Cooling device for a headlight of a motor vehicle, in particular for a laser headlight

A technology for cooling devices and motor vehicles, applied in cooling/heating devices of lighting devices, lighting devices, fixed lighting devices, etc., can solve the problems of expensive cooling and electricity demand, and achieve the effect of simplifying assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

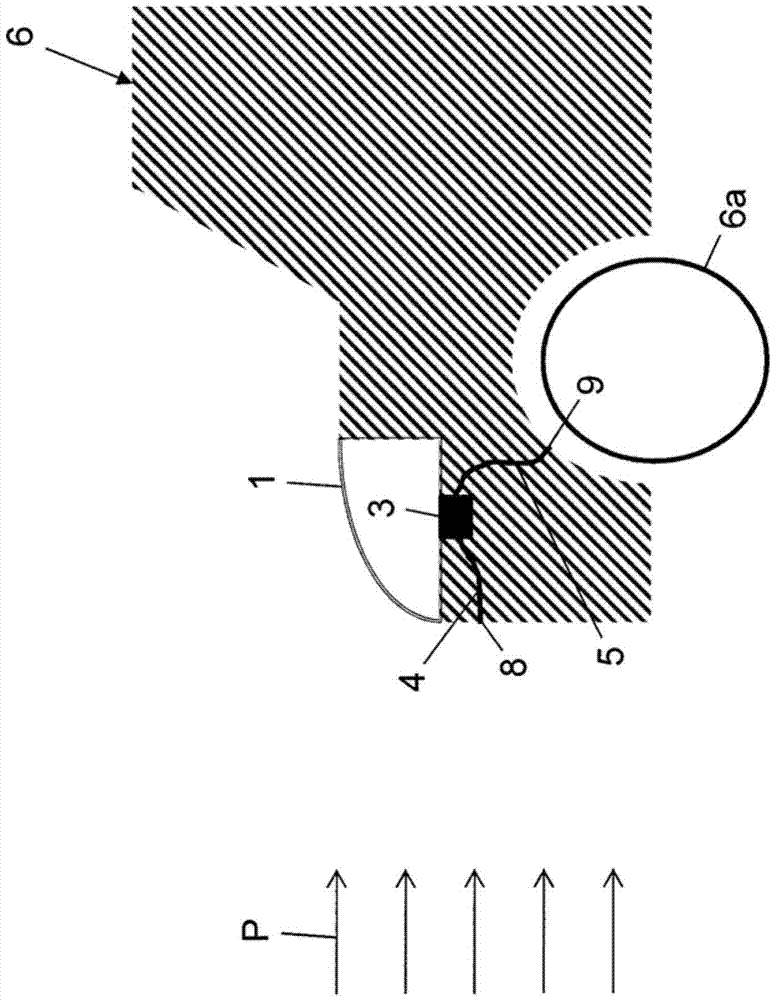

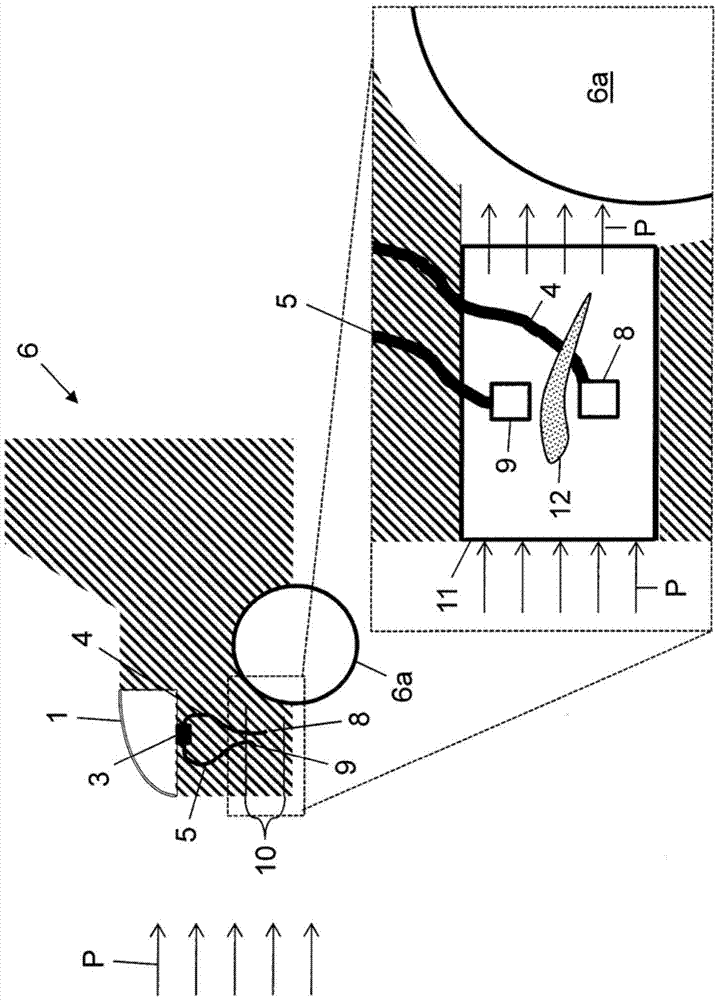

[0028] The following exemplary embodiments of the invention are described below with reference to the cooling of headlights of motor vehicles, wherein the lights for generating a light distribution on a roadway contain a laser module with one or more laser diodes as required. Contrary to conventional LED lighting, cooling requirements are thus increased since laser diodes are limited to operate at ambient temperatures only up to about 70°C, whereas LEDs have an operating range up to about 100°C. In order to ensure adequate cooling of the laser diode, an embodiment of a cooling device will now be described which generates an external air flow in a simple manner without the use of a fan. The corresponding cooling body, which is thermally connected to the laser light source, can be sufficiently cooled by this air flow.

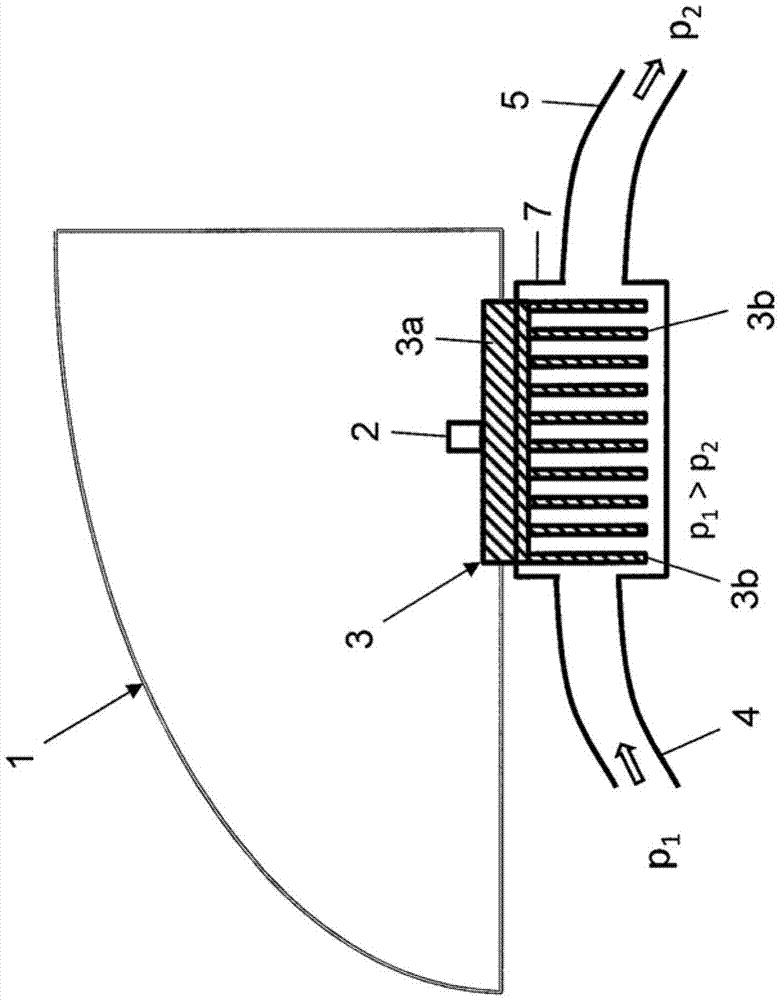

[0029] figure 1 A side view of the front light 1 is shown schematically. In said headlight, a schematically drawn laser diode 2 is provided as a light source, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap