Connecting sleeve assembly of vibration absorber

A technology for connecting sleeves and shock absorbers, which is applied to vehicle components, elastic suspensions, suspensions, etc., can solve the problems of low processing difficulty and high overall structural strength, and achieve simple processing technology, enhanced structural strength, and enhanced structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

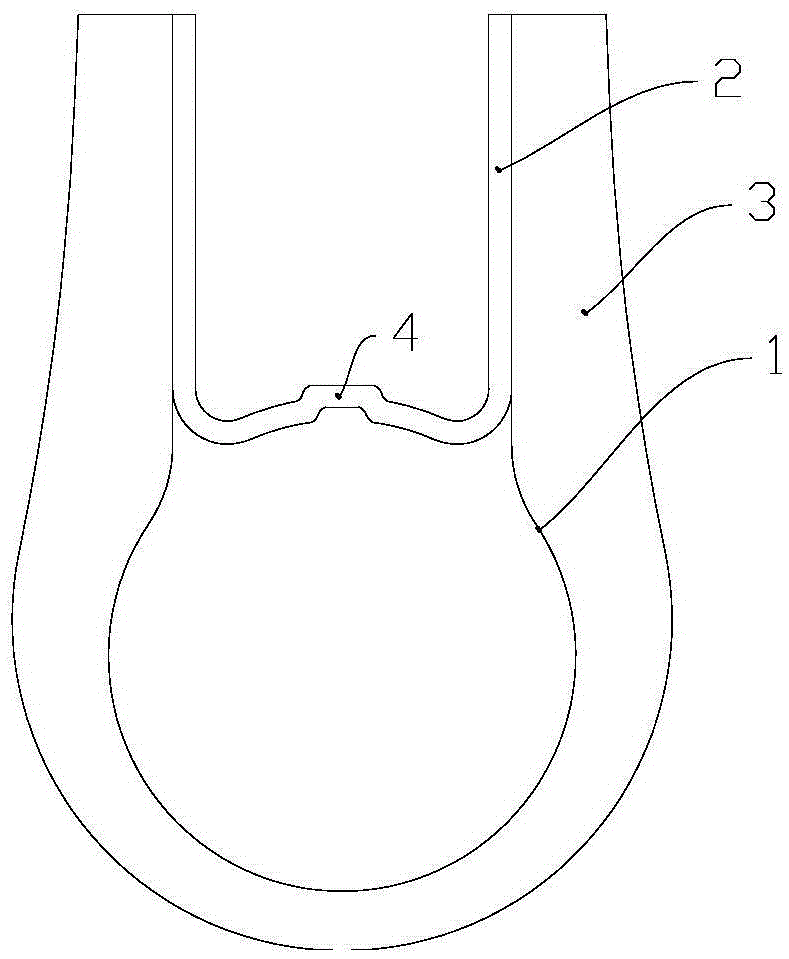

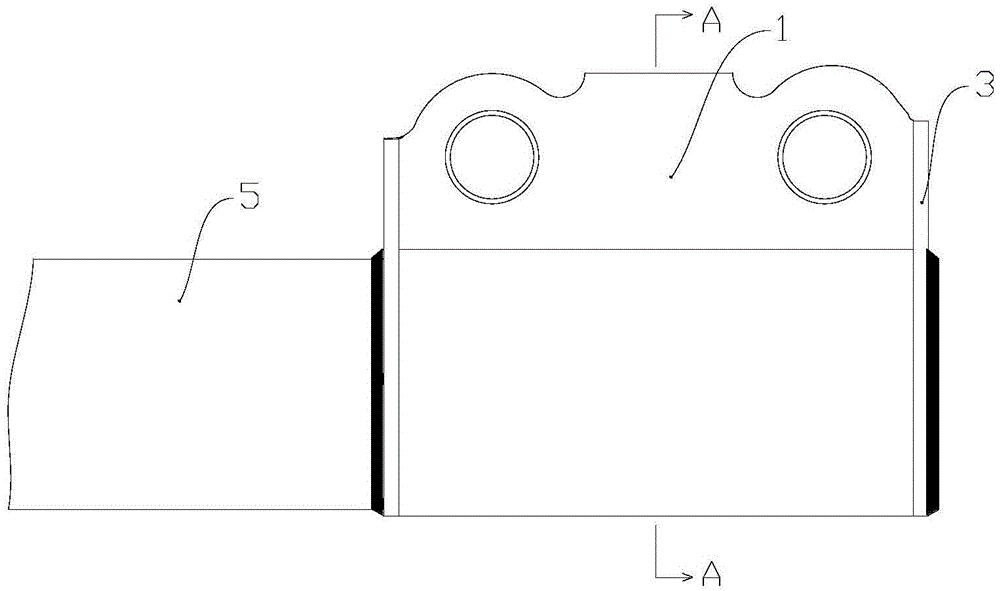

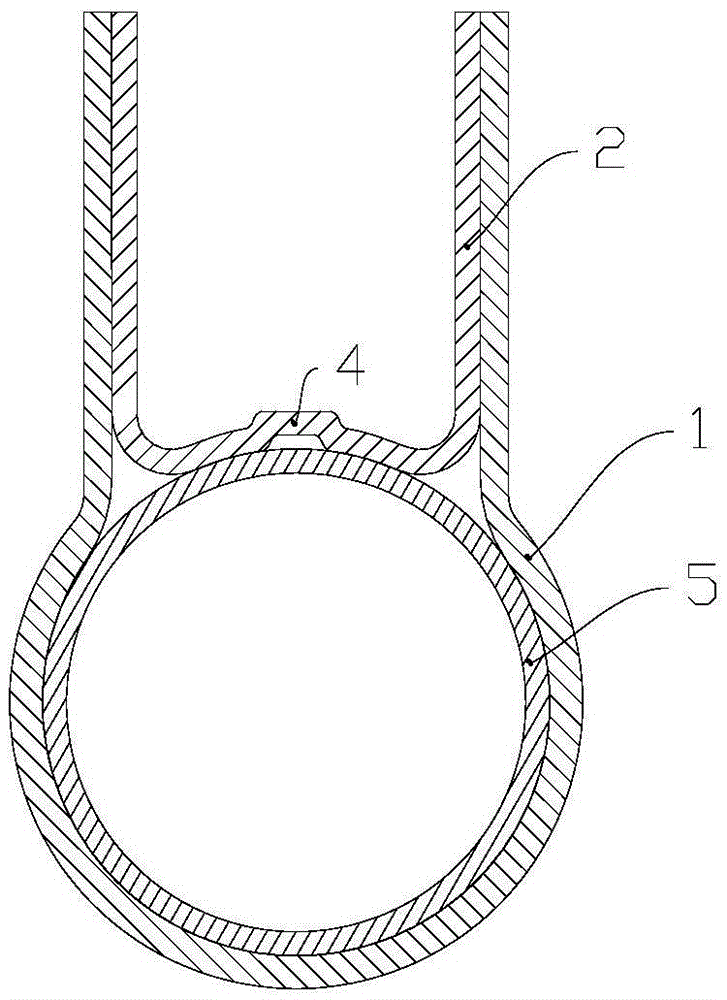

[0013] Such as figure 1 As shown, it is a shock absorber connecting sleeve assembly, which includes a connecting sleeve 1 with a U-shaped cross-section. The two ends of the connecting sleeve 1 are respectively provided with reinforcing skirts 3, and the reinforcing skirt 3 and the connecting sleeve 1 are of an integral structure. The reinforced skirt 3 extends outward along the end surface of the connecting sleeve 1, and is vertically outwardly flanging with the connecting sleeve 1, and the connection between the reinforced skirt 3 and the connecting sleeve 1 adopts a circular arc transition; A connecting plate 2 is provided at the opening, and the connecting plate 2 is fixedly connected with the connecting sleeve 1. The connecting plate 2 is used for fixedly connecting the opening end of the connecting sleeve 1, and plays a role of connecting and reinforcing the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com