Railway tunnel lining quality nondestructive detection boom and detection method thereof

A non-destructive testing and lining technology, applied in the direction of claw arm, electromagnetic wave detection, manipulator, etc., can solve problems such as safety accidents, misjudgment of lining defects, and lining quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

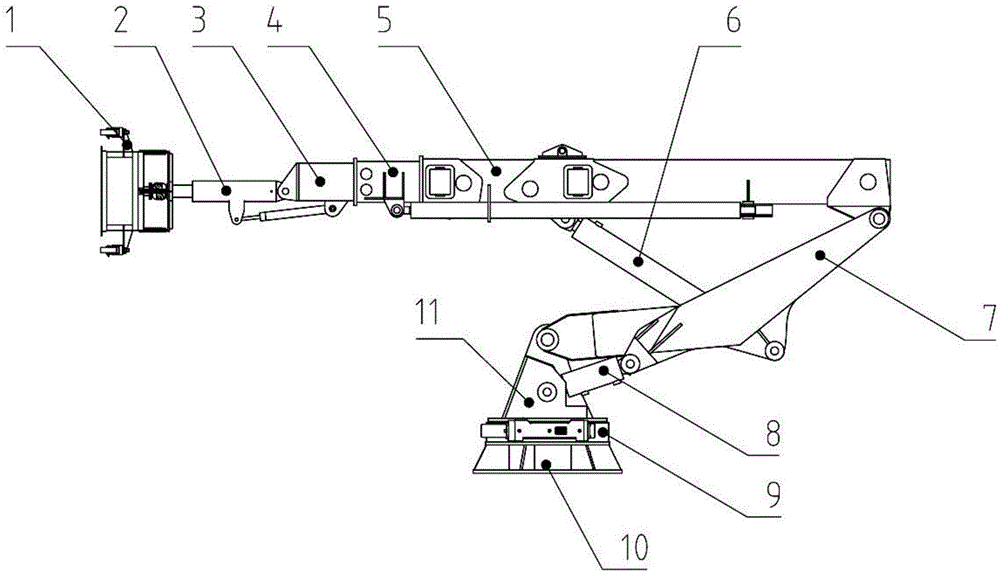

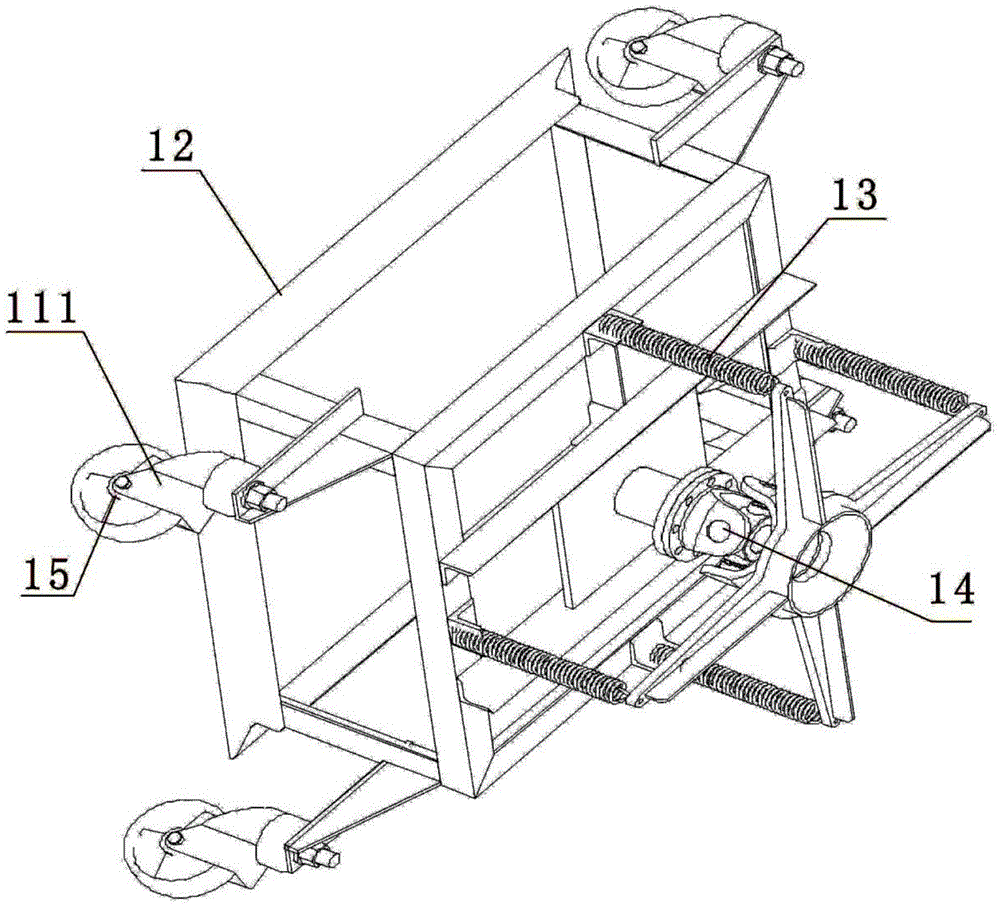

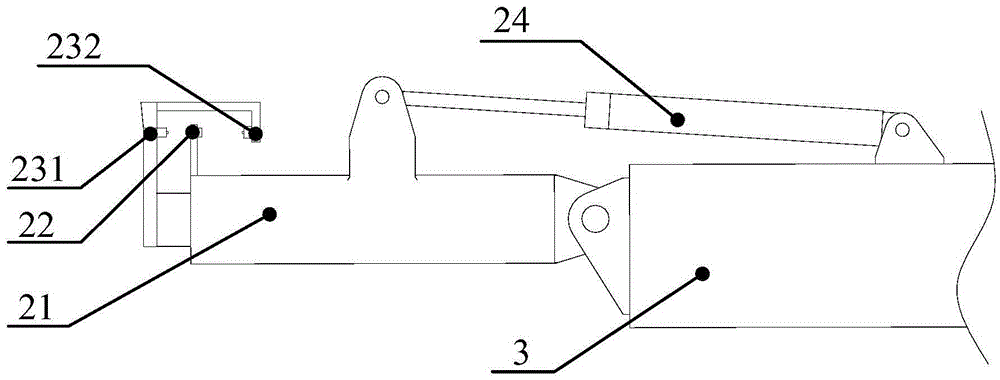

[0074] like Figure 1 to Figure 10 As shown, a railway tunnel lining quality non-destructive testing jib, including radar antenna clamping frame 1, floating buffer cylinder mechanism 2, three-section arm 3, two-section arm 4, basic arm 5, upper pitch luffing cylinder 6, pitch arm 7. Lower pitching and luffing oil cylinder 8, slewing drive device 9, mounting base 10 and slewing base 11, radar antenna is installed on the radar antenna clamping frame 1, the floating buffer cylinder mechanism 2 is connected with the radar antenna clamping frame 1, and the floating buffering Oil cylinder mechanism 2, three-section arm 3, two-section arm 4, and basic arm 5 are connected in turn, and three-section arm 3, two-section arm 4, and basic arm 5 form a telescopic arm mechanism; One end of the two-section boom 4 is hinged, and an upper pitching luffing oil cylinder 6 is correspondingly connected between the pitching arm 7 and the basic arm 5. The pitching arm 7 is hinged on the rotary seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com