Central-positioned type switch chassis overhaul device

A kind of maintenance device, center-mounted technology, applied in the direction of switchgear, electrical components, etc., can solve the problems of dangerous maintenance, time-consuming and laborious, inconvenient disassembly of the switch bottom, etc., and achieve the effect of convenient operation, convenient flipping and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

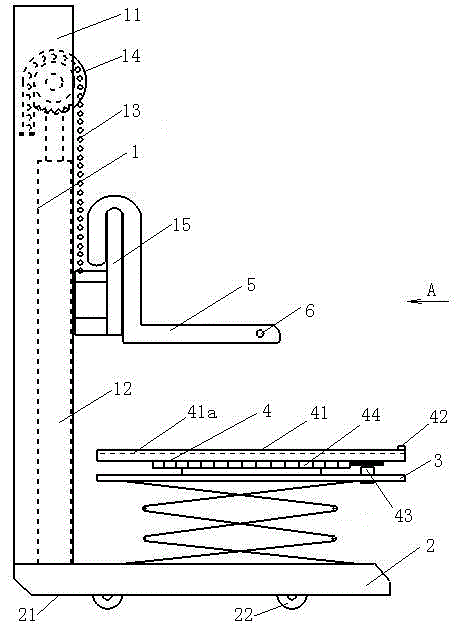

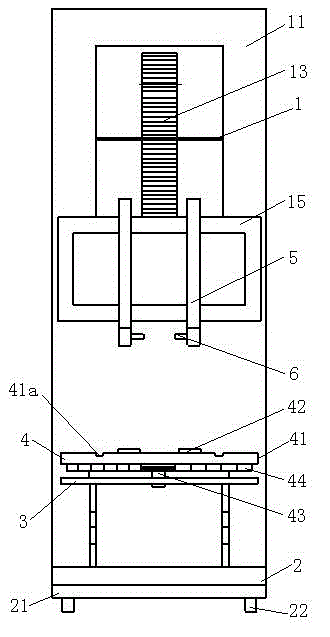

[0014] Refer to attached figure 1 , attached figure 2 , a middle-mounted switch chassis maintenance device of the present invention, which is composed of a lifting device 1, a moving device 2, a lifting table 3, a rotary table 4, a shovel tooth 5, and a pin shaft 6, and the moving device 2 is respectively equipped with a lifting device 1. Lifting platform 3; the lifting platform 3 is provided with a rotary table 4; the shoveling teeth 5 are arranged on the lifting device 1; the pin shaft 6 is fixed on the shoveling teeth 5; the lifting device 1 is composed of a support frame 11, a hydraulic device 12, Transmission chain 13, driving wheel 14, shovel tooth bracket 15 are composed, hydraulic device 12 is arranged on support frame 11, driving wheel 14 is arranged on hydraulic device 12; One end of transmission chain 13 is connected with support frame 11, and the other end is connected with shovel tooth Bracket 15 links to each other, and described shovel tooth bracket 15 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com