Cable trolley system and cable fixing device

A technology for fixing devices and cables, applied in the direction of electrical components, etc., can solve the problems of poor manufacturability, high manufacturing cost, and the inability to simultaneously compress multiple cables of different sizes and models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

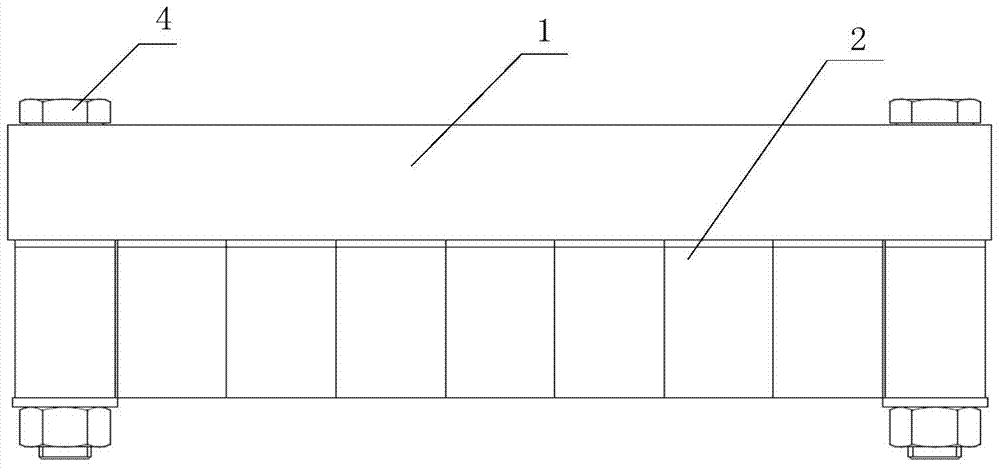

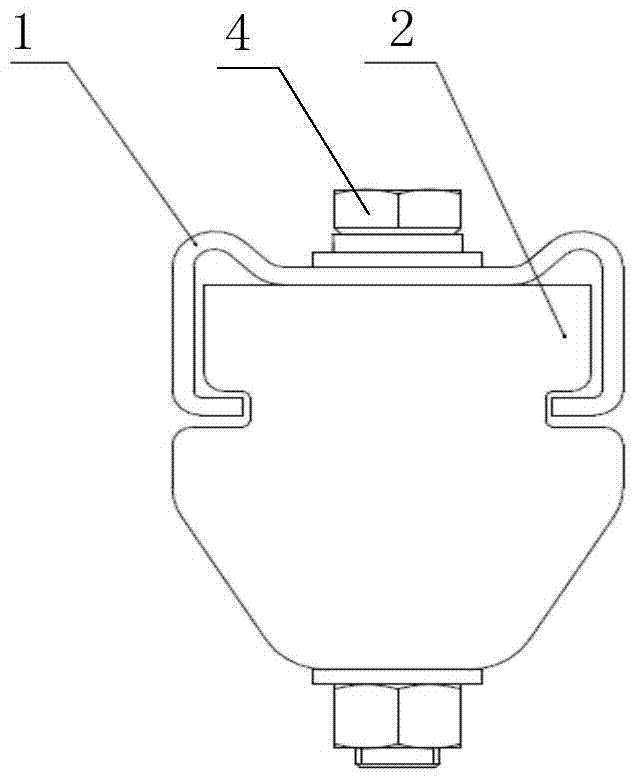

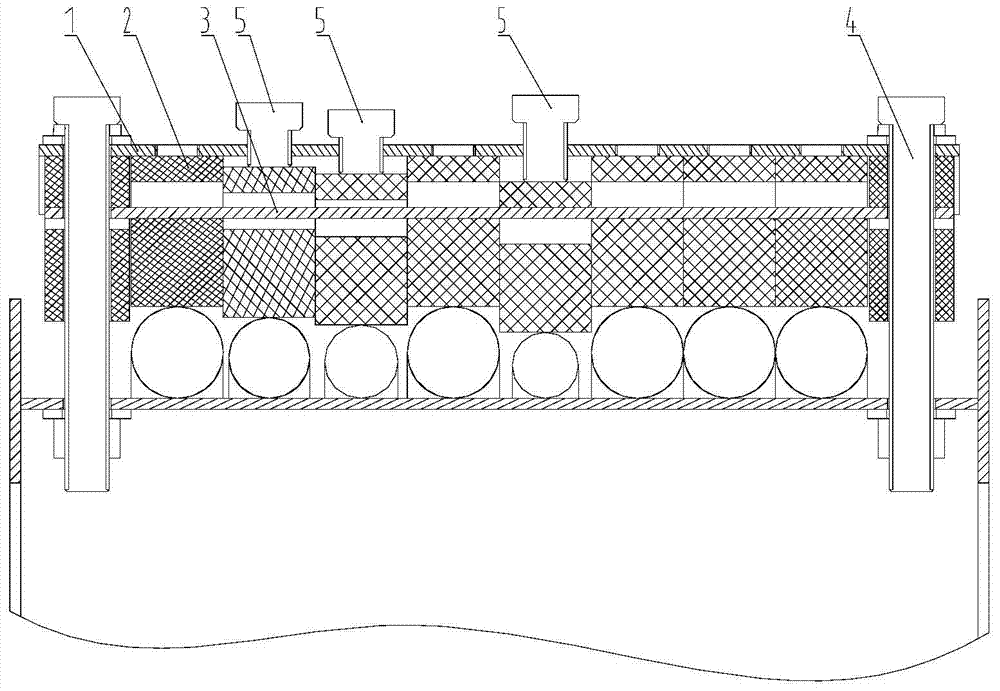

[0033] like image 3 and Figure 4 The cable fixing device shown includes a pressing plate 1, a plurality of pressing blocks 2 are arranged at the bottom of the pressing plate 1, and several pressing blocks 2 are arranged side by side above the cable, a single pressing block 2 is provided with a first through hole in the transverse direction, and the connecting plate 3 passes through several pressing blocks in turn. The first through hole of the pressing block 2 connects several pressing blocks 2, the two ends of the pressing plate 1 and the connecting plate 3 are provided with installation holes, and the pressing blocks 2 located at both ends of the several pressing blocks 2 are vertically prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com