Anti-seepage structure capable of adapting to settlement of earth and rockfill dam

A technology for earth-rock dams and concrete cut-off walls, applied in dams, barrages, water conservancy projects, etc., can solve problems such as failure of seepage control, loss of life and property, and damage of seepage-proof structures, so as to prevent leakage of the dam body and facilitate construction , The effect of ensuring the safety of the dam body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1 (Take the currently proposed large (2) type reservoir project as an example)

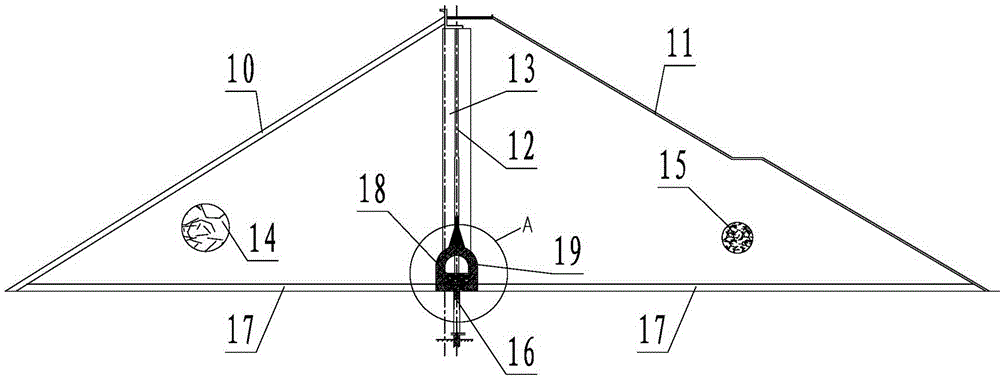

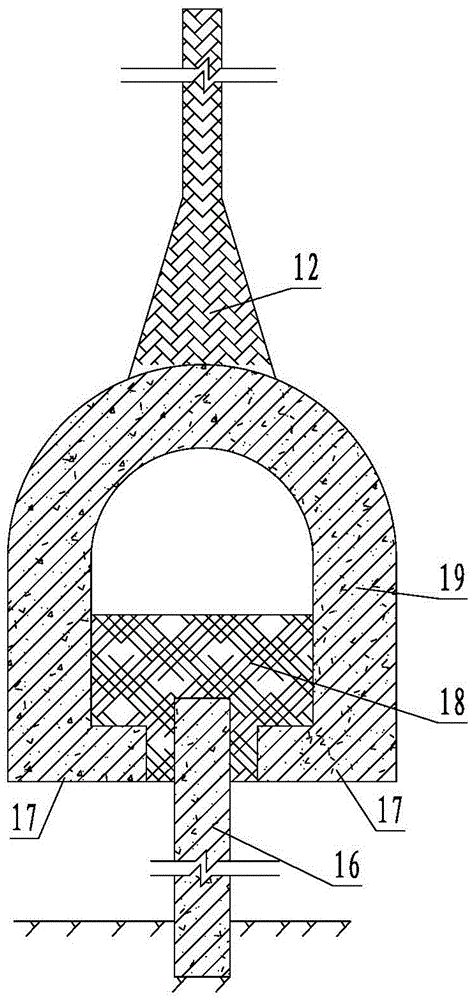

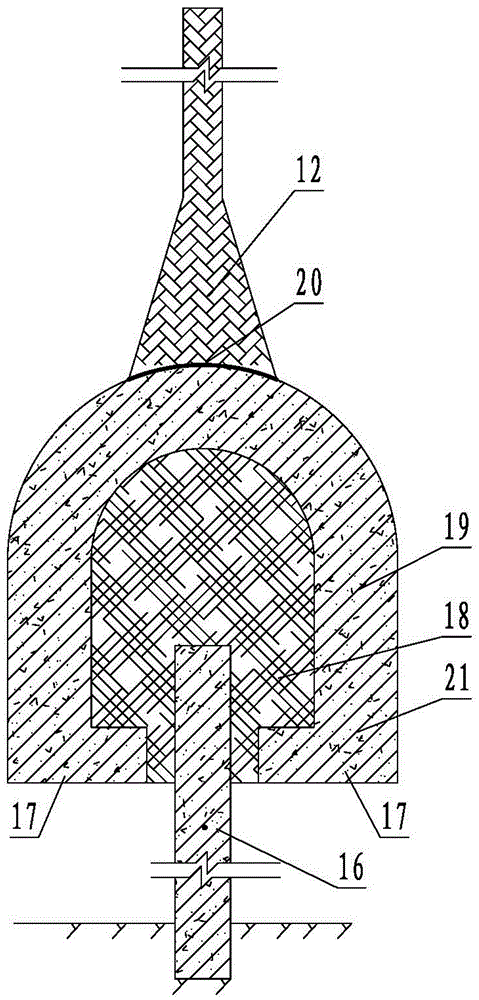

[0029] Depend on Figure 1-5 As shown, 17 in the figure is a dam foundation, 16 is a 1000mm thick concrete cut-off wall, a rockfill dam, and the rockfill dam includes an asphalt concrete core wall 12, a 1000mm thick upstream dry block stone slope protection 10, and a rockfill dam Shell 14, rockfill dam material 15 and downstream dry block stone slope protection 11 with a thickness of 300mm, a concrete cut-off wall 12 is set under the dam foundation 17, an asphalt concrete core wall 12 is set inside the rockfill dam; a concrete cut-off wall 16 There is an arch cutoff wall connection section 19 between the asphalt concrete core wall 12, wherein the top of the concrete cutoff wall 16 is embedded in the arched entrance of the arch cutoff wall connection section 19, and the bottom of the asphalt concrete core wall 12 is set At the arched top of the arched cutoff wall connection sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com