Converging and supporting structure of dry electric reactor

A dry-type reactor and support structure technology, which is applied to the parts of transformer/inductor, transformer/inductor coil/winding/connection, circuit, etc., can solve the problem of large AC leakage magnetic field loss, overheating of support structure, low strength, etc. problems, to achieve the effect of ensuring safe operation, avoiding local overheating, and strong earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

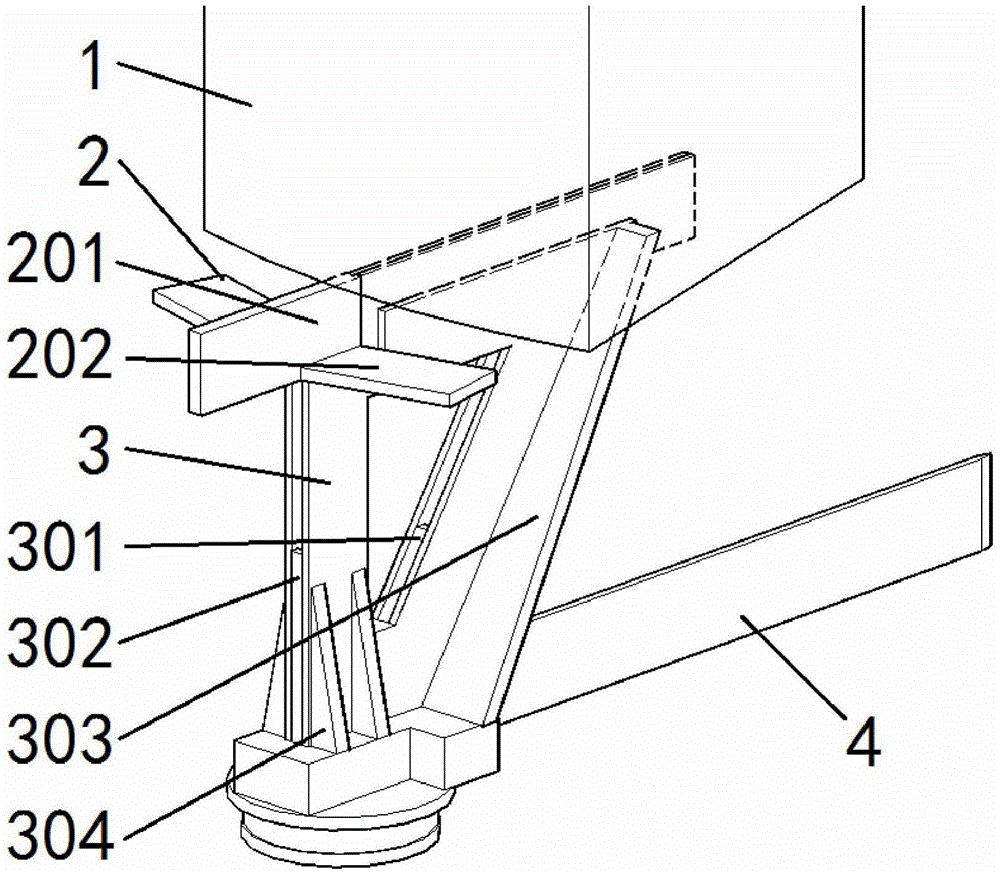

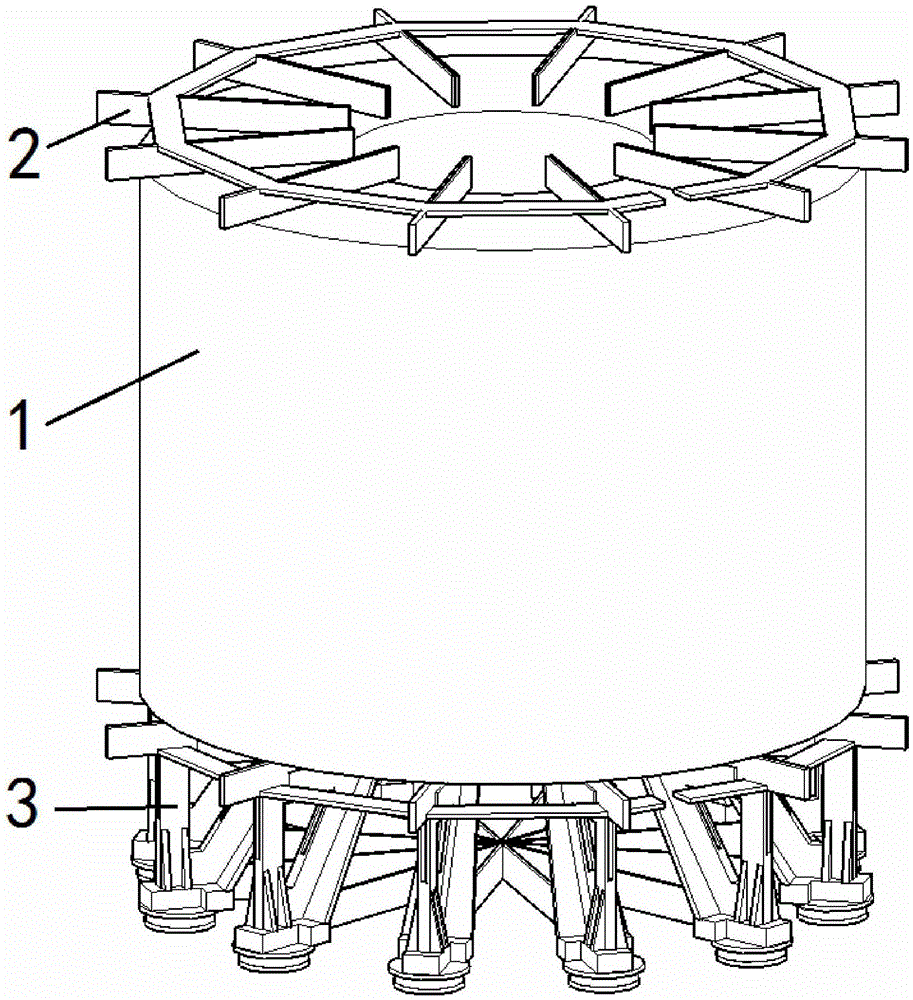

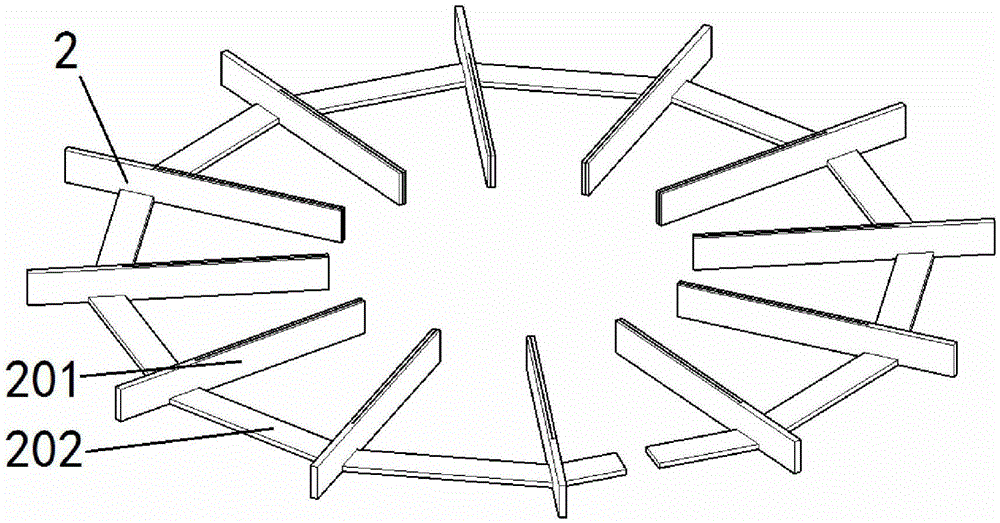

[0025] Such as Figure 1~3 As shown, the confluence and support structure of a dry-type reactor in the present invention includes a bus bar and a support frame. The bus bar 2 includes a vertical plate 201 and a connecting plate 202. The vertical plate is installed at the bottom of the reactor, and there are two connecting plates. Placed on both sides of the vertical plate, symmetrically arranged, multiple bus bars with the same above-mentioned structure are arrayed along the upper and lower parts of the dry-type reactor coil along the coil circumference, and the adjacent bus bar connecting plates are electrically connected in turn, leaving a non-electrical Connection position: the upper part of the supporting structure is provided with a notch, and the busbar installed at the lower part of the coil is installed in the notch of the supporting structure, and the supporting structure is arrayed along the circumference of the coil, corresponding to the busbar.

[0026] Such as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com