Turnover lifting tool

A spreader and rigging technology, which is applied in the field of turning spreaders, can solve the problems of long time and difficult lifting, and achieve the effects of prolonged life, convenient and quick disassembly, and increased bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

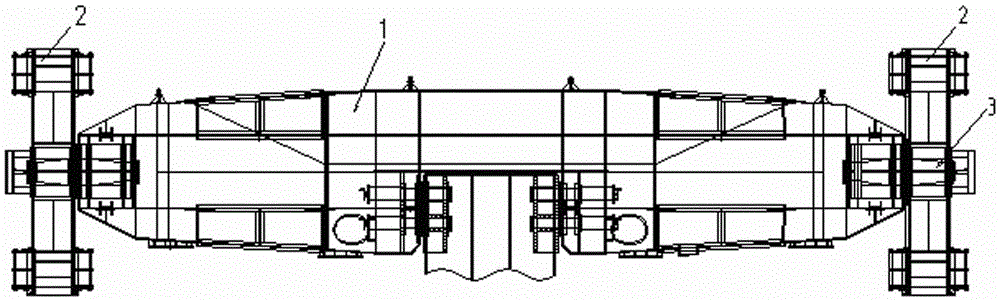

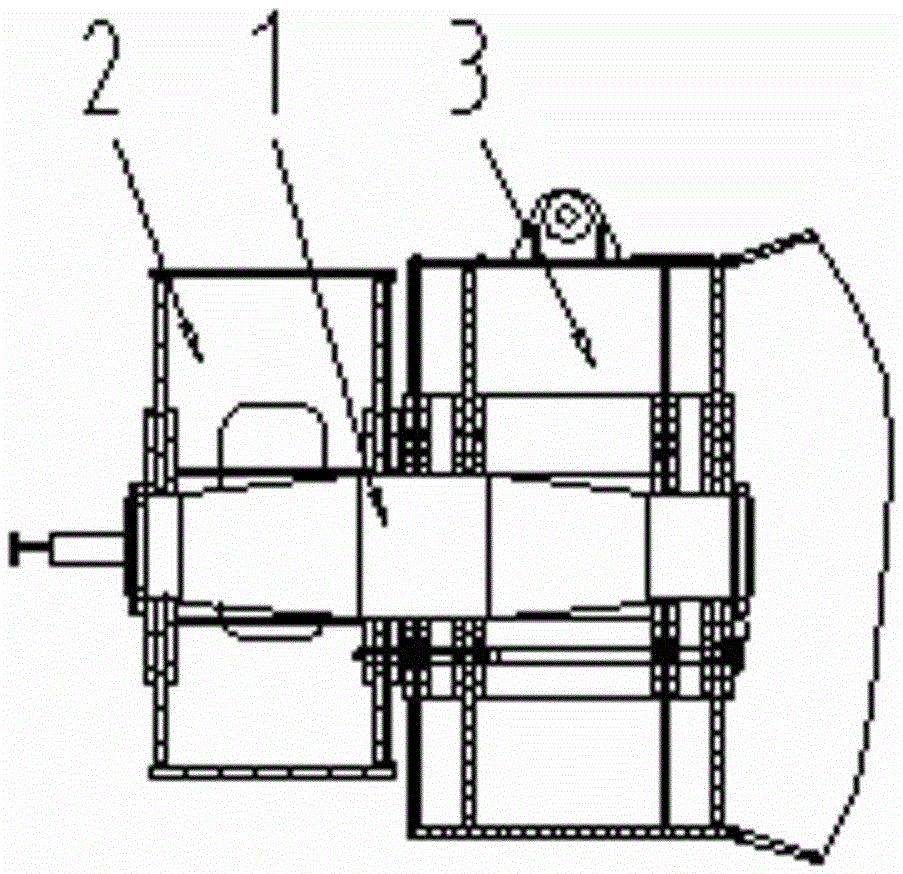

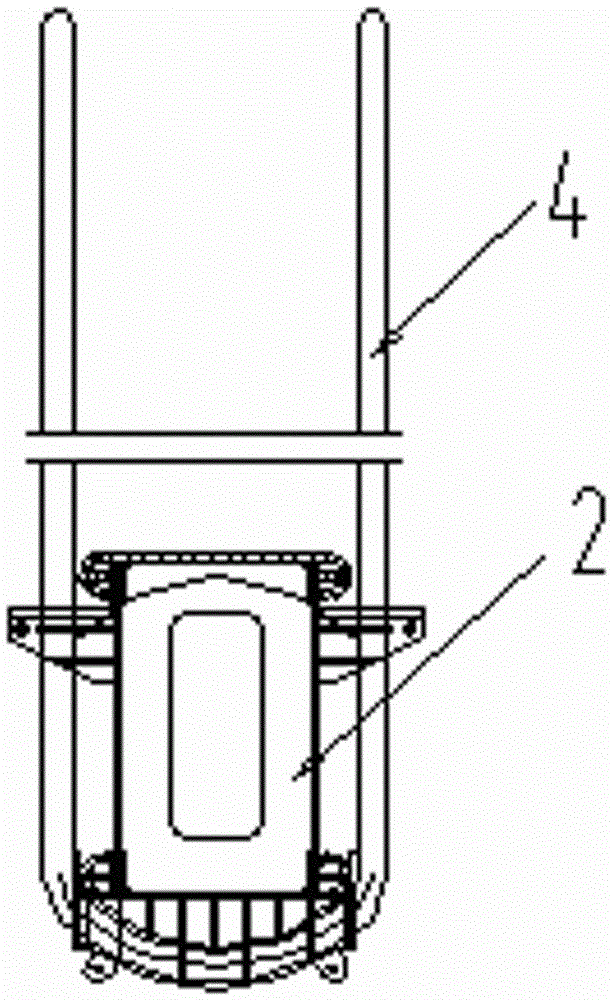

[0024] Such as Figure 1~5 As shown, a turning hanger includes a main beam 1 and a balance beam 2, the two ends of the main beam 1 are equipped with the balance beam 2, and the main beam 1 and the balance beam 2 are connected by a connecting shaft 3, The balance beam 2 rotates 360° with the axis of the connecting shaft 3 as the axis, and the two ends of the balance beam 2 are connected with the crane hook 8 through the rigging 4; when turning over, the main beam 1 is installed On the main tower 7, the middle part of the main beam 1 is connected with the main tower 7, and the main beam 1 and the main tower 7 rotate relative to the balance beam 2 at the same time to realize the turning of the main tower.

[0025] Such as Figure 4 As shown, the outside of the connecting end of the balance beam 2 and the connecting shaft 3 is provided with a cylinder support 6, and a hydraulic device 5 for dismounting the balance beam is provided between the cylinder support 6 and the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com