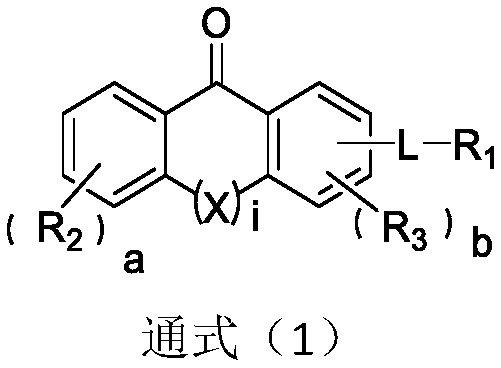

Compound taking anthrone derivative as core and application of compound in OLED device

An anthrone derivative and compound technology, applied in the application field of organic electroluminescent devices, can solve problems such as differences, and achieve the effects of avoiding aggregation, improving device life, and facilitating energy transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The synthesis of embodiment 1 intermediate A

[0053]

[0054] Under nitrogen atmosphere, weigh raw material I, raw material II, KOAc and Pd(dppf)Cl 2 Dissolve in 1,4-dioxane, and react at 130°C for 5 hours. After completion of the reaction, water was added to the reaction mixture, followed by extraction with chloroform. The organic layer was washed with saturated brine, and dried over anhydrous magnesium sulfate to obtain a crude product, which was separated and purified by silica gel column chromatography to obtain the target product.

[0055] The molar ratio of the raw material I to the raw material II is 0.8~2:1; Pd(dppf)Cl 2 The molar ratio of KOAc to raw material I is 0.0018-0.004:1, and the molar ratio of KOAc to raw material I is 2.0-5.0:1.

[0056] Take the synthesis of intermediate A1 as an example:

[0057]

[0058] In a 250mL three-necked flask, nitrogen gas was introduced, and 10.0mol of raw material Ⅰ-1, 12.0mol of raw material Ⅱ-1, 0.3g of Pd(dp...

Embodiment 2

[0063] The synthesis of embodiment 2 intermediate B

[0064]

[0065] Under a nitrogen atmosphere, weigh raw material III and dissolve it in tetrahydrofuran, then add raw material IV and tetrakis(triphenylphosphine) palladium, stir the mixture, then add potassium carbonate aqueous solution, and mix the above reactants at a reaction temperature of 70-90 °C, heat to reflux for 5-20 hours. After the reaction, cooling and adding water, the mixture was extracted with dichloromethane, the extract was dried over anhydrous sodium sulfate, filtered and concentrated under reduced pressure, the obtained residue was separated and purified by silica gel column chromatography to obtain intermediate B;

[0066] The molar ratio of raw material III to raw material IV is 1:1.0 to 1.5, the molar ratio of tetrakis(triphenylphosphine) palladium to raw material III is 0.001 to 0.02:1, and the molar ratio of potassium carbonate to raw material III is 1.0 to 2.0:1 , the ratio of tetrahydrofuran t...

Embodiment 3

[0074] The synthesis of embodiment 3 compound C13

[0075]

[0076] 11.11mmol (3'-chloro-[1,1'-biphenyl]-4-yl)(phenyl)methanone, 7.40mmol 1-(4,4,5,5-tetramethyl-1,3 ,2-dioxaborolan-2-yl)dibenzo[f,H]isoquinoline, 0.101g Pd(OAc) 2 , 7.21mmolCs 2 CO 3 Mix with 14.42mmol Xphos; under the protection of nitrogen, add the above mixture to the mixed solution of toluene / water / ethanol, the volume ratio of toluene / water / ethanol in the mixed solution is 3:1:1, under the condition of 110 ℃, microwave reaction 3 hours. After the reaction was finished, extract the organic layer with dichloromethane, and then use anhydrous MgSO 4 Drying, further separation and purification by TLC (thin layer chromatography) to obtain the target product, HPLC purity 99.8%, yield 66%;

[0077] Elemental analysis structure (molecular formula C 36 h 23 NO): Theoretical C, 89.05; H, 4.77; N, 2.88; O, 3.29; Tested: C, 89.03; H, 4.75; N, 2.86;

[0078] HPLC-MS: The molecular weight of the material is 485....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com