Compact fishing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Operation details

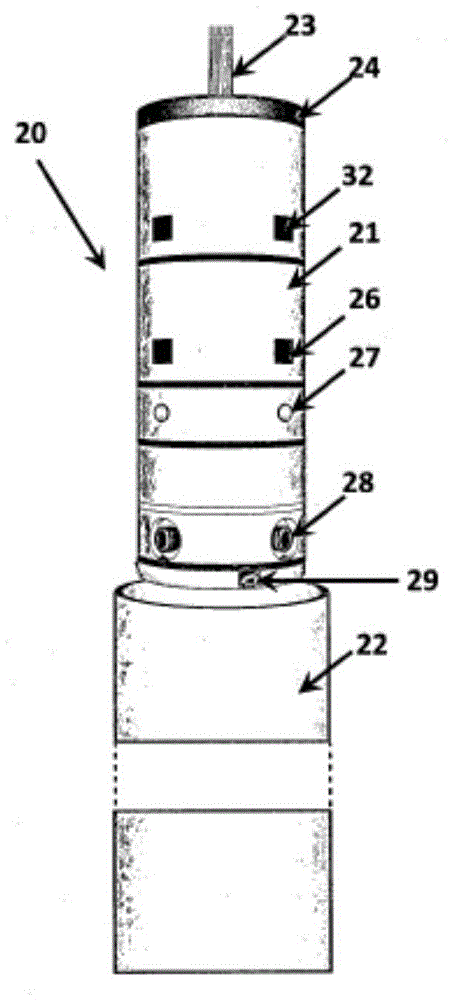

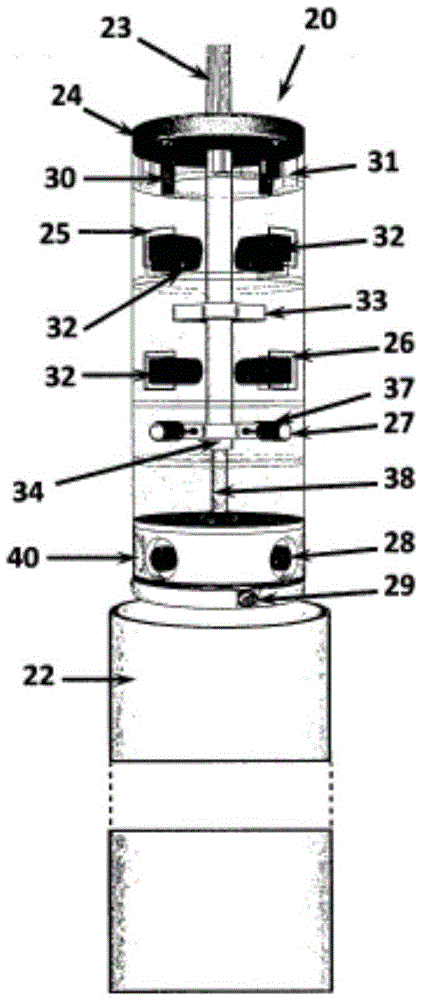

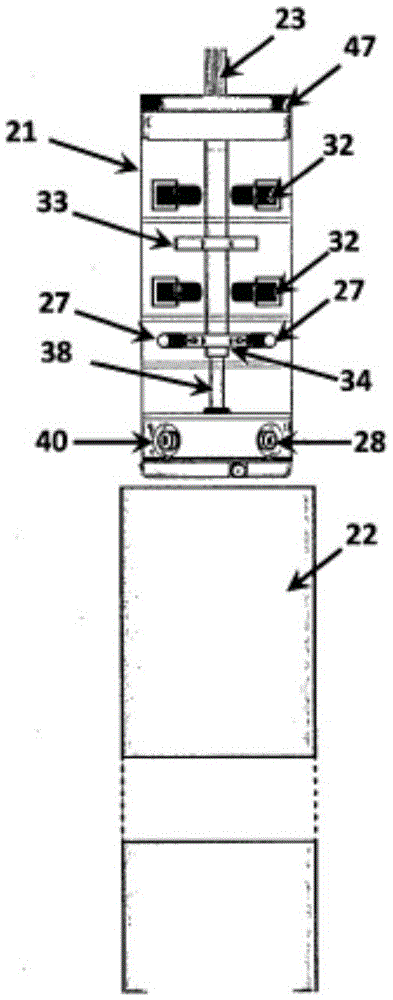

[0022] In order to easily implement the present invention, a detailed description of each component is provided along with the drawings. Because each part has many different characteristics, it can be easily read and understood by quoting the numbers noted in the parts description and list of parts numbers. The arrangement of the zero-accessory number is sequential, and starts from 20; and once the feature of a zero-accessory appears in this article, a serial number will be given directly. For example in figure 1 , the zero-accessory features are arranged in a sequential manner, from 20 to 21, 22, . . .

[0023] Theory of operation / tool / mechanism

[0024] Mechanism 20 here refers basically to a small volume, single entry, single program device, so that it can perform the following programs in a single program: a-cut, b-lubrication, c-vibration (rocking to release drill tube), d-pull up. Therefore, at least the free set of mechanisms should opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com