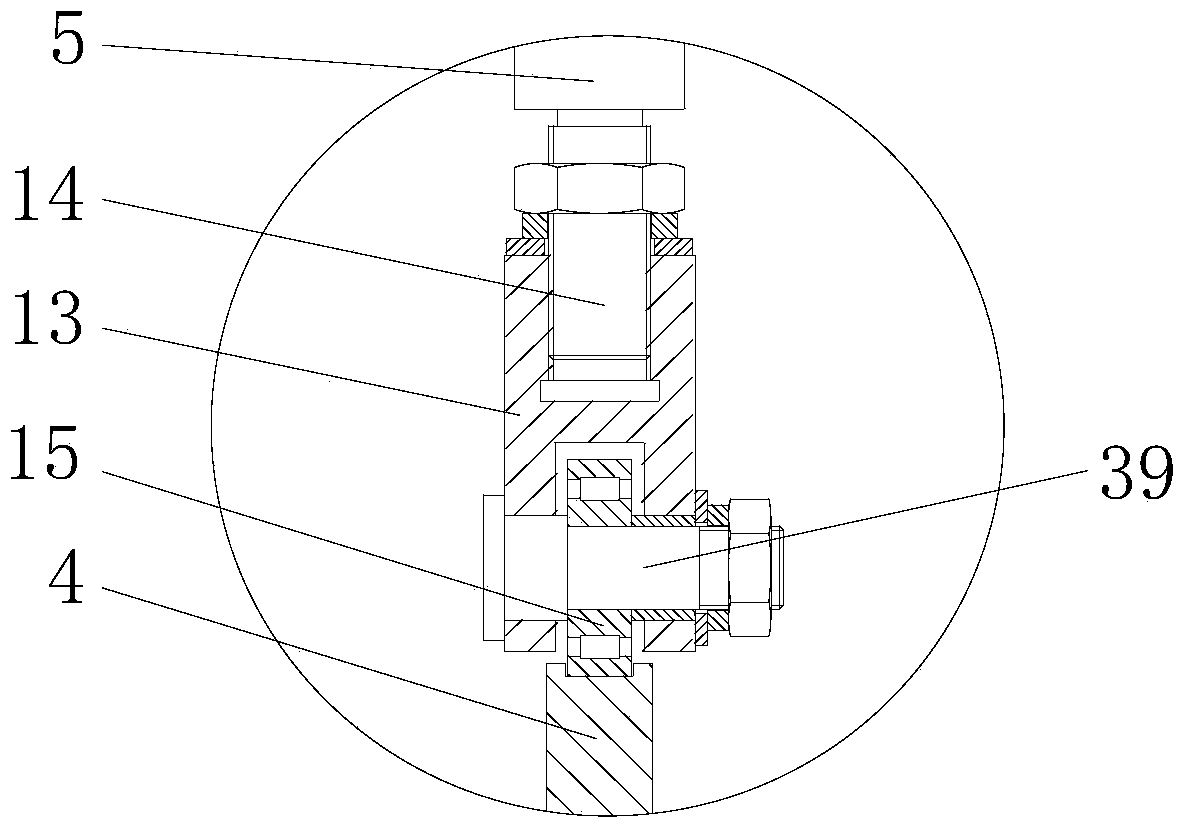

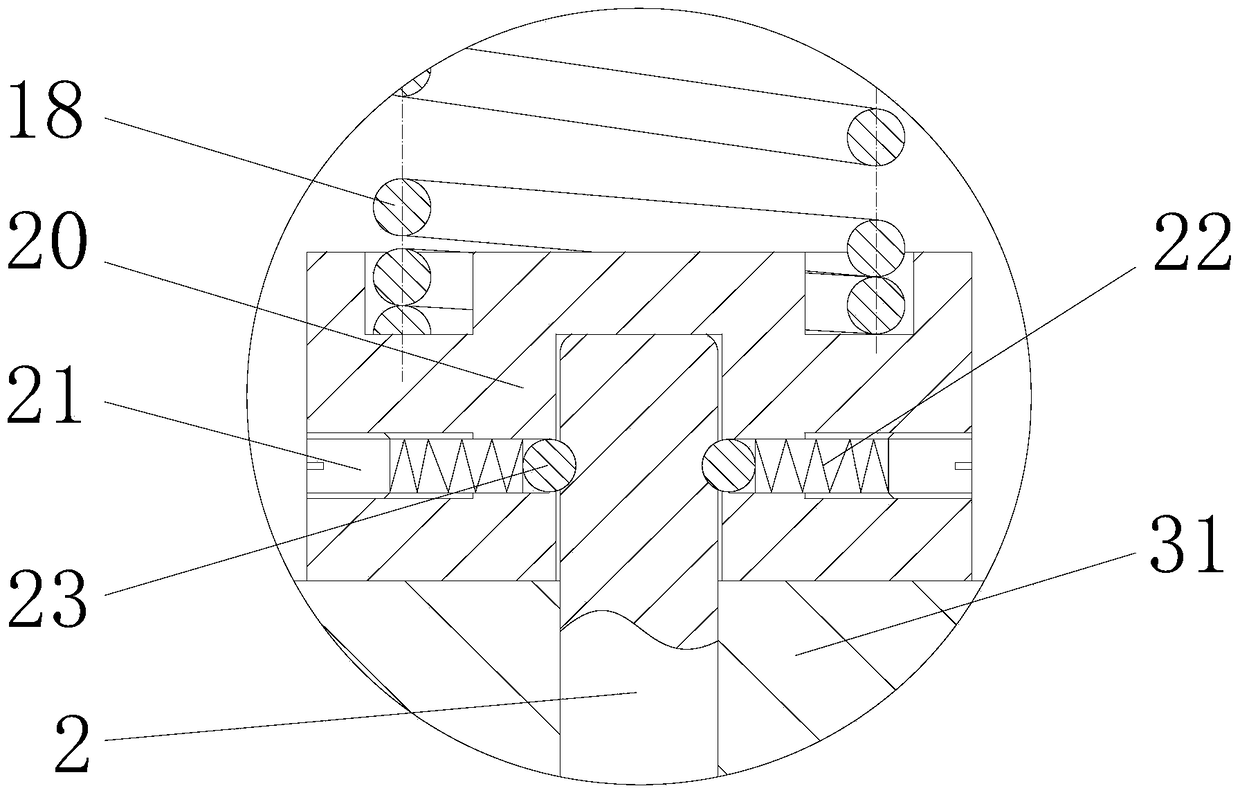

[0026] A valve high-temperature fatigue testing machine, including a valve seat ring 1, a valve 2, an impact loading device, a valve clamping device and a heating system for heating the end face of the valve, the valve seat ring is located above the impact end of the valve, and the impact loading device The device includes an impact frame 3 and an eccentric wheel 4 arranged on the impact frame, a push rod, a disc spring group 6, a drive motor 7, and pushes the valve to impact the valve seat ring while applying force to the valve seat ring through the impact end of the valve. The pressure loading rod 8, the drive motor drives the eccentric wheel to rotate, the lower end surface of the push rod is in contact with the eccentric wheel, the loading rod is arranged above the push rod, the disc spring group is installed between the push rod and the loading rod, the valve clamping device and The valve is connected, and the valve is arranged above the loading rod.

[0027] Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com