Automatic areca nut sectioning device

A betel nut and automatic technology, applied in metal processing, etc., can solve the problems of high scrap rate, increased production cost of enterprises, and inability to realize cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

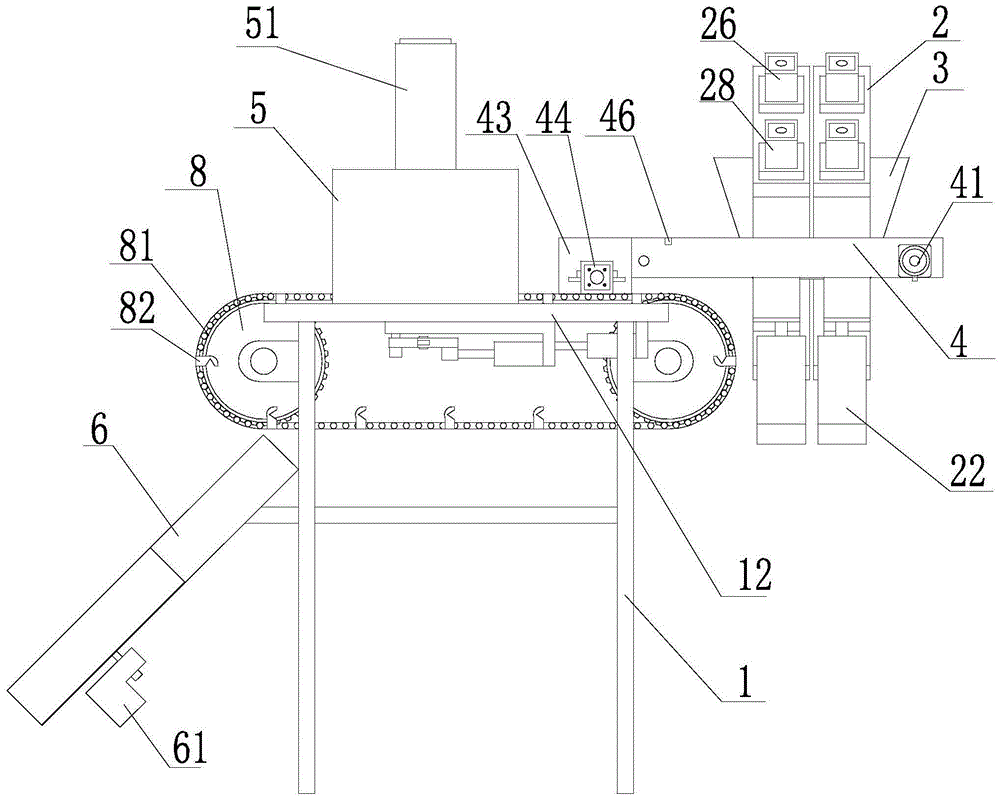

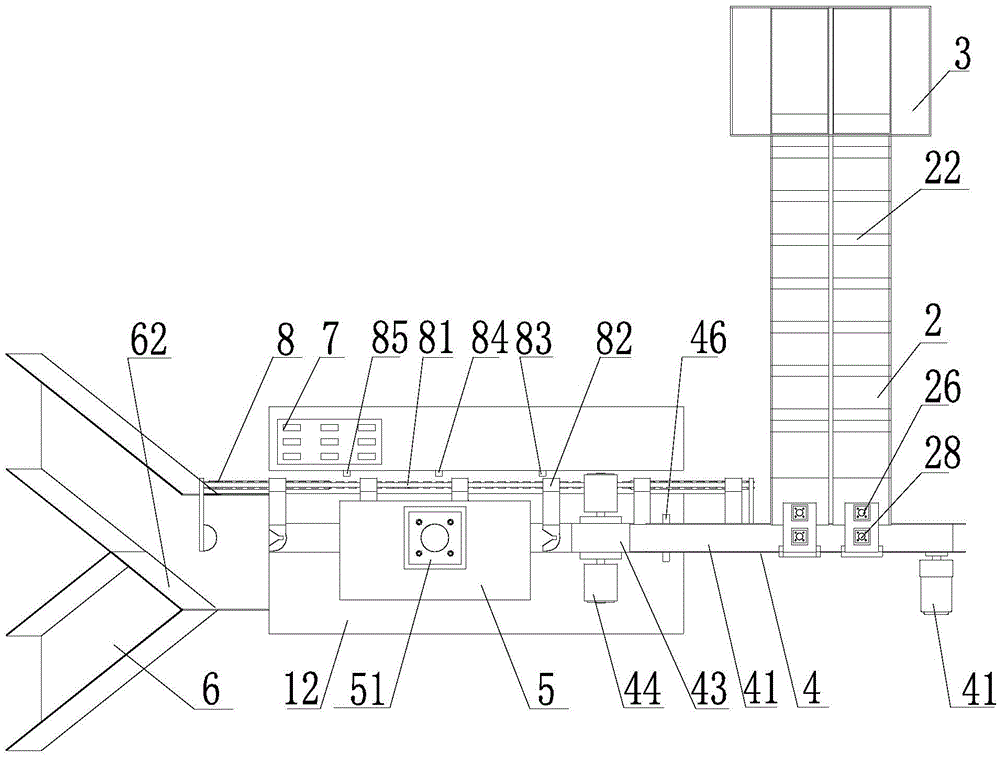

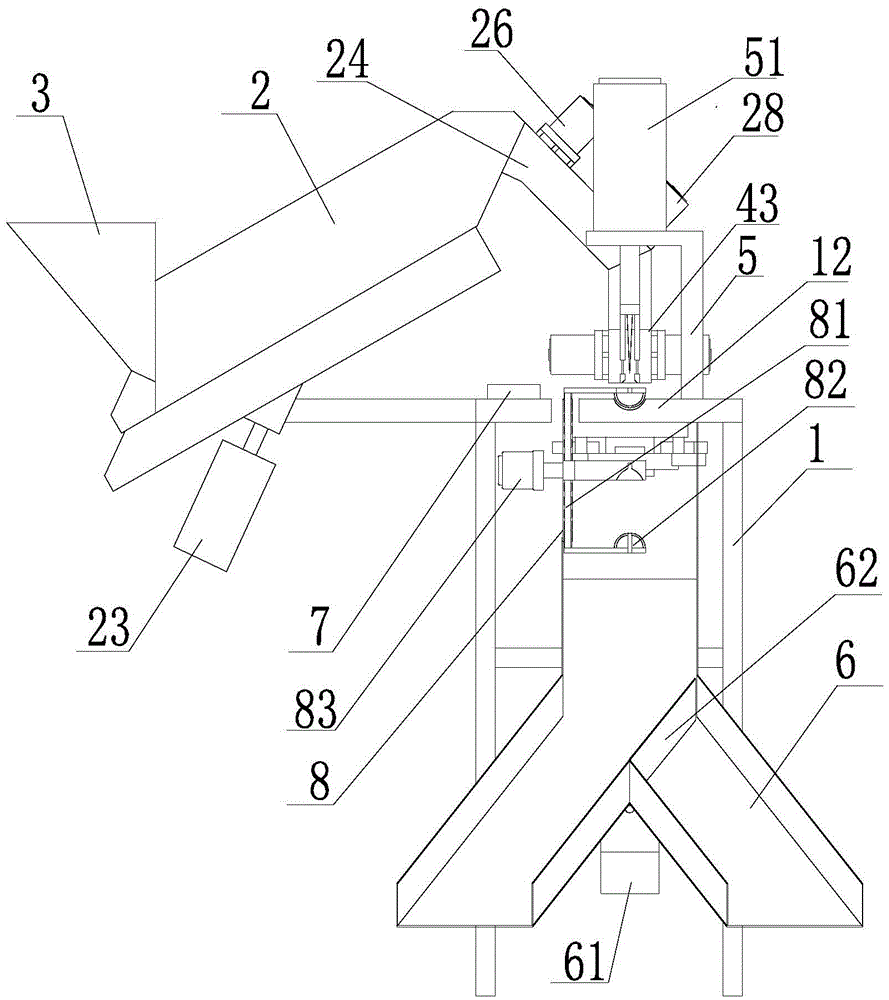

[0029] Such as figure 1 , figure 2 , image 3 Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 Shown, 1: a kind of betel nut automatic cutting device, on frame 1, cascade queuing feeding device, feeding device, cutting device, electrical control system are housed; Material device, the feeding device is connected to the cutting device, and the cutting device is connected to the finished product sorting groove 6;

[0030] The step queuing feeding device includes a step groove 2, the step groove 2 is installed on the frame 1, the bottom of the step groove 2 is a step 21 with a through hole, and the comb-toothed push rod 22 is inserted into the step 21 with a through hole. In the through hole, a sparse-toothed ejector pin push cylinder 23 is installed on the bottom surface of the comb-toothed ejector pin 22, and the comb-toothed ejector pin push cylinder 23 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com