Connecting rod for internal combustion engine

一种内燃机、连杆的技术,应用在连杆、连杆轴承、活塞杆等方向,达到减小面压的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

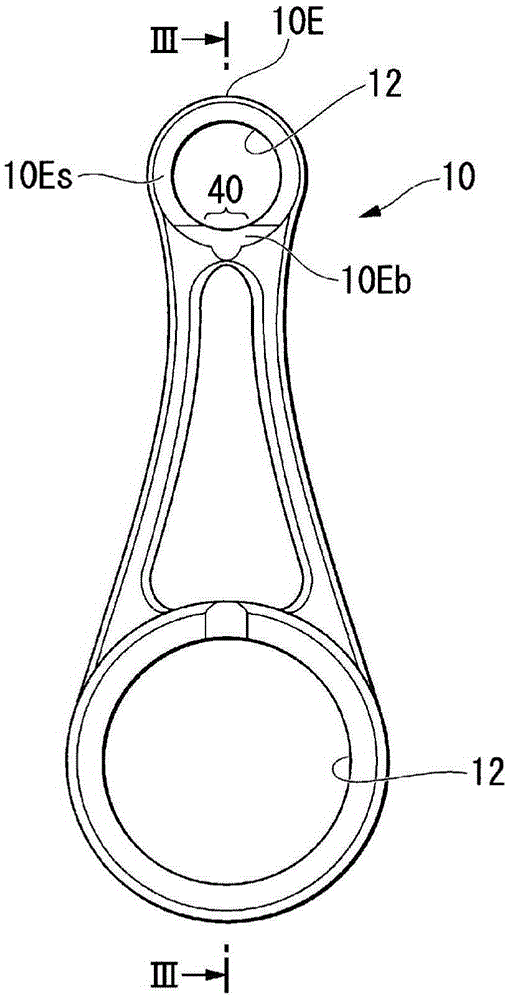

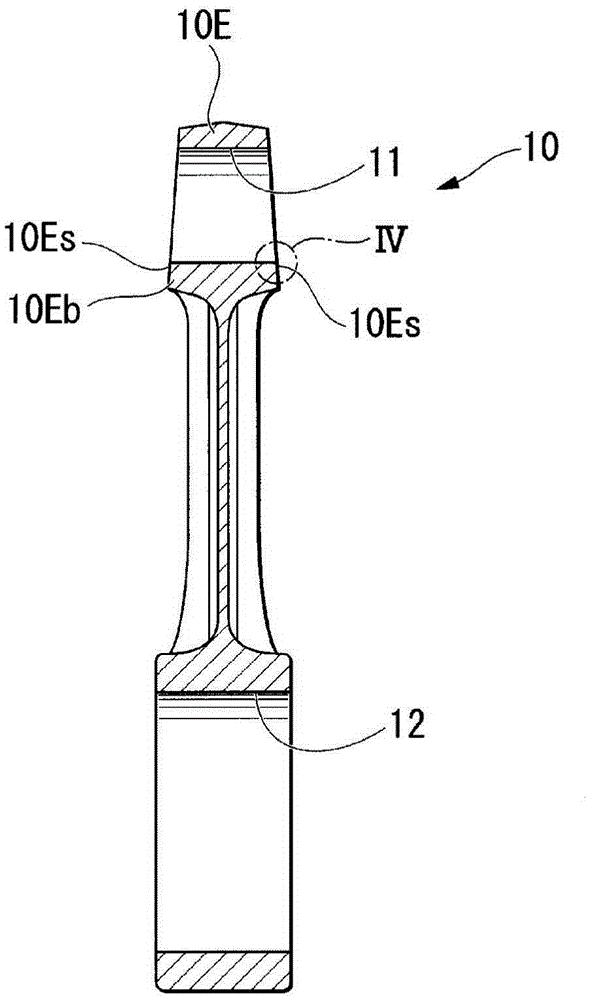

[0050] Hereinafter, one embodiment of the present invention will be described based on the drawings.

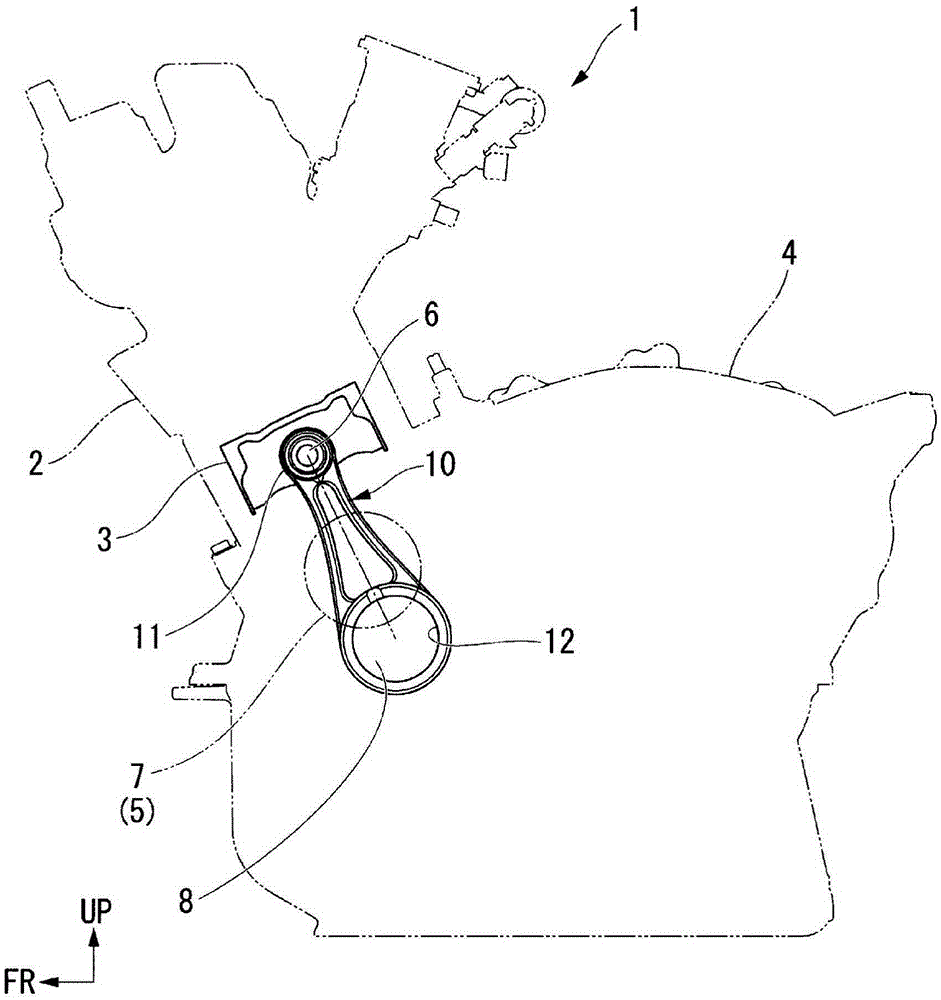

[0051] figure 1 It is a figure which schematically shows the internal combustion engine 1 which employs the connecting rod 10 of this embodiment. This internal combustion engine 1 is used in saddled vehicles such as motorcycles. In this figure, the arrow FR indicates the front when the vehicle is installed, and the arrow UP indicates the upper direction when the vehicle is installed.

[0052] Such as figure 1 As shown, a piston 3 is slidably accommodated in a cylinder portion 2 of an internal combustion engine 1 , and a crankshaft 5 is rotatably supported in a crankcase 4 below the cylinder portion 2 . A piston pin 6 extending radially is installed inside the piston 3 . A crank pin 8 is integrally provided on the crankshaft 5 so as to be eccentric to the rotation shaft 7 of the crankshaft 5 . In the case of the present embodiment, the piston pin 6 constitutes a power tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com