Engine cylinder upper stop point positioning device and positioning method

An engine cylinder and positioning device technology, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of difficulty in measuring multi-cylinder engines, complex structure, high cost, low positioning efficiency, etc., and achieves convenient measurement of multi-cylinder engines and simple structure. Low cost and high positioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

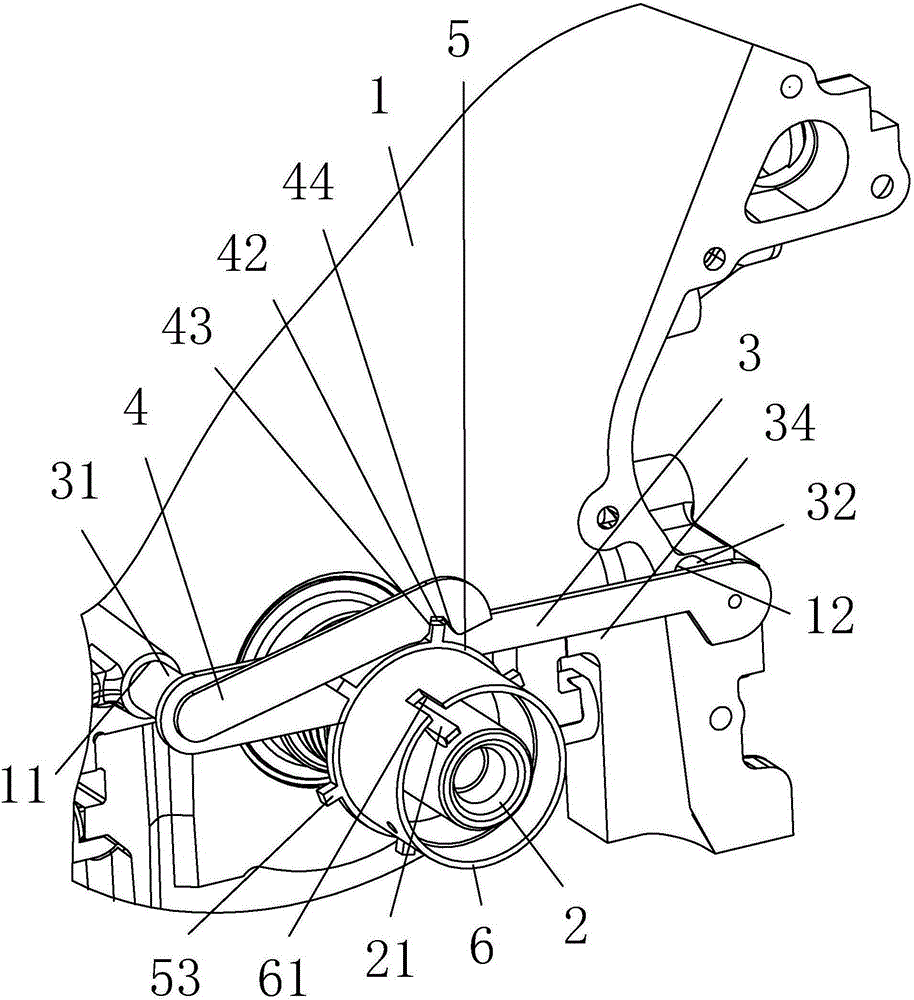

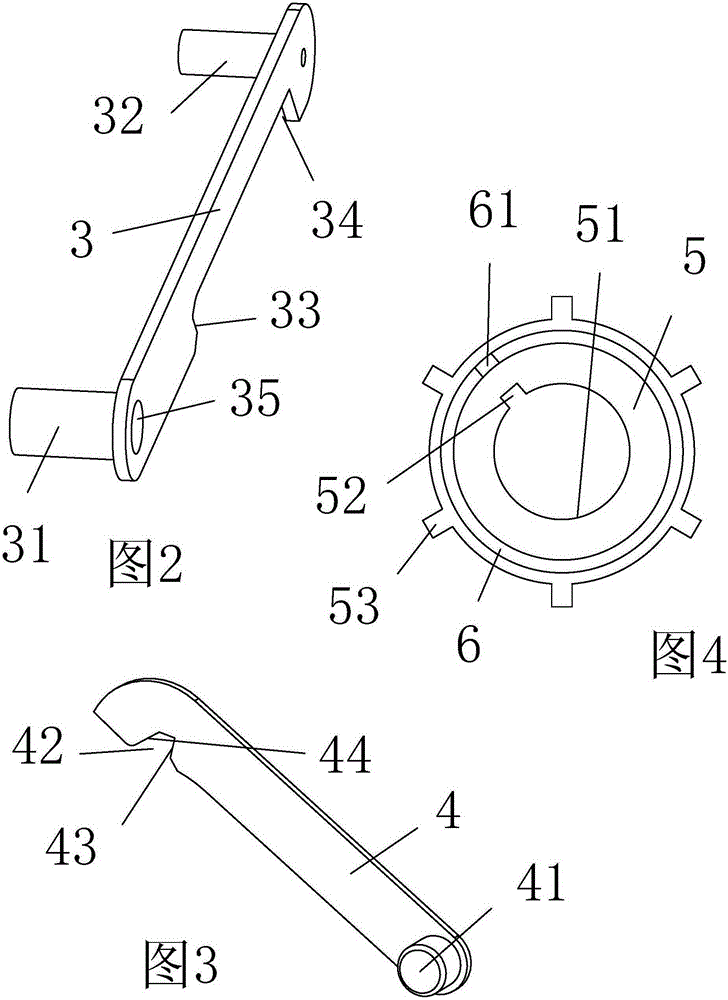

[0016] as attached figure 1 to attach Figure 4 Shown: a positioning device for the top dead center of an engine cylinder, including a cylinder block 1 of an engine with a first positioning hole 11 and a second positioning hole 12 at one end, and a crankshaft with a connecting key 21 at one end and protruding from one end of the cylinder block 1 2. One side is provided with the positioning rod 3 of the first positioning shaft 31 which is in clearance fit with the first positioning hole 11 and the second positioning shaft 32 is in clearance fit with the second positioning hole 12, and one end is provided with the other side of the positioning rod 3 A hinged shaft 41 hinged at one end and a one-way thrust rod 4 whose rotation axis is parallel to the axis of the crankshaft 2 of the engine is provided with an inner hole 51 that is loosely fitted with the crankshaft 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com