Anti-explosion crane hook sleeve

An explosion-proof crane and hook technology, applied in cranes, load hanging components, safety devices, etc., can solve the problems of easy change of hook material, irreplaceable stainless steel skin, affecting the performance of the hook, etc., to prevent flammable and easy explosion accident, ensure the inherent shape and space, the effect of safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

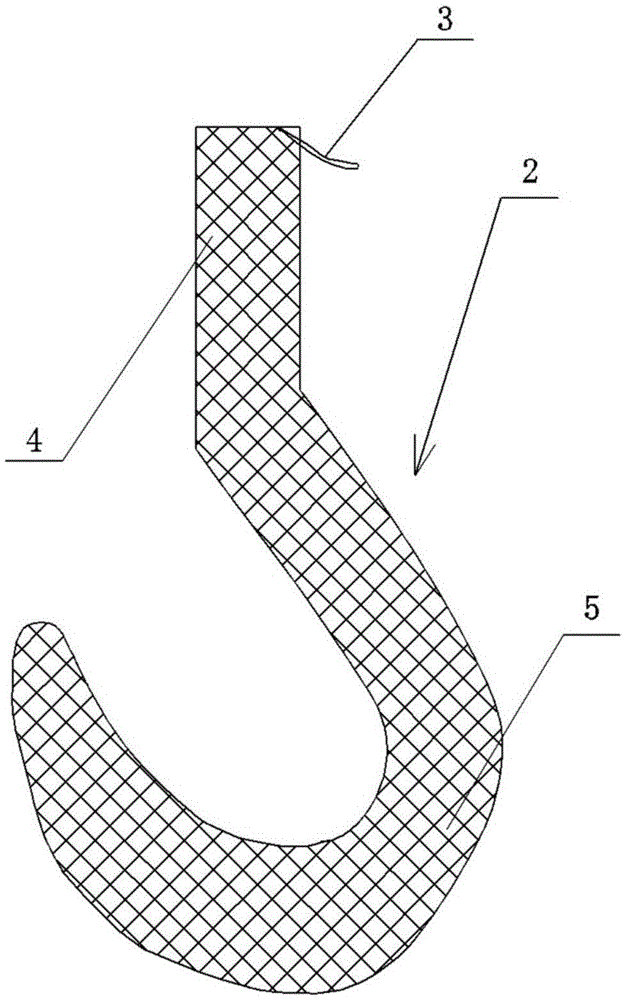

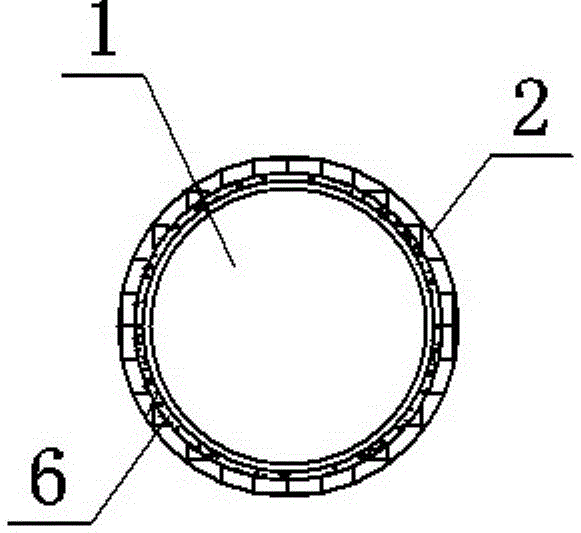

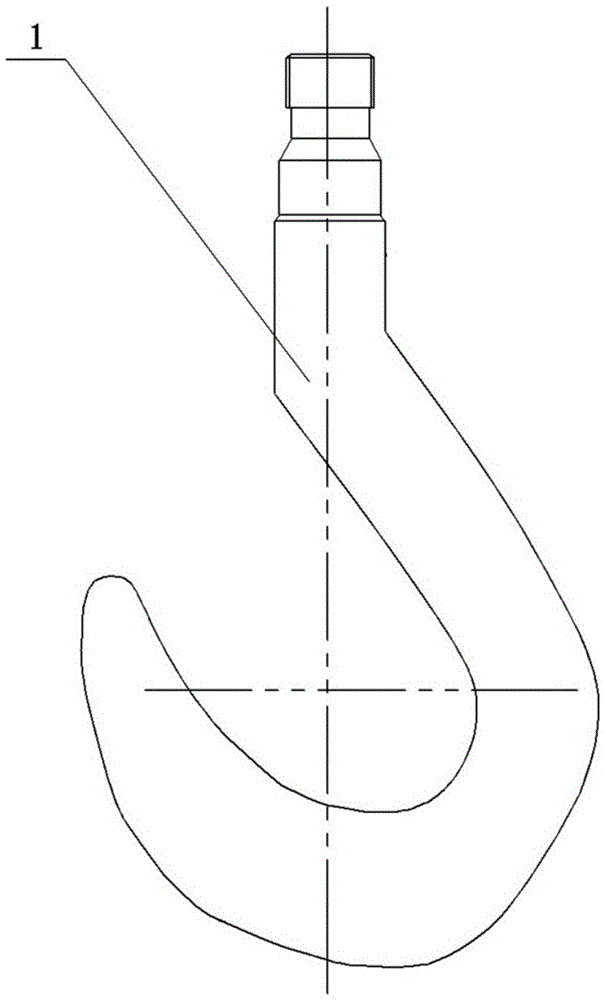

[0013] Embodiment 1: A kind of explosion-proof crane hook cover, see figure 1 and figure 2 , including the sleeve body 2, the overall outline of the sleeve body 2 is the same as figure 1 The shown hook body matches, that is, it is divided into an upper vertical end 4 and a lower hook portion 5 . The sleeve body is made of flexible non-metallic materials interlaced into a grid shape. The non-metallic material is a non-metallic material with tensile, compressive, wear-resistant, flame-retardant, and explosion-proof requirements. The sleeve body is used as a suspension The non-metallic explosion-proof layer of the hook body is fixed together with the hook body 1 by an adhesive 6, and the airtight accommodating chamber surrounded by the cover body matches the shape of the hook body, that is, a cover similar to socks. The inner diameter of the accommodating cavity is slightly smaller than the hook body, so that the sleeve body can be fitted on the hook to achieve seamless fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com