Auto spare part picking device

A technology of auto parts and mounting brackets, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., which can solve the problems of small size, waste, and not allowing personnel to enter, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below by specific embodiments:

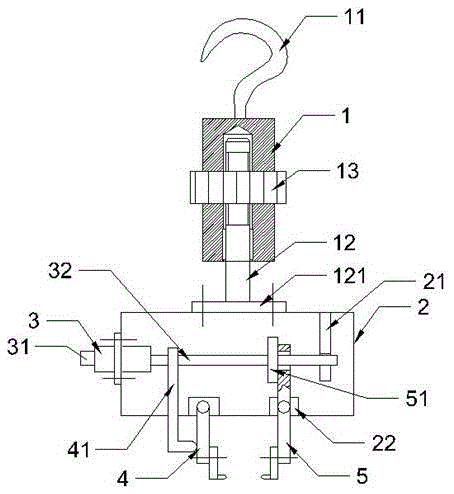

[0013] Reference numerals in the accompanying drawings include: base 1, hook 11, screw 12, mounting plate 121, nut 13, mounting bracket 2, support plate 21, lug plate 22, cylinder 3, pressure reducing valve 31, output rod 32 , Left gripper 4, left block 41, right gripper 5, right block 51.

[0014] The example is basically as attached figure 1 shown:

[0015] The device for picking up auto parts in this solution includes a hoisting mechanism and an installation frame 2. The lower end of the hoisting mechanism is connected to the installation frame 2. The installation frame 2 is used to install the clamping jaws for picking up auto parts. The installation frame 2 is provided with The cylinder 3 with the pressure reducing valve 31 and the supporting plate 21 away from the cylinder 3, the output rod 32 of the cylinder 3 passes through the through hole opened on the supporting plate 21; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com