Saw blade separation device for band sawing machine

A partition device and band saw machine technology, applied in band saws, sawing equipment, wood processing equipment, etc., can solve the problems of high processing cost, poor board quality, long processing time, etc., achieve long service life and wide application range , The effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

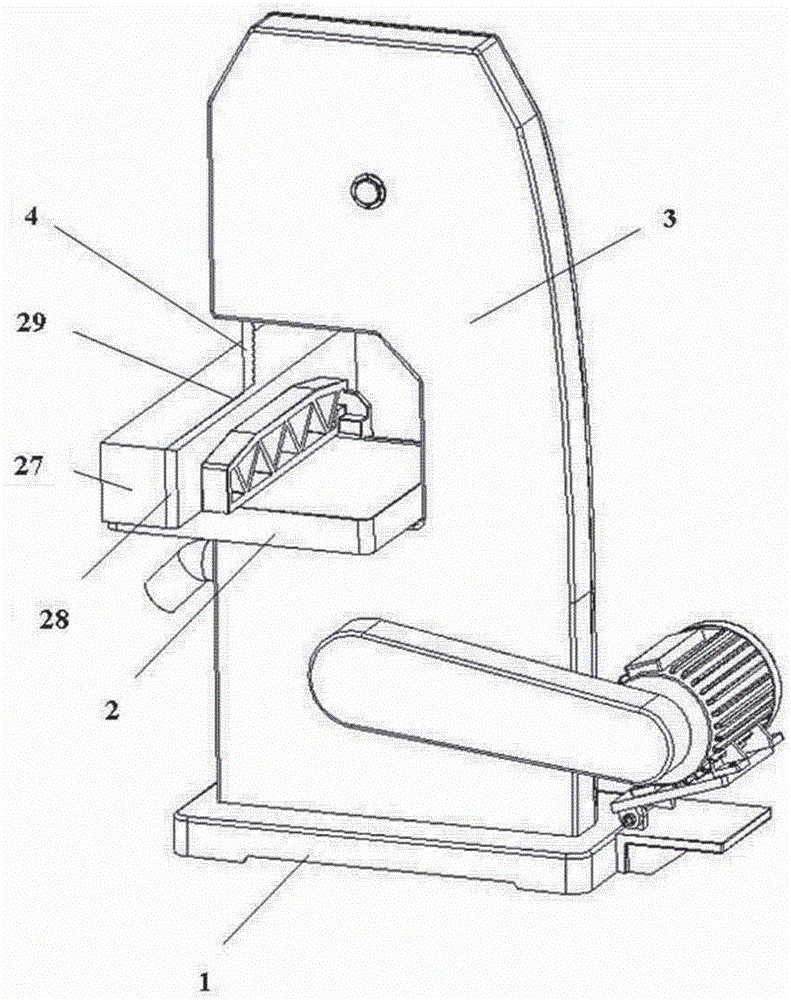

[0046] Use saw blade spacer of the present invention on vertical band saw machine (referring to Figure 4-6 ), the workbench and the sawing device are perpendicular to each other, the separator is arranged behind the saw blade, and a wedge-shaped knife edge 25 is provided near the side of the saw blade. The separator and the saw blade are aligned and arranged on the same vertical plane. The separator The two ends of the separator are connected with the shell of the sawing device, and one end of the separator is fixedly connected with the first fixing device through the first fastening adjusting bolt 15 arranged in the first connecting hole, and the other end of the separator is connected with the second fixing device. The device forms a movable and adjustable connection through the first fastening and adjusting bolt 15 arranged in the second connection hole 12. One side of the second tensioning and fixing device is provided with a tensioning device. The tensioning device consis...

Embodiment 2

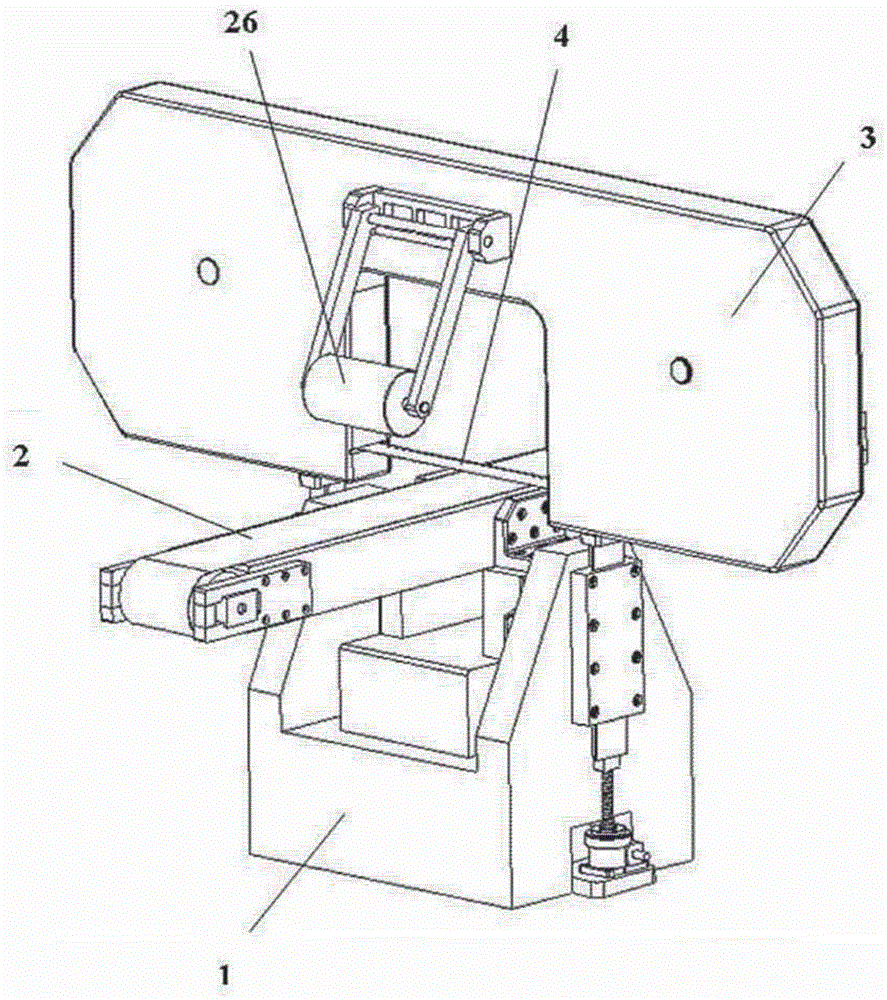

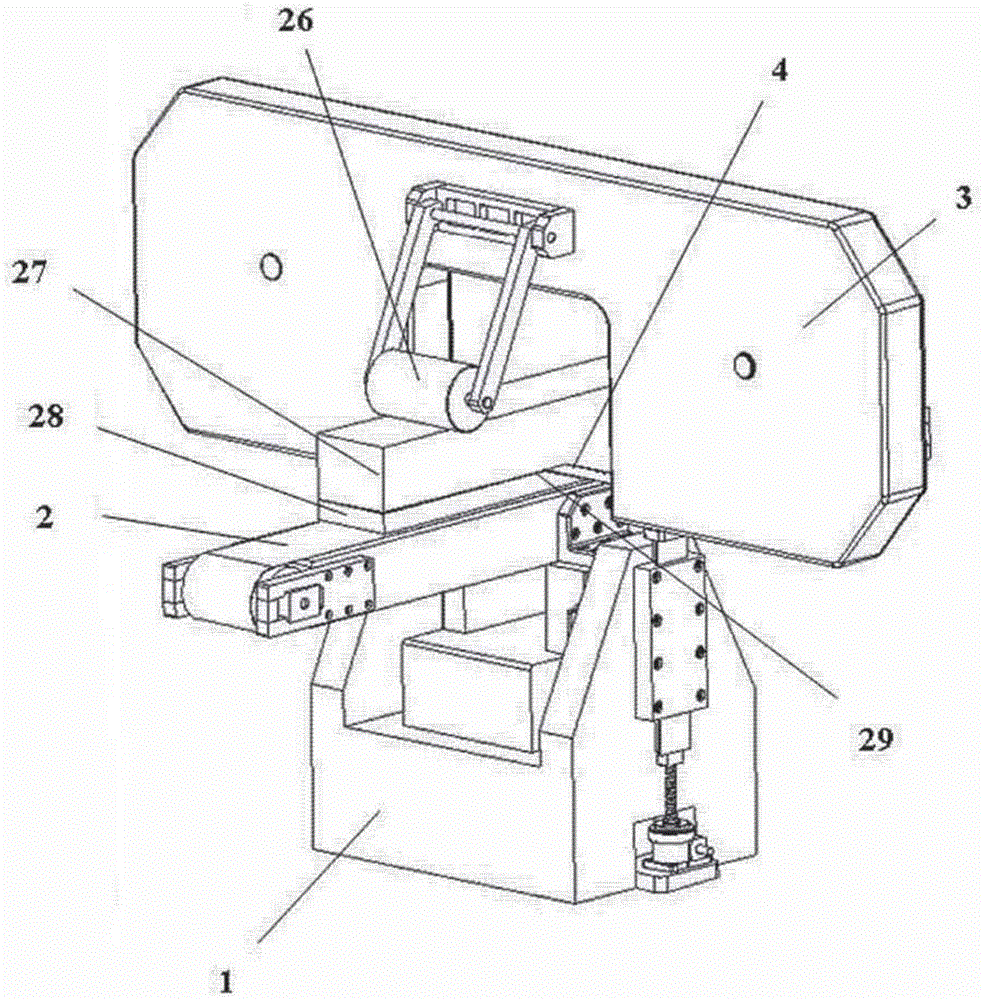

[0049] Use the saw blade spacer of the present invention on a horizontal band saw machine (see Figure 7-10 ), the workbench and the sawing device are parallel to each other, the separator is arranged behind the saw blade, and a wedge-shaped knife edge 25 is provided near the side of the saw blade. The separator and the saw blade are arranged on the same horizontal plane, and the two ends of the separator The shell of the device is connected, and one end of the separator is fixedly connected with the first fixing device through the first fastening adjustment bolt 15 arranged in the first connection hole, and the other end of the separator is provided with a group of elongated adjustment holes 11, separating The other end of the sheet and the second fixing device form a movably adjustable connection through the first fastening adjustment bolt 15 arranged in the second connection hole 12, and the tension degree and effective working length of the entire partition board are determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com