Display panel as well as preparation method and application thereof

A technology for display panels and substrates, which can be used in instruments, nonlinear optics, optics, etc., and can solve problems such as deformation of the AA area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A display panel

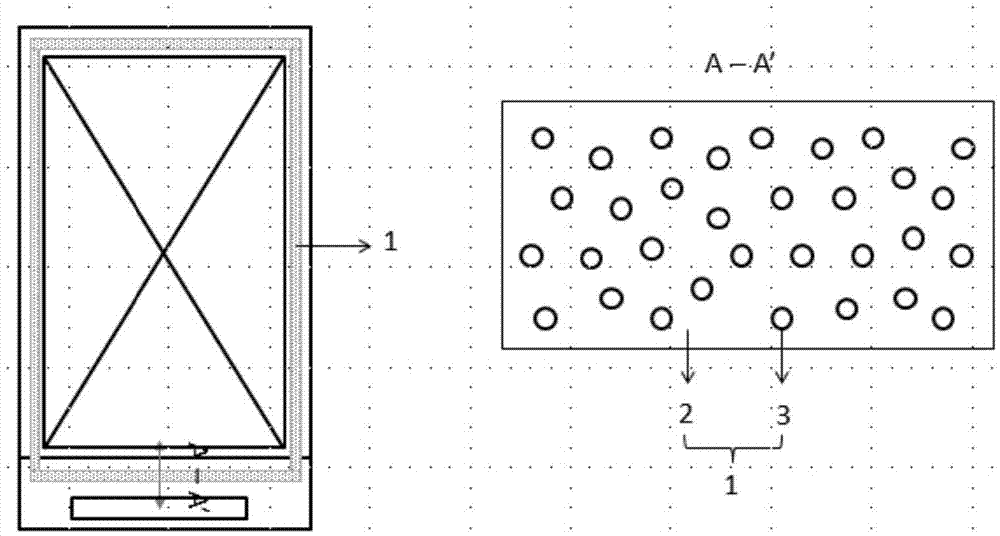

[0040] This embodiment provides a display panel, including a first substrate, a second substrate, and a sealant cured between the first substrate and the second substrate; the sealant includes a matrix material, dispersed in the matrix material thermal phase change materials. The structure of the sealant is as follows figure 1 shown.

[0041] Wherein, the thermally induced phase change material accounts for 4% of the total mass of the sealant.

[0042] Wherein, the thermally induced phase change material is selected from polyurethane block copolymers.

[0043] Wherein, the matrix material is photosensitive resin, photoinitiator, photosensitive crosslinking agent and auxiliary agent.

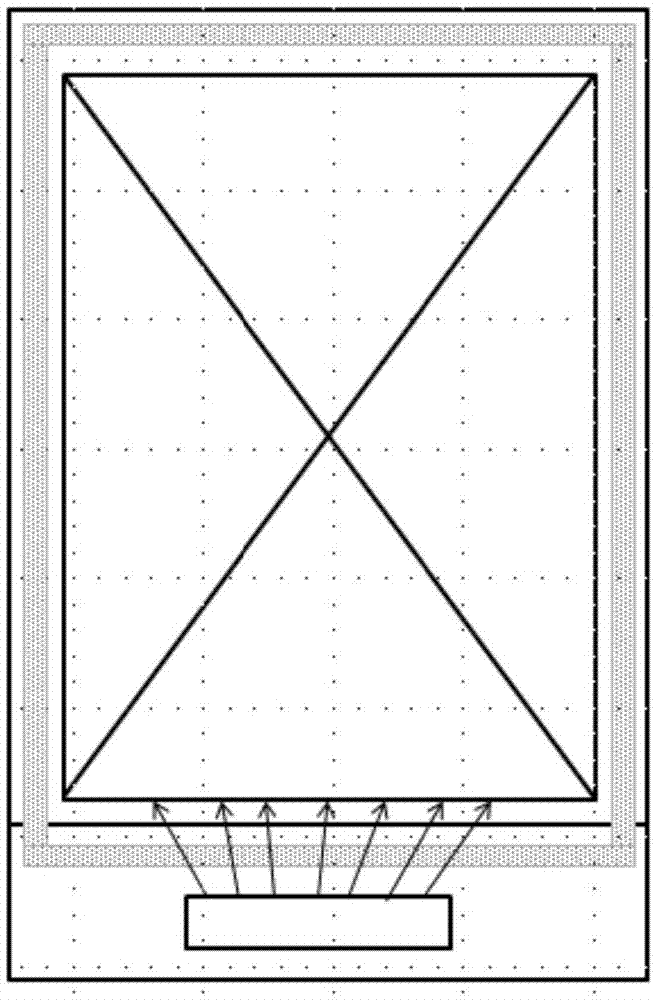

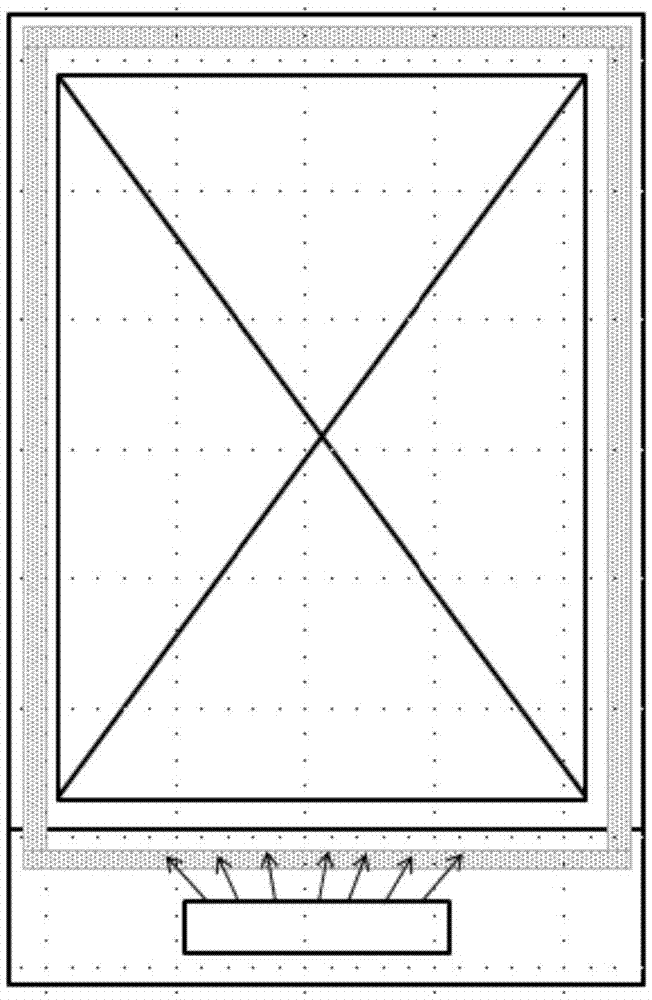

[0044]Since the thermal deformation temperature of glass is about 80°C, and the hot pressing temperature during IC bonding is generally above 200°C, the thermal deformation caused by heat during IC bonding cannot be ignored. The display panel obtained i...

Embodiment 2

[0045] Embodiment 2 A display panel

[0046] This embodiment provides a display panel, using the structure and materials described in Embodiment 1, the difference is:

[0047] (1) The thermally induced phase change material accounts for 0.2% of the total mass of the sealant.

[0048] (2) The thermally induced phase change material is selected from PEG / MDI / glycerol terpolymer cross-linked copolymers.

[0049] The test results show that the display panel obtained in this embodiment has basically the same effect as that in embodiment 1.

Embodiment 3

[0050] Embodiment 3 A display panel

[0051] This embodiment provides a display panel, including a first substrate, a second substrate, and a sealant cured between the first substrate and the second substrate; the sealant includes a matrix material, dispersed in the matrix material Thermally induced phase change materials, conductive gold balls.

[0052] Wherein, the thermally induced phase change material accounts for 12% of the total mass of the sealant.

[0053] Wherein, the thermally induced phase change material is selected from vanadium dioxide.

[0054] Wherein, the matrix material is photosensitive resin, photoinitiator, photosensitive crosslinking agent and auxiliary agent.

[0055] The test results show that the display panel obtained in this embodiment has basically the same effect as that in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com