Auxiliary device for untie line

An auxiliary device, the technology of tying thread, which is used in textile and papermaking, weft knitting, knitting and other directions, can solve the problem that the tying thread is not easy to automatically take off, improve the weaving efficiency and product quality, and prevent the hook from hanging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

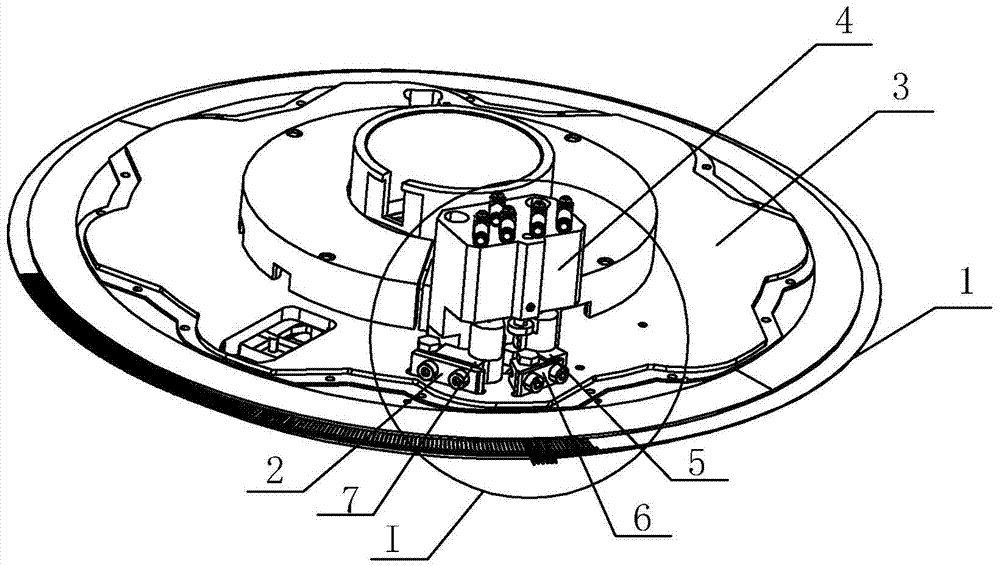

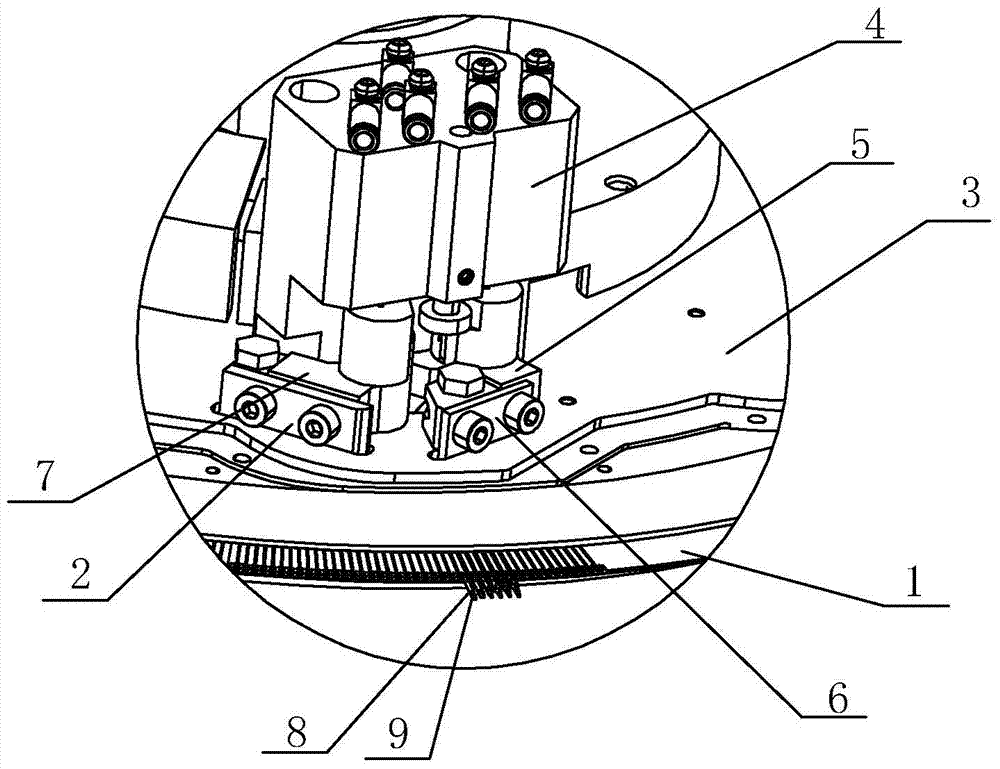

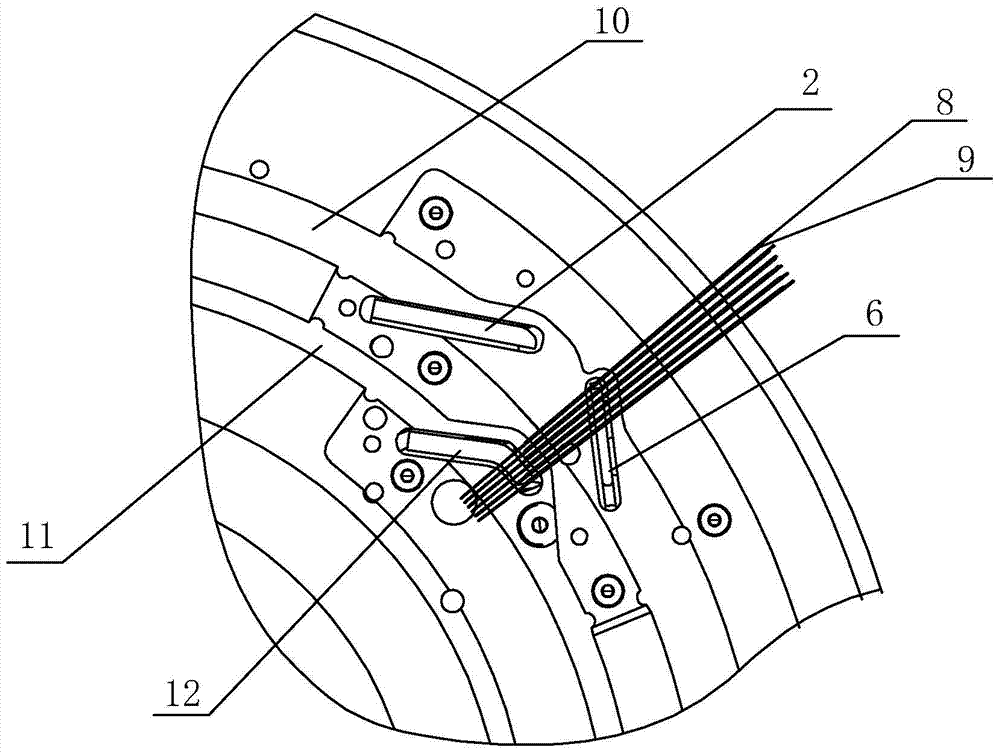

[0014] Such as Figure 1~Figure 5 As shown, the present invention includes a half disk 1, a half needle 8, a half needle triangle assembly, a pneumatic device 4, a mounting plate 3, an auxiliary half needle 9, an auxiliary half needle triangle 12 and an auxiliary half needle triangle seat, A number of radially distributed needle grooves are uniformly arranged on the half plate 1 along the circumferential direction, and the number of said half needles 8 corresponds to the needle grooves and are embedded in the needle grooves one by one. The mounting plate 3 is located on the On the half disk 1 and fixedly installed, the lower end surface of the installation disk 3 is provided with an annular groove coaxial with the half disk 1 as the half needle track 10, and the half needle track 10 is connected to the half needle track 10. The needle butts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com