Pile foundation lining material and construction method of prefabricating prestressed pipe pile using pile foundation lining material

A technology of prestressed pipe piles and construction methods, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., to achieve the effects of reducing production costs, solving environmental pollution, and having obvious environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] A pile foundation lining material, comprising components and their weight proportions, iron tailings: cement: fly ash: water = 4:1:0.15:1.2.

[0087] The prefabricated prestressed pipe pile construction method using the pile foundation lining material comprises the following steps:

[0088] Step 1, pile hole construction:

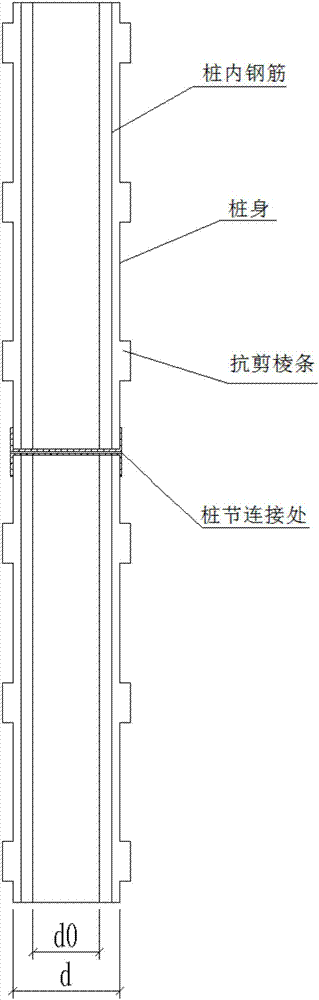

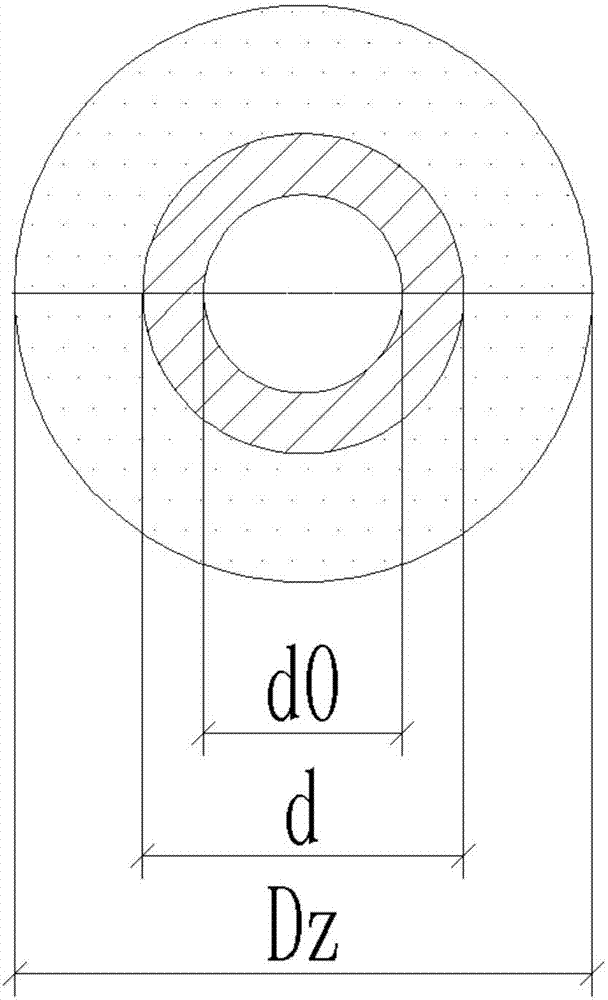

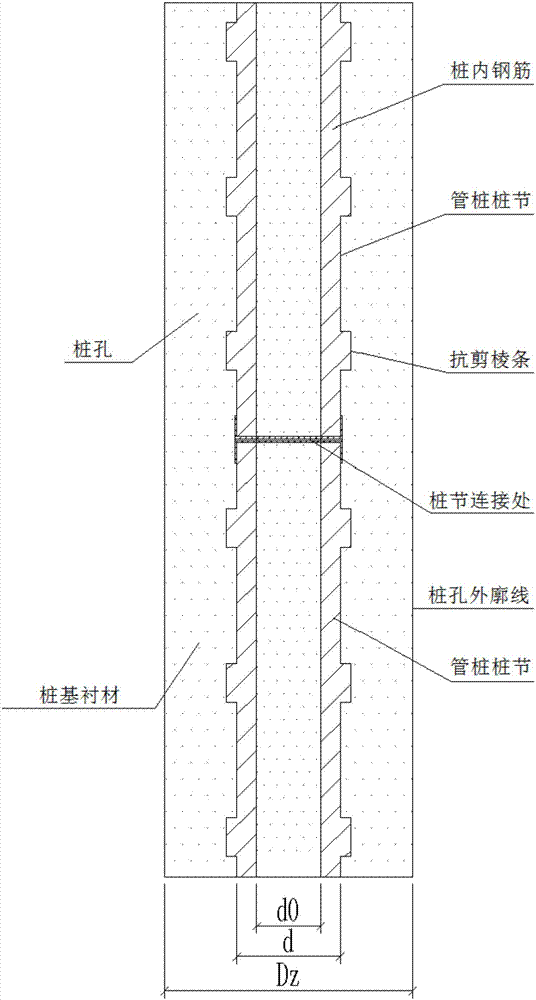

[0089] Use an auger drill to drill pile holes at the corresponding positions. The diameter D and depth of the pile holes are determined according to the design requirements, and the depth of the bottom of the hole reaches the design bearing layer at the pile end;

[0090] Step 2, prepare pile foundation lining material:

[0091] According to the proportion, take respectively, iron tailings: cement: fly ash: water = 4: 1: 0.15: 1.2; after mixing, stir to form composite iron tailings mortar, which is used as pile foundation lining material, wherein iron tailings is Iron tailings that have passed the radiation inspection, the iron tailings are fine ta...

Embodiment 2

[0097] A pile foundation lining material, comprising components and their weight proportions, iron tailings: cement: fly ash: water: retarder = 4: 1.2: 0.15: 1.2: 0.002.

[0098] The prefabricated prestressed pipe pile construction method using the pile foundation lining material comprises the following steps:

[0099] Step 1, pile hole construction:

[0100] Use an auger drill to drill pile holes at the corresponding positions. The diameter D and depth of the pile holes are determined according to the design requirements, and the depth of the bottom of the hole reaches the design bearing layer at the pile end;

[0101] Step 2, prepare pile foundation lining material:

[0102] According to the ratio, take them separately, iron tailings: cement: fly ash: water: retarder, early strength agent or antifreeze = 4: 1.2: 0.15: 1.2: 0.002; after mixing, stir to form a composite iron tailings mortar , as the pile foundation lining material, wherein the iron tailings are iron tailings...

Embodiment 3

[0108] A pile foundation lining material, including components and their weight ratios, iron tailings: cement: fly ash: water: early strength agent = 5:1:0.15:1.4:0.015.

[0109] The prefabricated prestressed pipe pile construction method using the pile foundation lining material comprises the following steps:

[0110] Step 1, pile hole construction:

[0111] Use an auger drill to drill pile holes at the corresponding positions. The diameter D and depth of the pile holes are determined according to the design requirements, and the depth of the bottom of the hole reaches the design bearing layer at the pile end;

[0112] Step 2, prepare pile foundation lining material:

[0113] According to the proportion, take them separately, iron tailing sand: cement: fly ash: water: early strength agent = 5: 1: 0.15: 1.4: 0.015; after mixing, stir to form a composite iron tailing sand mortar, which is used as a pile foundation lining material. Wherein, the iron tailings are iron tailings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com