Quantitative analysis method of electrolyte consumption

A quantitative analysis, electrolyte technology, applied in the field of electrolyte analysis, to achieve the effect of strong repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

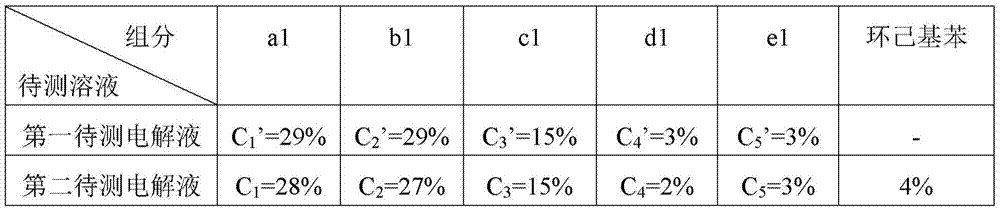

Embodiment 1

[0081] (1) select internal standard substance: according to the component contained in the electrolyte solution 1 of battery 1, select internal standard substance to be cyclohexylbenzene;

[0082] (2) Perform the first pretreatment and the second pretreatment on the two used batteries 1 respectively.

[0083] 1) Two used batteries 1 were obtained through the following charge / discharge cycles:

[0084]Each battery 1 was subjected to the following charge / discharge cycle: at 25°C, the battery 1 was first charged to 4.2V with a constant current of 1C, further charged with a constant voltage of 4.2V to a current of 0.025C, and then charged with a constant current of 1C to 0.025C. The constant current discharges the battery to 3.0V, which is a charge-discharge cycle process. The battery can be charged / discharged 100 times in the above manner,

[0085] 2) Perform the first pretreatment on a battery 1 obtained through the above step 1):

[0086] Disassemble the used battery 1, quic...

Embodiment 2

[0105] (1) Select internal standard: according to the components contained in the electrolyte solution 2 of battery 2, select internal standard to be ethyl acetate;

[0106] (2) Carry out the first pretreatment and the second pretreatment respectively to two used batteries 2:

[0107] 1) Two used batteries 2 were obtained through the following charge / discharge cycles:

[0108] Each battery 1 was subjected to the following charge / discharge cycle: at 25°C, the battery 1 was first charged to 4.2V with a constant current of 1C, further charged with a constant voltage of 4.2V to a current of 0.025C, and then charged with a constant current of 1C to 0.025C. The constant current discharges the battery to 3.0V, which is a charge-discharge cycle process. The battery can carry out 300 charge / discharge cycles according to the above method,

[0109] 2) Carry out the first pretreatment to a battery 2 obtained through the above step 1):

[0110] Disassemble the used battery 2, quickly wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com