Accumulator plate packaging machine and pole plate feed mechanism thereof

A technology of plate-cladding machine and battery, applied in lead-acid battery electrodes, lead-acid battery, lead-acid battery construction and other directions, can solve the problems of cylinder leakage, easy to be corroded, dusty, etc., to protect the sealing ring, the service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present application provides a plate feeding mechanism for a battery packer.

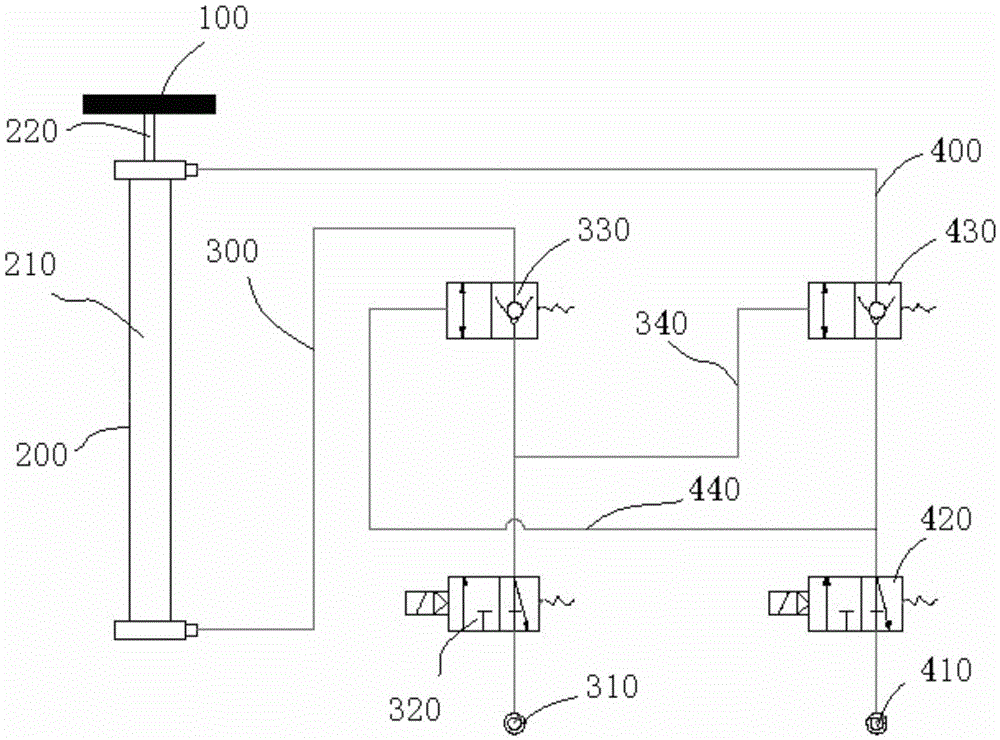

[0025] Please refer to figure 1 , the plate feeding mechanism includes a support plate 100 , a cylinder 200 , an ascending air path 300 and a descending air path 400 .

[0026] Wherein, the cylinder 200 has a cylinder body 210 and a piston 220, the piston 220 divides the cavity of the cylinder 200 into an upper cavity and a lower cavity (not shown in the figure), and one end of the piston 220 is connected with the support plate 100 to drive the support plate 100 rises and falls.

[0027] The ascending air passage 300 communicates with the lower chamber of the cylinder 200 to control the ascending of the piston 220 . The descending air passage 400 communicates with the upper chamber of the cylinder 200 to control the descending of the piston 220 .

[0028] This application uses air pressure control instead of gas-liquid mixing control to prevent the cylinder 200 from working in a humid ...

Embodiment 2

[0048] The second embodiment provides a battery wrapping machine, which includes a plate feeding mechanism, the function of which is mainly to control the positioning of the gap between the plates and convey them upward.

[0049] Wherein, the pole plate feeding mechanism adopts the structure shown in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com