Fluorine-pump internal-circulation secondary refrigerant loop server cabinet heat radiation system

A server cabinet and heat dissipation system technology, applied in the field of fluorine pump internal circulation secondary refrigerant loop server cabinet heat dissipation system, can solve the problems of high energy consumption and inability to dissipate heat from servers, achieve low investment, solve local overheating and hot spots , Noiseless operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

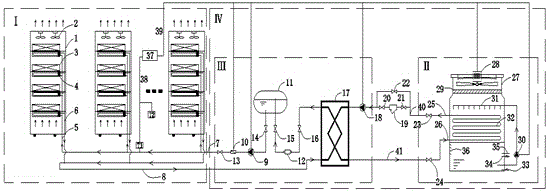

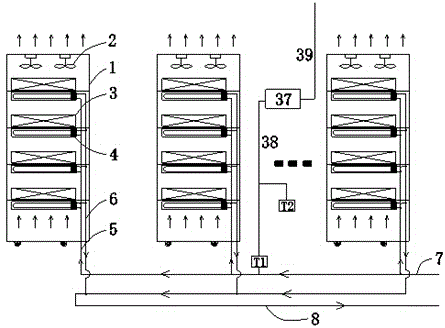

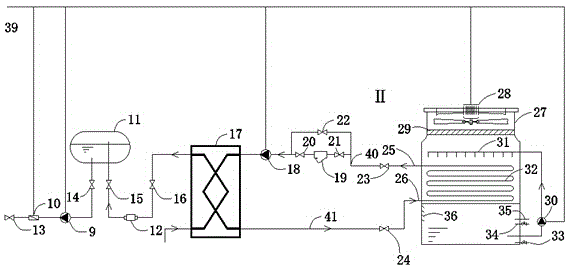

[0039] like figure 1 , a fluorine pump internal circulation type secondary refrigerant loop server cabinet heat dissipation system, including a machine room unit I and a refrigerant supply and return unit IV, the refrigerant supply and return unit IV includes a circulating power unit III and a cooling unit II, the The circulating power unit III forms a closed cycle with the machine room unit I through the first refrigerant loop, and forms a closed cycle with the cooling unit II through the second refrigerant loop.

[0040] Further, the first refrigerant loop is provided with a fluorine supply main pipe 7 of the machine room refrigerant loop and a fluorine return main pipe 8 of the machine room refrigerant loop to connect the machine room unit I and the circulating power unit III respectively. The second cooling coal loop is provided with a refrigerant water supply pipe 25 and a refrigerant water return pipe 26 respectively connected to the circulating power unit III and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com