Vacuum oil purifier waste water tank

A technology of vacuum oil purifier and waste water tank, which is applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of time-consuming, waste, artificial drainage, etc., and achieve the effect of eliminating labor, convenient cleaning, and ensuring work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

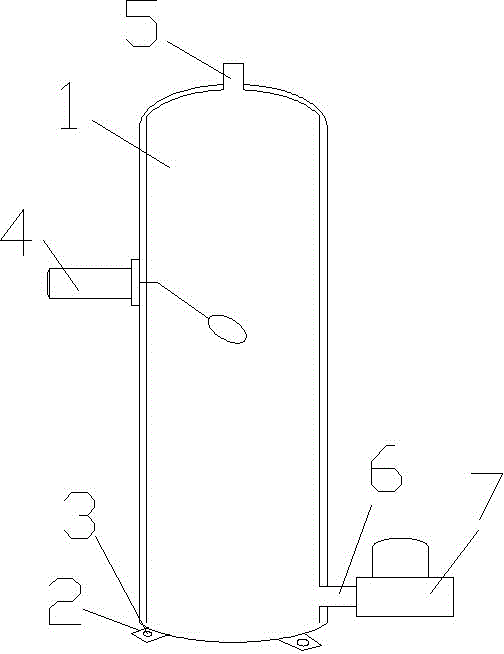

[0011] A waste water tank for a vacuum oil purifier comprises a waste water tank 1, the waste water tank 1 is cylindrical, the edge of the cylindrical bottom surface of the waste water tank 1 is provided with fixing ears 2, and the fixing ears are provided with screw holes 3, The waste water tank 1 is provided with a liquid level controller 4 , the upper end of the waste water tank 1 is provided with a water inlet 5 , the lower end of the waste water tank 1 is provided with a water outlet 6 , and the water outlet 6 is provided with a solenoid valve 7 .

[0012] The liquid level controller is a floating ball liquid level controller, and the model is FUK-150.

[0013] The number of the fixed ears is 2-4, and the number of the fixed ears is preferably 4.

[0014] The waste water tank of the present invention is fixed on the workbench of the vacuum oil purifier with screws and nuts through the fixing ears, and the fixing and disassembly procedures of the waste water tank are conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com