Construction method for major-diameter hollow pile sinking foundation

A construction method and large-diameter technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., to achieve the effects of low cost, simplified construction process, and low project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings.

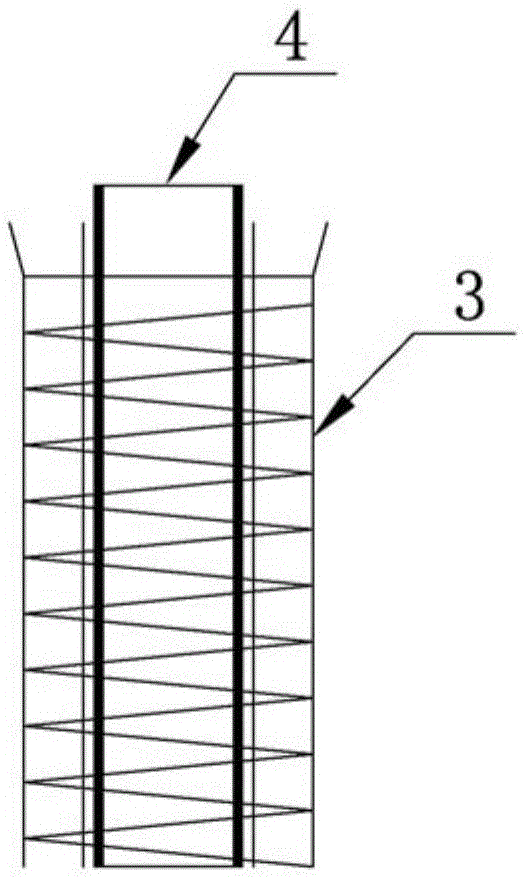

[0023] refer to Figure 1-7 ,

[0024] The construction method of a kind of large-diameter hollow pile foundation of the present invention, concrete steps are as follows:

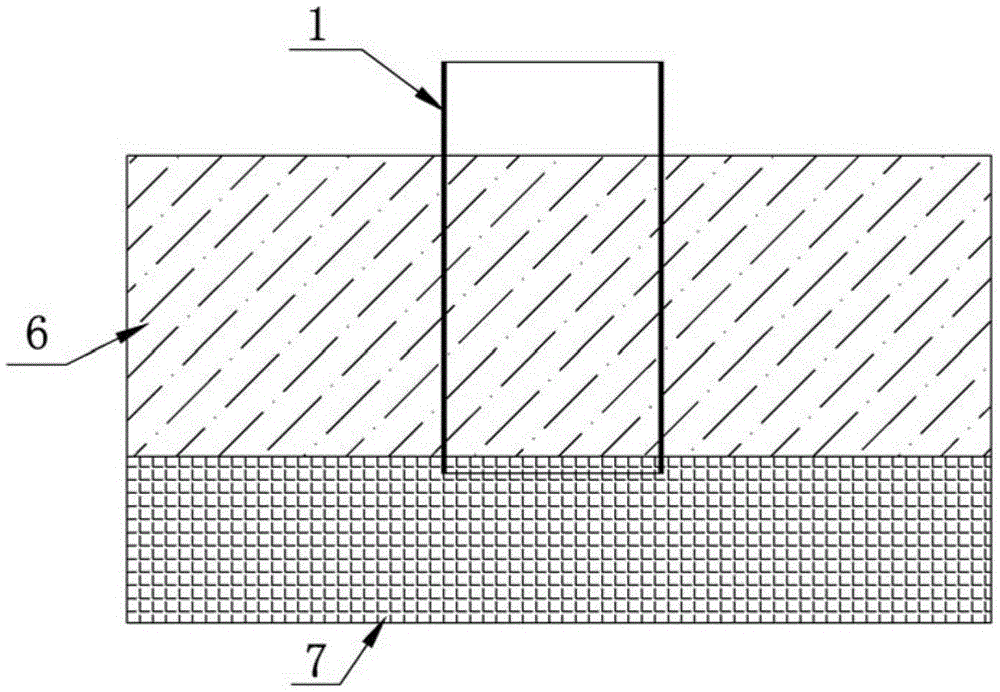

[0025] 1) Vibrating piling hammers are used to drive into the steel casing 1 on the outer wall as the external formwork for concrete pouring of the pile foundation. For large-diameter casings with a diameter ≥ 4m, multiple piling hammers can be used in parallel (see figure 1 ). With the design of the steel casing driven into the outer wall, there will be no problem of hole wall collapse.

[0026] By adjusting the diameters of the outer wall steel casing and the inner temporary casing, the hole forming requirements of pile foundations with different outer diameters and inner diameters can be realized.

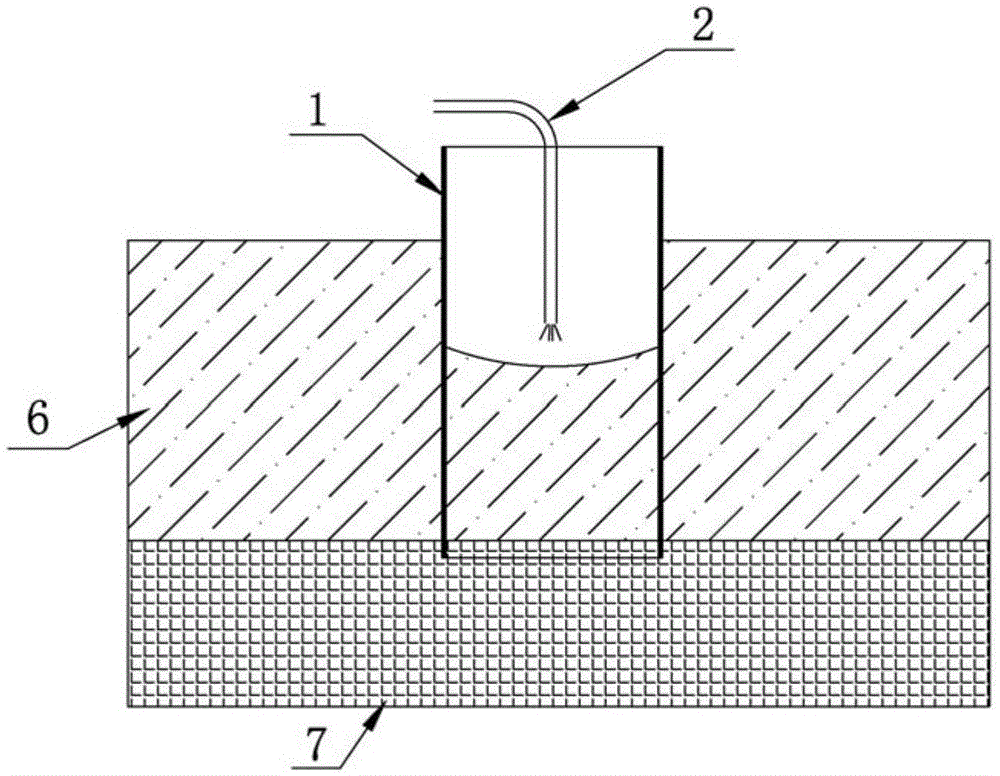

[0027] 2) Install the mud suction pipe 2 in the casing, cooperate with high-pressure water jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com