Direct-current traction trolley for motor car

A DC traction and EMU technology, applied to switchgear, pull-out switch cabinets, electrical components, etc., can solve problems such as troublesome push and pull, unreliable interlocking, etc., to eliminate potential safety hazards, to ensure reliable connection of circuit breakers, and to avoid misuse The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

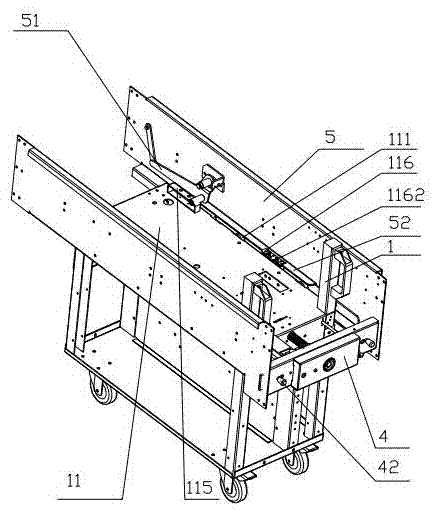

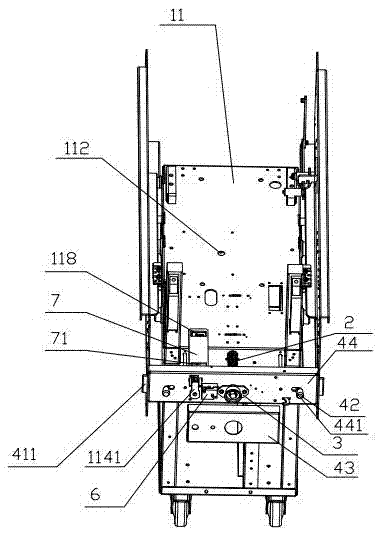

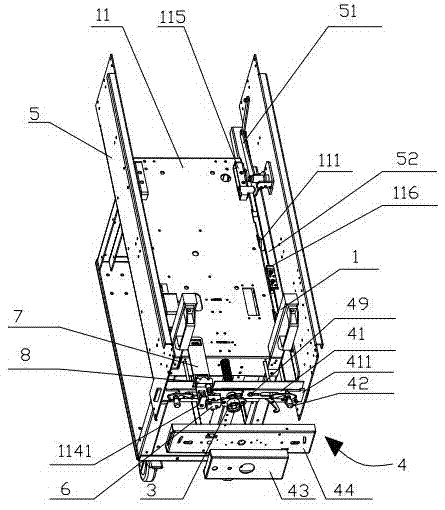

[0038] Embodiment one: see attached figure 1 , 2 , 5-18, the handle 42 includes a driving part 421 inserted into the slide plate 41, a connecting part 422 passing through the positioning frame 44, and a handle part 423 that is convenient to hold, and the connecting part 422 is linked with the handle part 423 , the connecting portion 422 is sheathed outside the driving portion 421 and slidably fits with the driving portion 421 , and the connecting portion 422 is provided with a step 4221 that engages with the positioning frame 44 . With such a structure, when the handle part drives the sliding plate to slide through the driving part, the connecting part pops up under the action of the spring (not shown in the drawing), so that the step is locked with the positioning frame, so that the handle and the end beam are reliably locked together. Avoid skateboarding. Specifically, the positioning frame 44 is provided with a limit locking hole 441 , and the limit locking hole 441 has a...

Embodiment 2

[0039] Embodiment two: see attached Figure 3-18 , the end beam 4 is provided with an interlocking plate 48, and the interlocking plate 48 is provided with a plurality of notch slots 481 (a plurality refers to at least two, and includes two notch slots), the described The handle 42 engages with different notches 481 on the interlocking plate 48 so that the sliding plate 41 is in the first position or the second position. In the present invention, the reliable positioning of the slide plate is realized through the engagement between the handle and the notch on the interlocking plate. When the handle is inserted into one notch, the vehicle frame can be pushed in or withdrawn from the cabinet, and when the handle is inserted into another notch After the handle drives the slide plate to move during the groove, the slide plate makes the screw mandrel rotate to a limited position. The interlocking plate 48 is provided with a limit baffle 482, so that when the interlocking plate mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com