Stirring machine for grouting hole sealing

A mixer and hole sealing technology, which is used in cement mixing devices, sealing/sealing, clay preparation devices, etc., can solve problems such as affecting the enthusiasm of the staff, aggravating the labor intensity of the staff, affecting the work progress, etc., so as to facilitate cleaning and maintenance. , the effect of reducing labor intensity and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

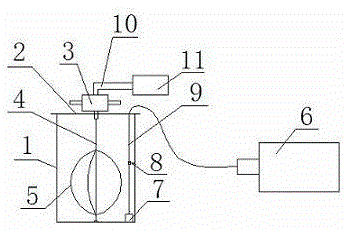

[0019] figure 1 Show a specific embodiment of a mixer for grouting and sealing of the present invention: the mixer for grouting and sealing includes a mixer body, the mixer body includes a mixing tank 1 with an upper opening, and the upper opening of the mixing tank 1 is convenient for the staff to seal the hole The mud is poured into the mixing tank 1, which improves the work efficiency; the upper opening of the mixing tank 1 is detachably connected with a support frame 2, and the support frame 2 can not only prevent debris from falling into the sealing mud of the mixing tank 1, but also ensure The mud quality is also convenient to carry the pneumatic drilling rig 3 in the driving device, which ensures the stability in use and improves the safety; the middle part of the lower surface of the inner wall of the mixing tank 1 is vertically connected with a stirring axis with one end protruding from the support frame 2 4. A stirrer 5 is sleeved on the side wall of the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com