A multi-tube energy-saving heat accumulator

A multi-tube, heat accumulator technology, applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of low heat exchange efficiency of low-flow materials, inability to control material temperature, and small heat storage To achieve the effect of improving heat storage capacity and cooling efficiency, increasing heat storage, and increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

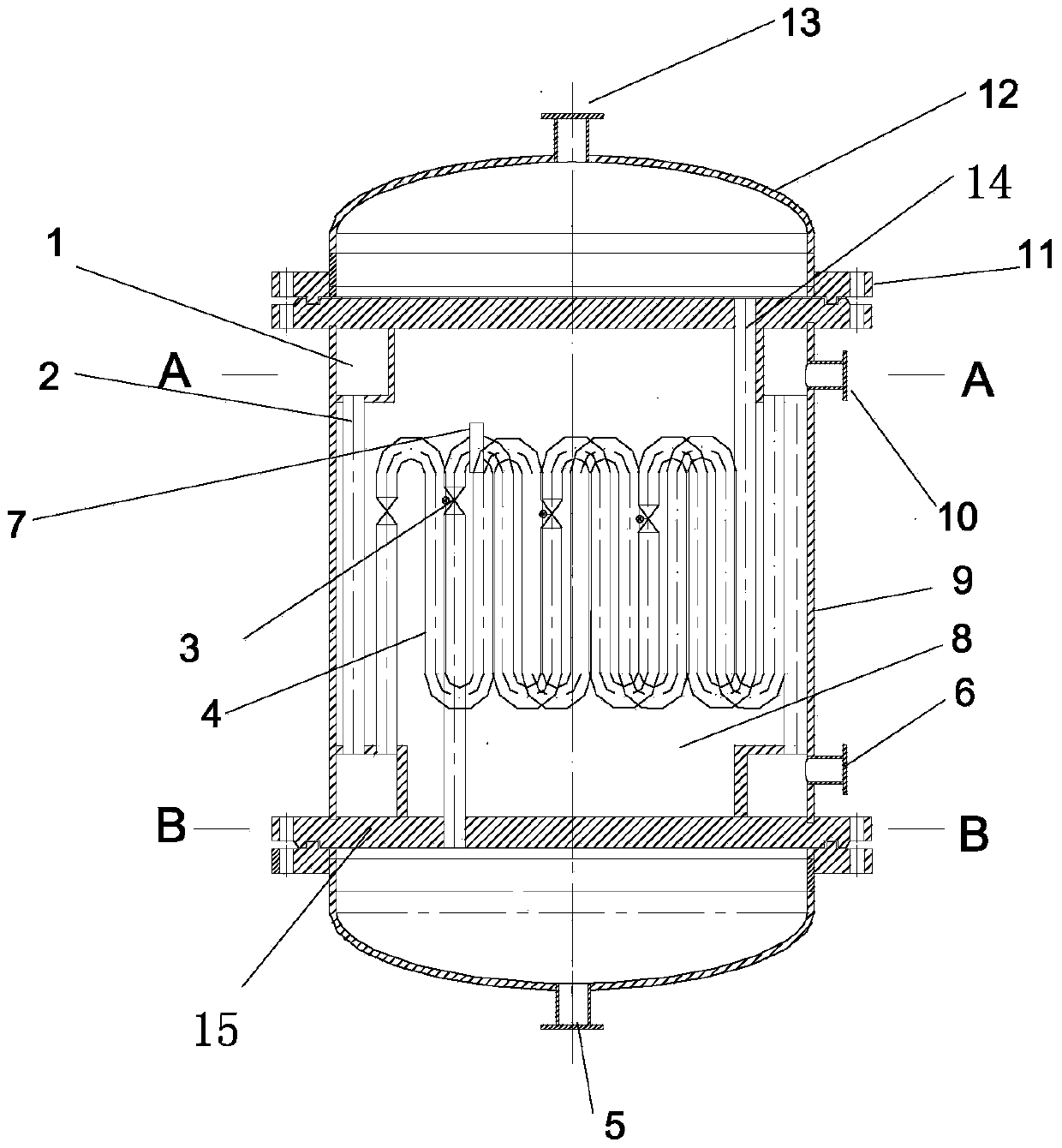

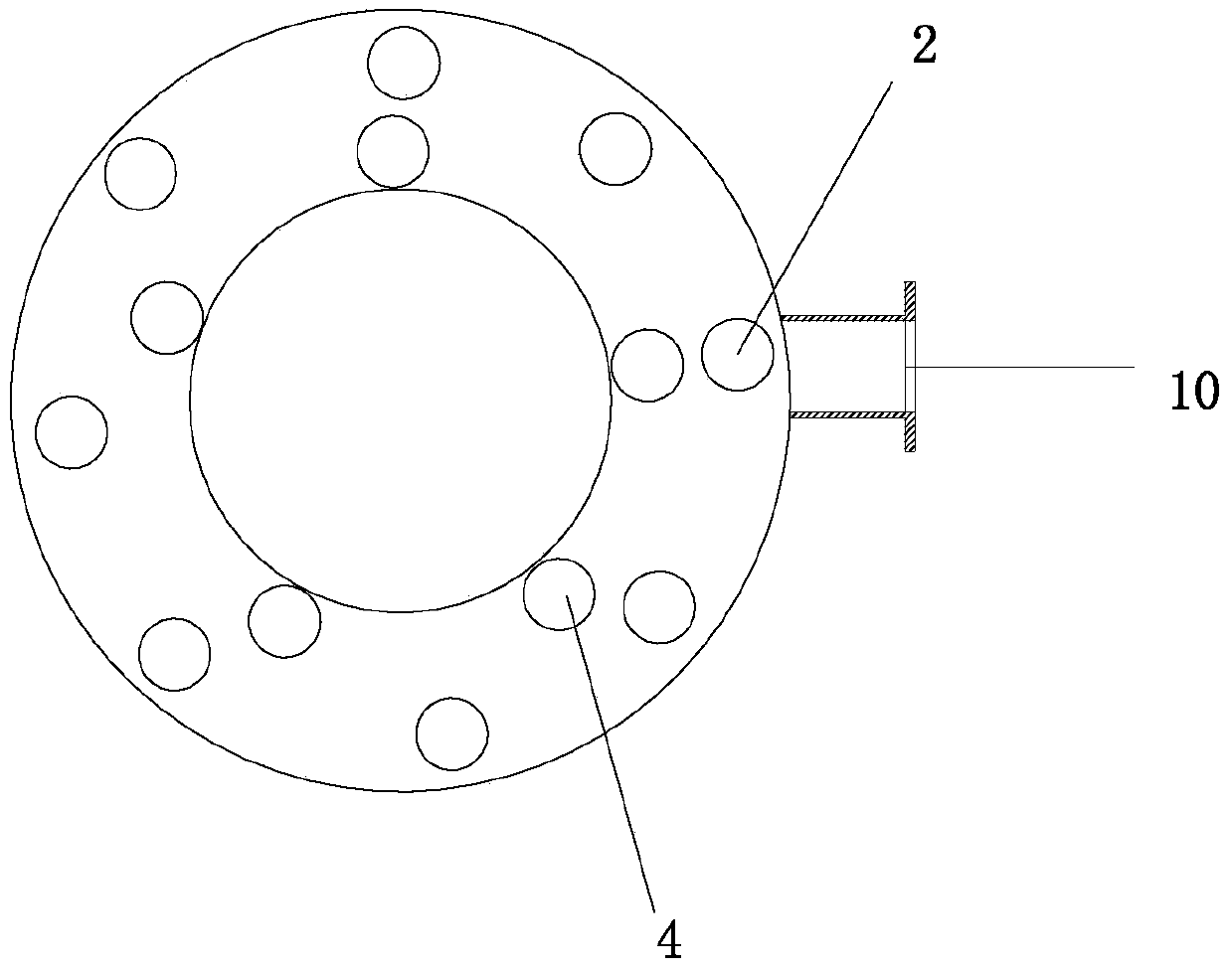

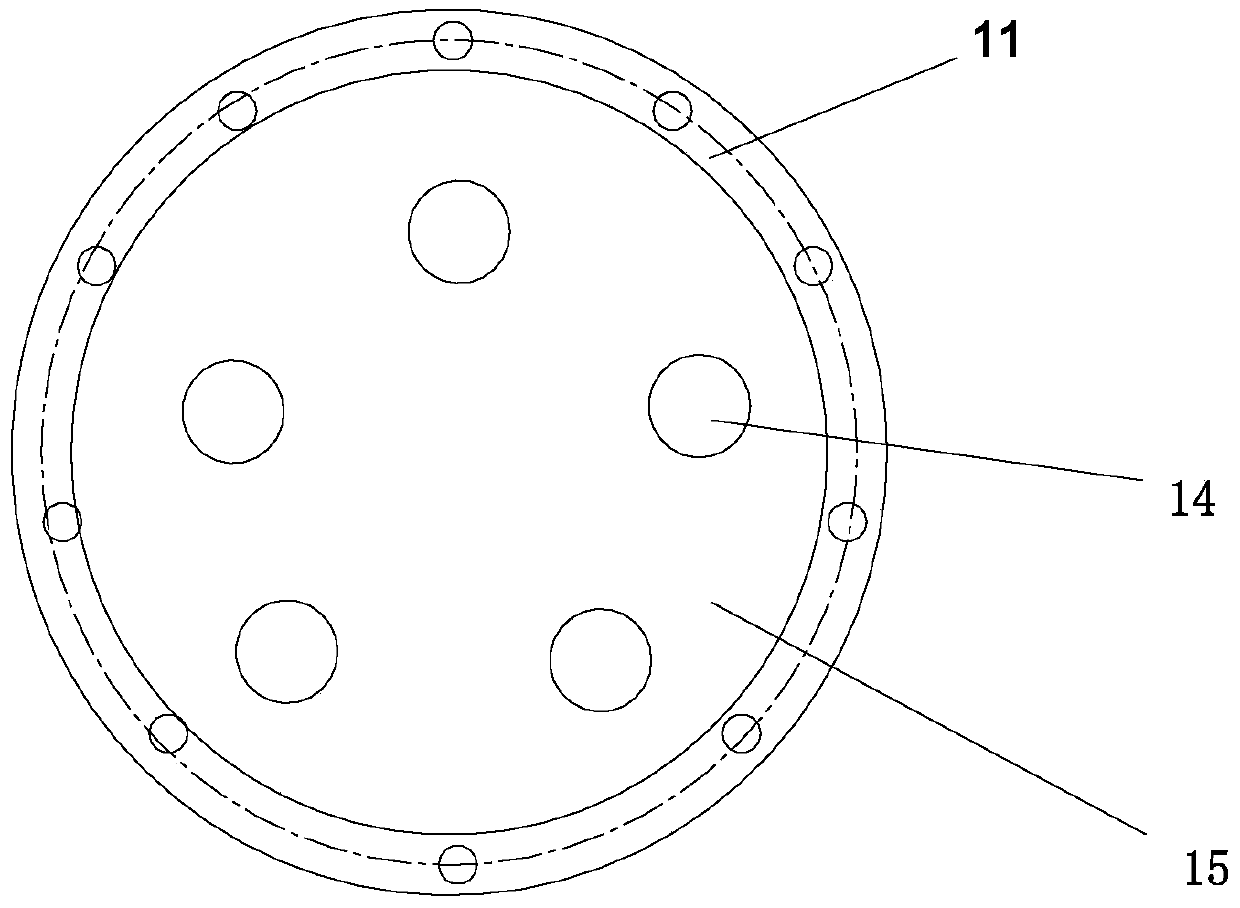

[0029] Such as Figure 1 to Figure 3 As shown, a multi-tube-pass energy-saving heat accumulator with cold and heat splitting includes a vertically arranged cylindrical cylinder 9, two hemispherical heads 12 connected to the upper and lower ends of the cylinder 9 through flanges 11, Between the upper and lower ends of the cylinder 9 and the two hemispherical heads 12, there is also a cylinder end plate 15 that isolates the inner cavity of the cylinder 9 from the inner cavity of the hemispherical heads 12, and is located at the upper end of the cylinder 9. The hemispherical head 12 is provided with a thermal fluid outlet 13, and the hemispherical head 12 located at the lower end of the cylinder 9 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com