Optical anti-counterfeiting element and optical anti-counterfeiting product using optical anti-counterfeiting element

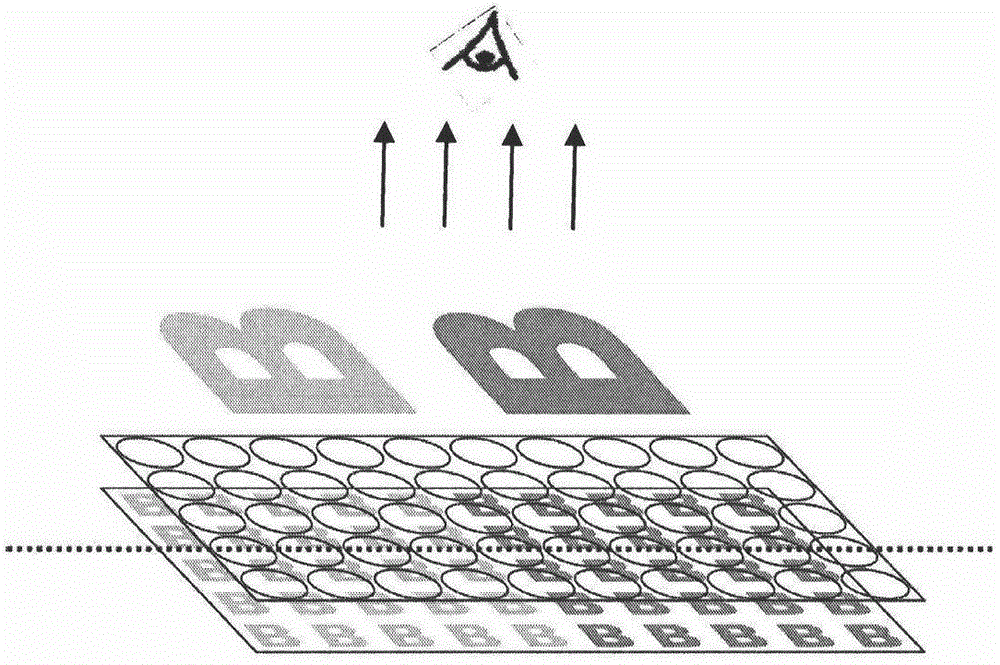

An optical anti-counterfeiting and component technology, which is applied to patterns, prints, special patterns, etc. characterized by light projection effects, can solve the problems that the structure cannot be colored, and the plane covering method is difficult to achieve, and achieves strong public attraction. Easy-to-recognize and process-feasible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

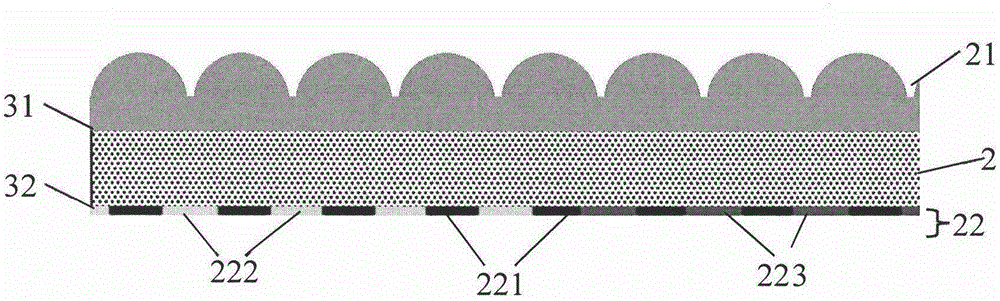

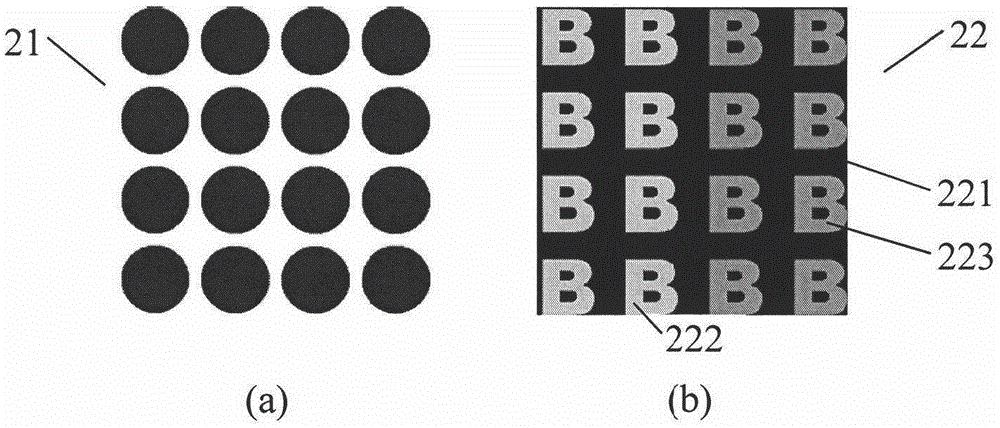

[0038] figure 2 The preparation method shown is to prepare Figure 1a The optical security elements shown are targeted. First, prepare the sampling composite layer 21 on the first surface 31 of the substrate 2 and prepare the sinusoidal one-Via wavelength grating structure 41 on the second region on the second surface 32 of the substrate 2, the period of the grating structure is 245 nm and a depth of 150 nm, the first region on the second surface 32 is a flat region. Then, on the second surface 32 of the substrate 2, directly deposit an Al layer with a thickness of 60nm (with the thickness on the first region as a reference), and then deposit a thickness of 50nm on the Al layer (with a thickness on the first region of Reference) Si, then the whole structure is placed in NaOH solution (temperature 40 ℃, concentration 5%) and soaked for 18 seconds, then the Si layer and Al layer formed on the second area disappear completely successively, and the Al layer formed on the first a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com