Aluminum-plastic-coextrusion heat-conducting floor

A heat-conducting floor and floor technology, which is applied in the field of building decoration materials, can solve the problems of high cost, heavy weight, and unsightly appearance, and achieve the effects of improved fluidity, long service life, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

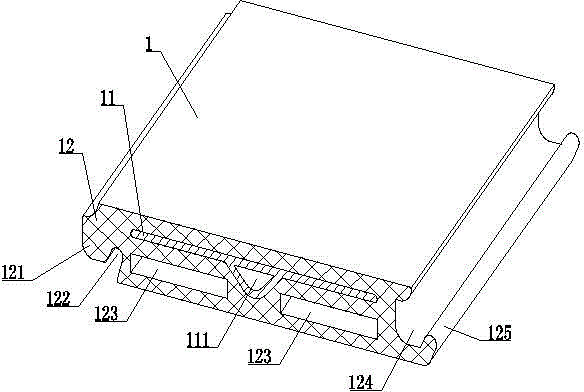

[0007] see figure 1 , the present invention includes a floor 1, the floor 1 includes an aluminum core 11 and a coating 12 coated on the outer surface of the aluminum core 11, the aluminum core 11 is provided with a triangular hole 111, the core of the cladding 12 Two side-by-side rectangular holes 123 are arranged on the top, a large elbow 121 and a small groove 122 are provided at the left end of the floor 1 , and a large groove 124 and a small elbow 125 are provided at the right end of the floor 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com