A method for removing green oil film in waste circuit boards

A waste circuit board and green oil film technology, which is applied in the field of removing green oil film in waste circuit boards, achieves the effect of low cost and simple and feasible operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

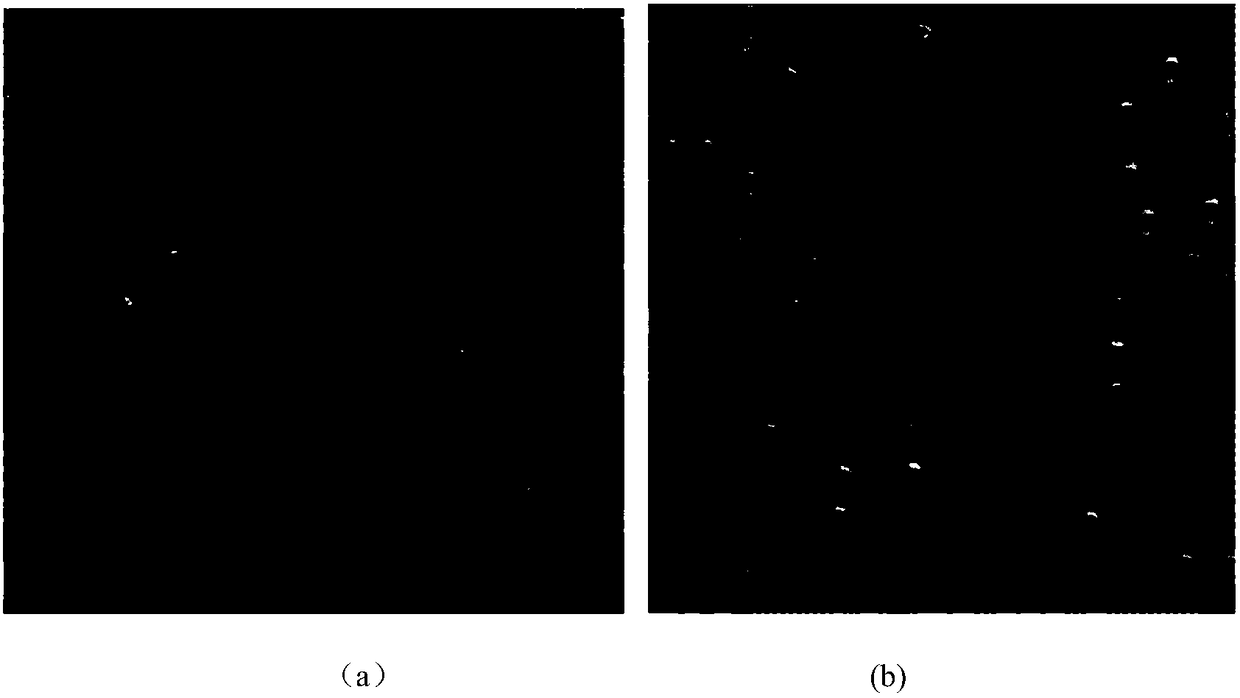

[0018] Select 0.5m 2 The single-layer waste circuit board of the cathode ray tube display is used as the test material, and 1L of NaOH aqueous solution with a mass percentage concentration of 4% is placed in a 2L beaker, heated to 100°C, and the selected waste circuit board is cut into small pieces and soaked in the In the prepared NaOH solution, the soaking time is 14min, then take it out and rinse it with clean water.

[0019] The test result is that the green oil film on all circuit boards is completely removed, and the copper foil layer is exposed, such as figure 1 As shown, a is before removal, and b is after removal.

Embodiment 2

[0021] Select 0.5m 2 The single-layer waste circuit board of cathode ray tube display is used as the test material, and 1L of KOH aqueous solution with a mass percent concentration of 4% is placed in a 2L beaker, heated to 100°C, and the selected waste circuit board is cut into small pieces and soaked in the In the prepared KOH solution, soak for 14 minutes, then take it out and rinse with clean water.

[0022] The test result is that the green oil film on all circuit boards is completely removed, and the copper foil layer is exposed.

Embodiment 3

[0024] Select 0.5m 2 The single-layer waste circuit board of the cathode ray tube display is used as the test material, and 1L of LiOH aqueous solution with a mass percent concentration of 4% is placed in a 2L beaker, heated to 100°C, and the selected waste circuit board is cut into small pieces and soaked in the In the prepared LiOH solution, the soaking time is 14min, then take it out and rinse it with clean water.

[0025] The test result is that the green oil film on all circuit boards is completely removed, and the copper foil layer is exposed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com