Pump device and vehicle

A pump device and pump part technology, which is applied to the pump device, the components of the pumping device for elastic fluid, the pump, etc., can solve the problems of poor wear resistance of the pump device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

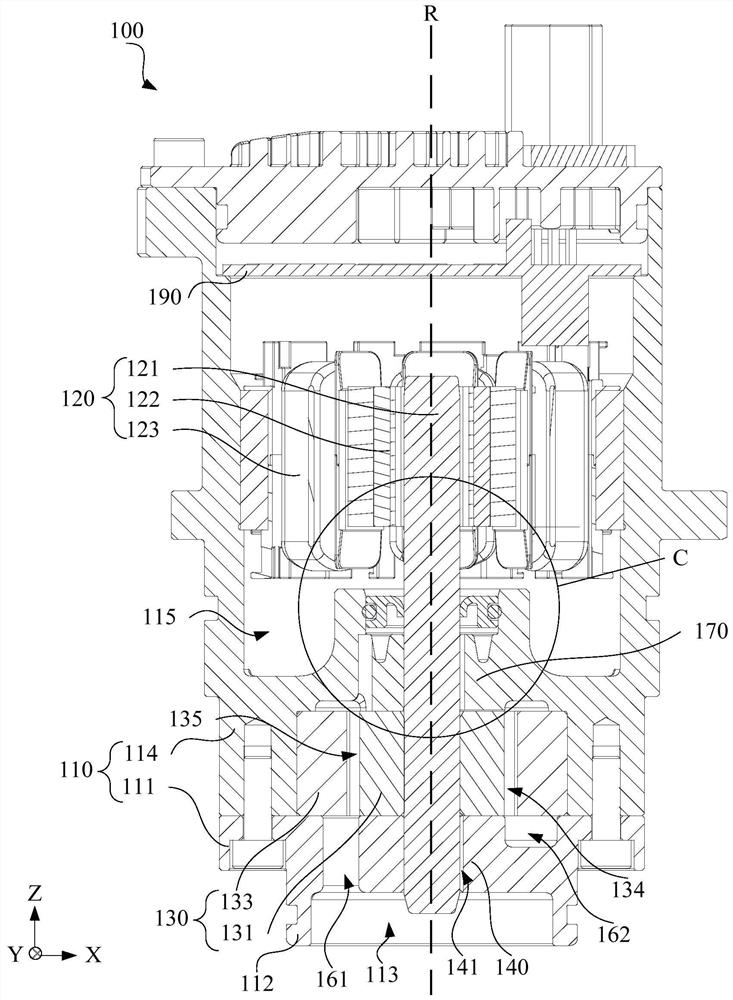

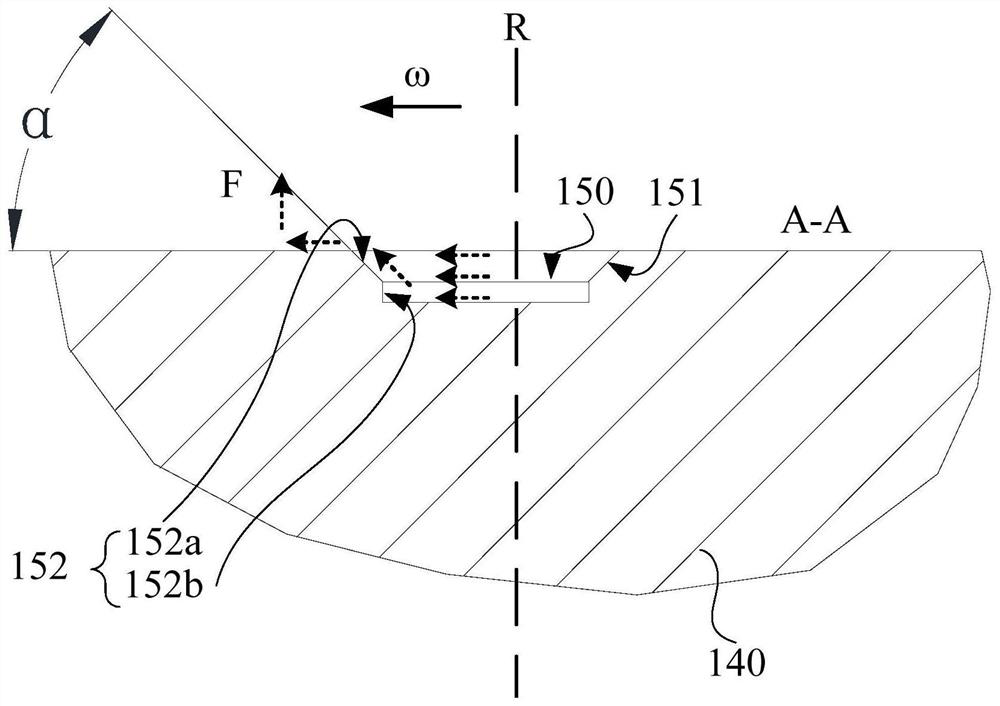

[0106] According to a first aspect of the present invention, a pump device 100 is provided, such as figure 1 and figure 2 As shown, it includes a housing 110 , a motor portion 120 , a pump portion 130 , a first bearing 140 and a thrust lubrication groove 150 . Wherein, the housing 110 has a cavity 115 . The motor part 120 is disposed in the cavity 115 , and the motor part 120 includes a rotating shaft 121 rotating around a central axis of the motor part 120 . The pump part 130 is disposed on one axial side of the motor part 120 and is in contact with the rotating shaft 121 , and the pump part 130 can be driven by the rotating shaft 121 to rotate. The first bearing 140 is connected with the casing 110 and sleeved on the rotating shaft 121 . The first bearing 140 is located on a side of the pump part 130 away from the motor part 120 . The thrust lubricating groove 150 is disposed on the end surface of the first bearing 140 close to the pump part 130 and communicates with the...

Embodiment 2

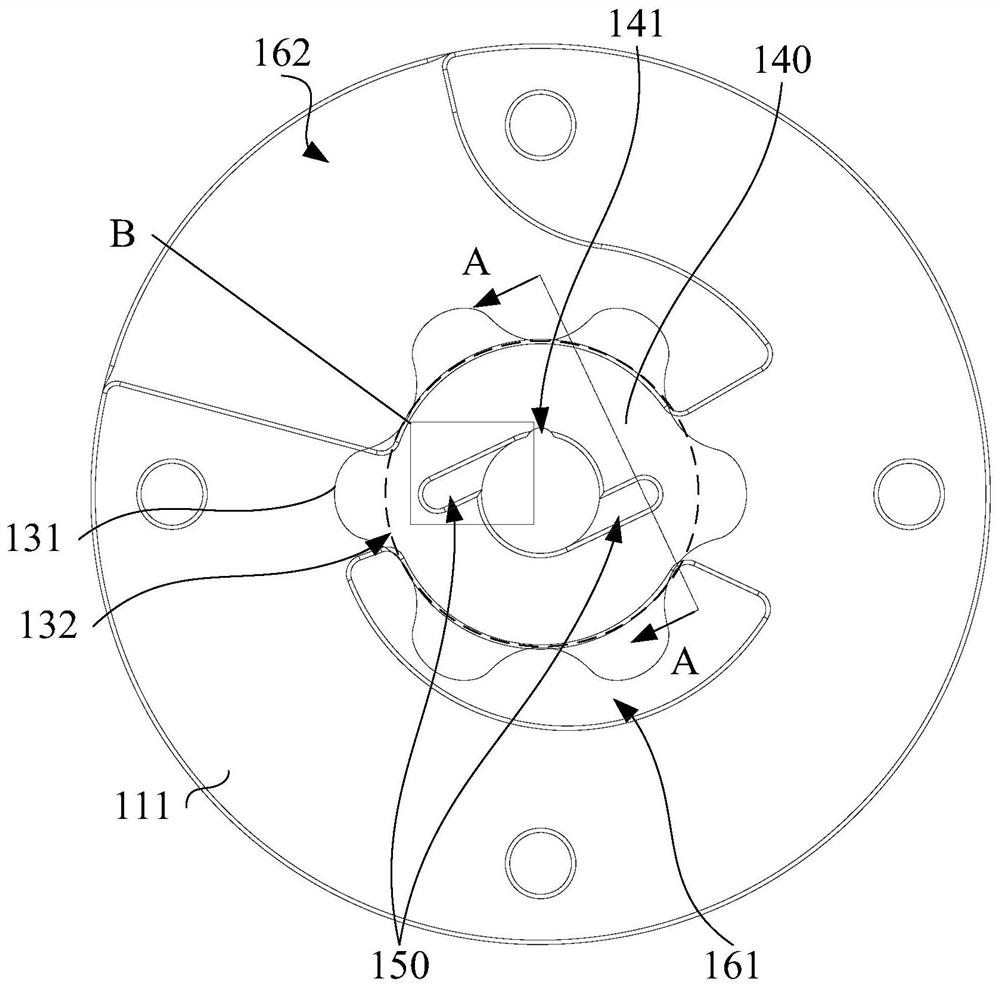

[0138] On the basis of Example 1, as figure 2 As shown, this embodiment explains the specific structure of the pump part 130. Further, the pump part 130 includes a first gear 131, the first gear 131 cooperates with the rotating shaft 121, and a plurality of dedendums of the first gear 131 form teeth The root circle 132 and the dedendum circle 132 extend axially to form an inner circular surface, and the thrust lubricating groove 150 is located in the inner circular surface.

[0139] In this embodiment, the pump part 130 includes a first gear 131 , the first gear 131 is in interference fit with the rotating shaft 121 , and the rotating shaft 121 rotates to drive the first gear 131 to rotate. A plurality of dedendums of the first gear 131 form a dedendum circle 132 . It should be noted that the dedendum circle 132 refers to a circle formed by the root of the tooth groove of the gear. The dedendum circle 132 extends axially to form an inner circular surface, and the thrust lub...

Embodiment 3

[0144] On the basis of the foregoing embodiments, the specific structure of the casing 110 is described in this embodiment. Further, the casing 110 includes a pump cover 111, and the pump cover 111 is arranged on the side of the pump part 130 away from the motor part 120. The pump The cover 111 is connected to the first bearing 140 .

[0145] In this embodiment, the casing 110 includes a pump cover 111 , the pump cover 111 is disposed on the side of the pump part 130 away from the motor part 120 , and the pump cover 111 is connected with the first bearing 140 . The first bearing 140 and the pump cover 111 can be detachably connected, of course, the first bearing 140 and the pump cover 111 can also be fixedly connected. Specifically, the first bearing 140 is integrated with the pump cover 111 , because the integrated structure has better mechanical properties, thereby improving the connection strength between the first bearing 140 and the pump cover 111 . In addition, the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com