One-time hole cleaning device and hole cleaning method for bored piles

A bored pile cleaning technology, which is applied to sheet pile walls, buildings, foundation structure engineering, etc., can solve problems such as inability to ensure thorough hole cleaning, difficult removal of sludge, failure to achieve the purpose of hole cleaning, etc., and achieve pile The end bearing capacity can be fully exerted and the quality of the pile body can be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

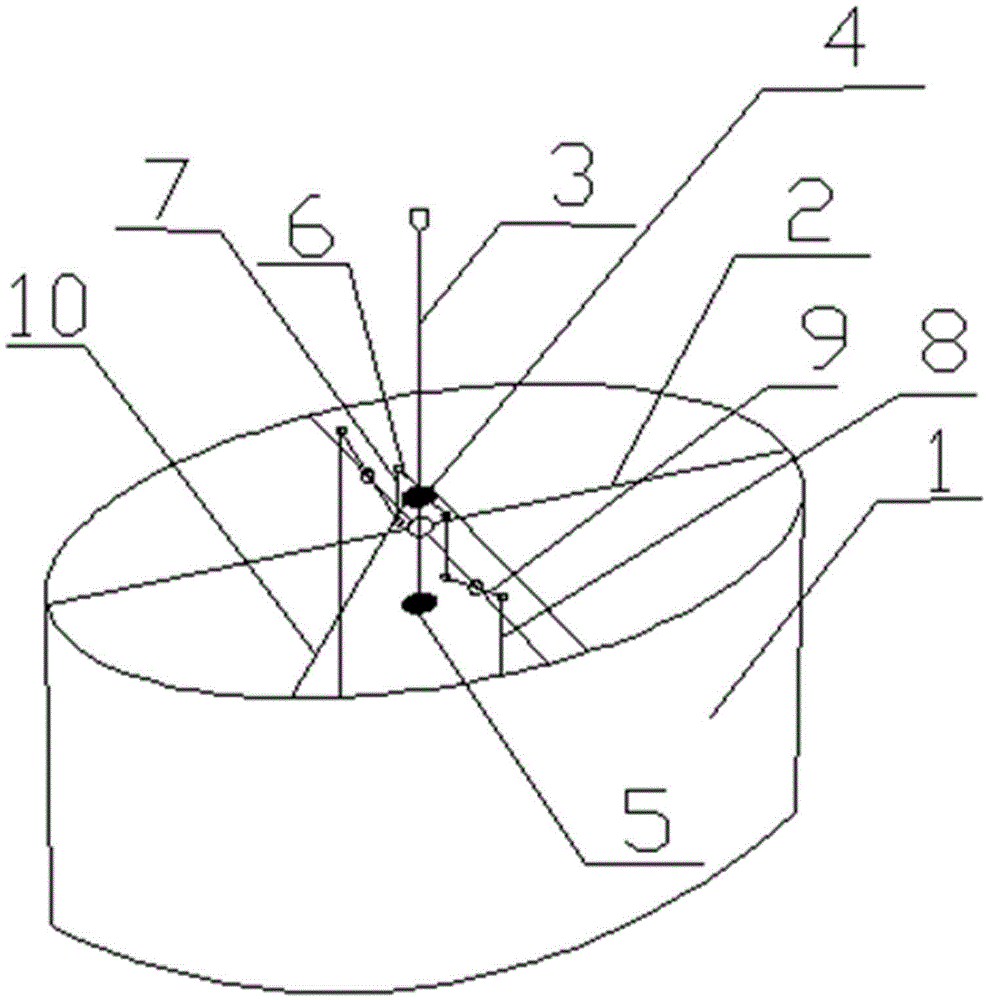

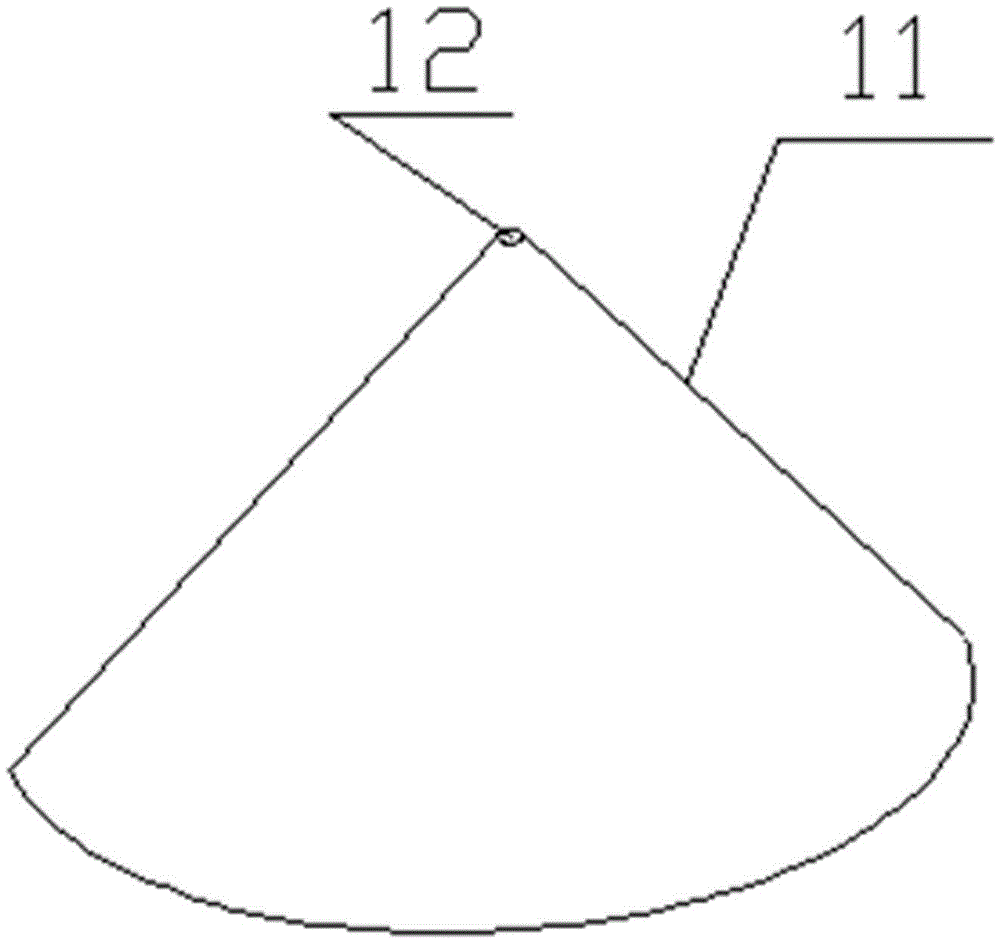

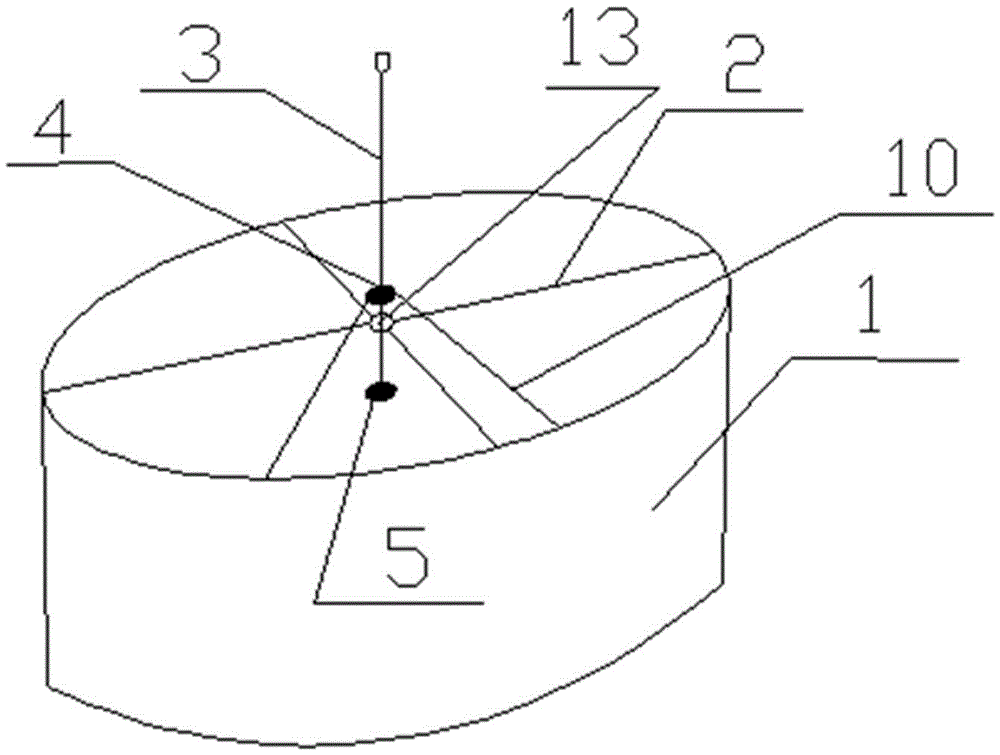

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] Such as Figure 1-13 As shown, the once-cleaning device for bored piles of the present invention consists of a slag collecting barrel 1, an upper horizontal frame 2 of the slag collecting barrel, a kelly 3, a kelly upper baffle 4, a kelly lower baffle 5, Horizontal support rod 6, first vertical support rod 7, second vertical support rod 8, oblique support rod 9, oblique push rod 10, umbrella-shaped slag collection bucket cap 11, umbrella-shaped slag collection bucket hat top square hole 12 , square hole 13, slag retaining plate 14, chute 15, side plate 16 of the overhanging slag collection mechanism, top plate 17 of the overhang slag collection mechanism, bottom plate 18 of the overhang slag collection mechanism, shaft 19 of the overhang slag collection mechanism, horizontal push rod 20. Horizontal push rod guide ring 21, extension spring of slag collection mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com