Method for producing composite molded part and composite molded part

A composite molding, composite part technology, applied in the direction of household components, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effect of improving shear stiffness and bending stiffness, improving compressive strength, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In Figure 1 to Figure 4 In , for the same or similar components or components with the same or similar functions, the same reference numerals are used for the sake of simplicity.

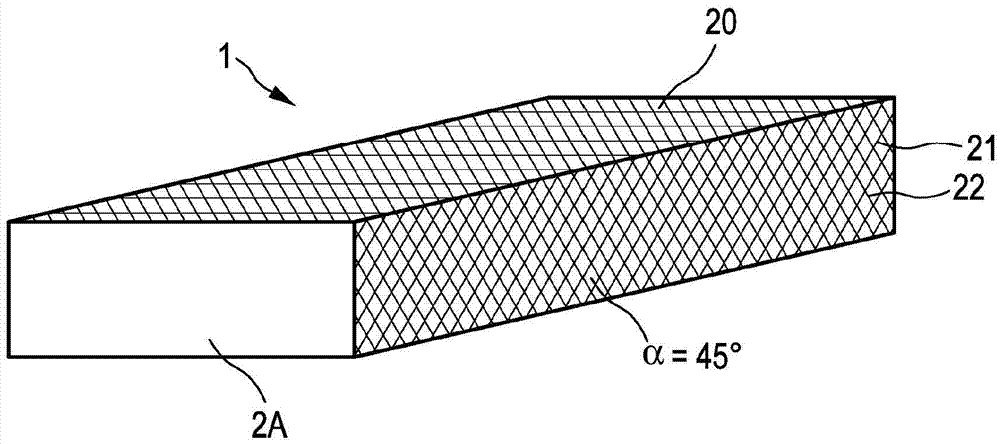

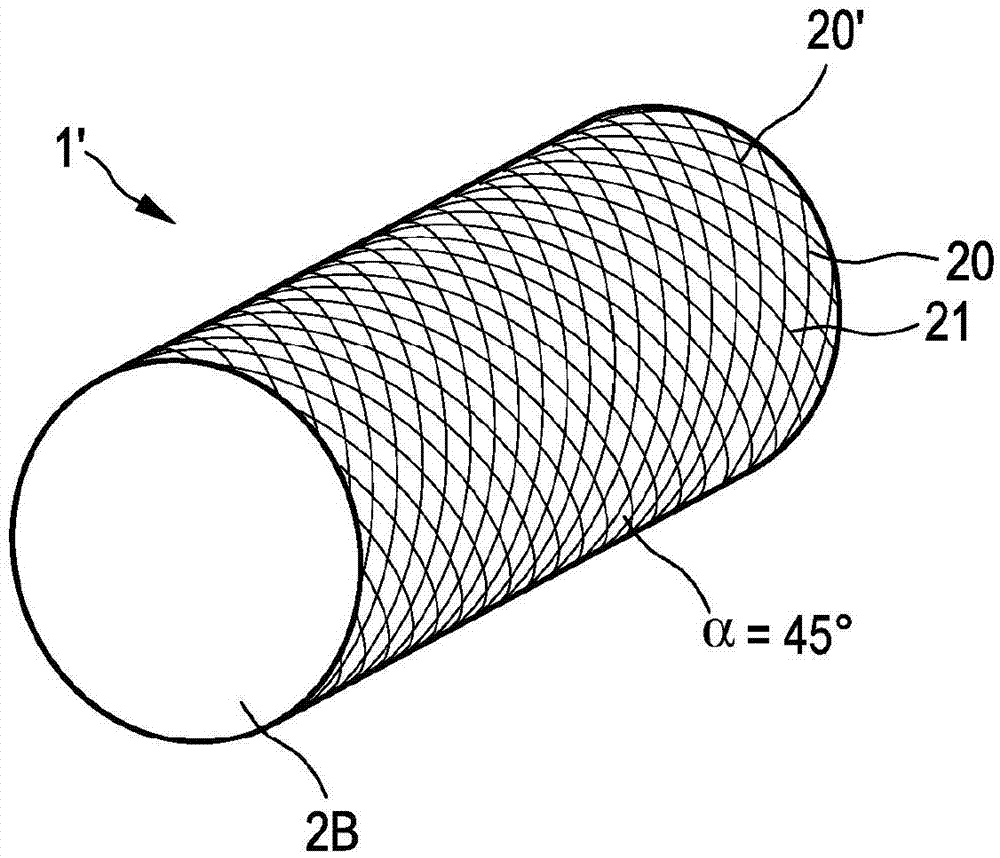

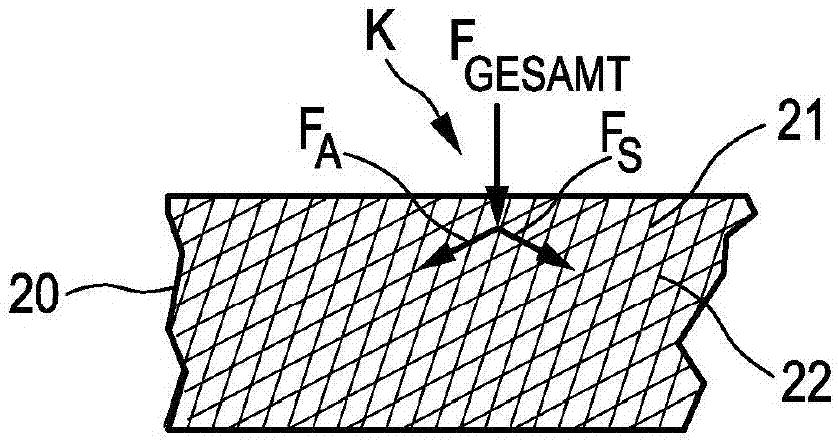

[0075] FIG. 1 shows a composite molded part 1 , which is depicted as a shaped core material 2A in the form of a cuboid. In this case, the braid 20 , in this case a braid mat of glass fibers which is closed as a cuboid jacket, surrounds the cuboid and shows the fibers oriented at a functional fiber angle α of 45° to one another. The individual fibers 21 and 22 here show a fiber angle of α=45° and form a functional force parallelogram on the surface, said force parallelogram with respect to figure 2 Elaborate. Here, a uniform distribution of the fibers is provided in this view. However, it is also conceivable (eg depending on the load distribution) that the fibers 21 , 22 expand differently. A functional orientation in a locally tighter weave can therefore also occur in regions where high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com