Device and construction method for alternatively jacking hyperbolical closed type steel grid structure step by step

A technology of grid structure and jacking device, which is applied in the direction of building structure and building, can solve the problems that fixed jacking device cannot move radially and cannot lift vertical hyperbolic closed steel grid structure, etc. Synchronization and convenience, easy connection and disassembly, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

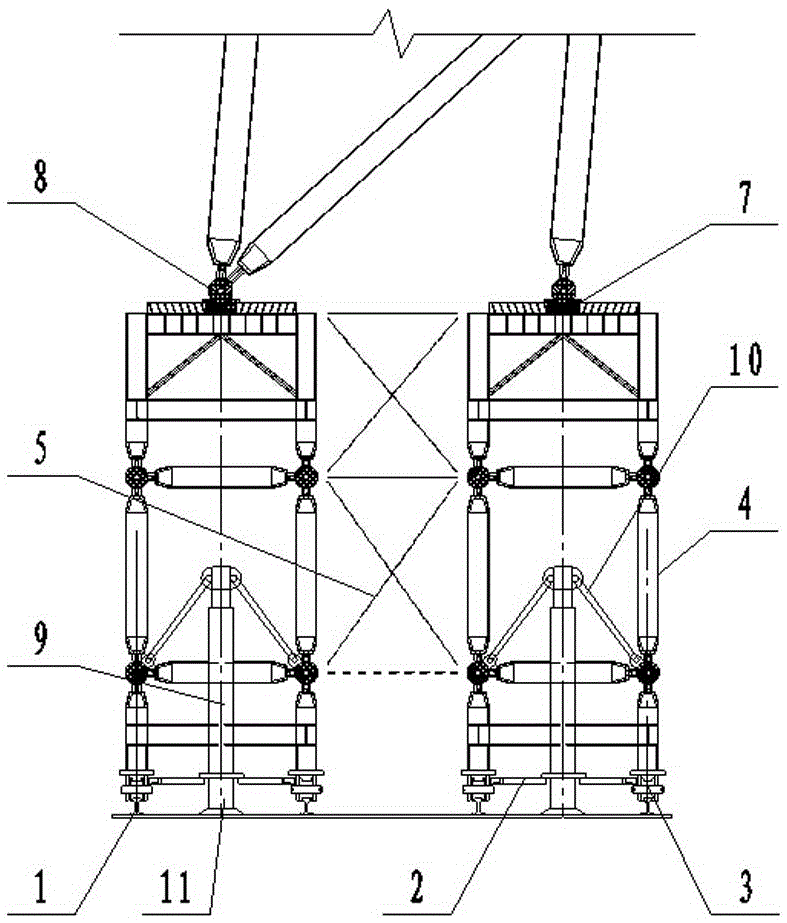

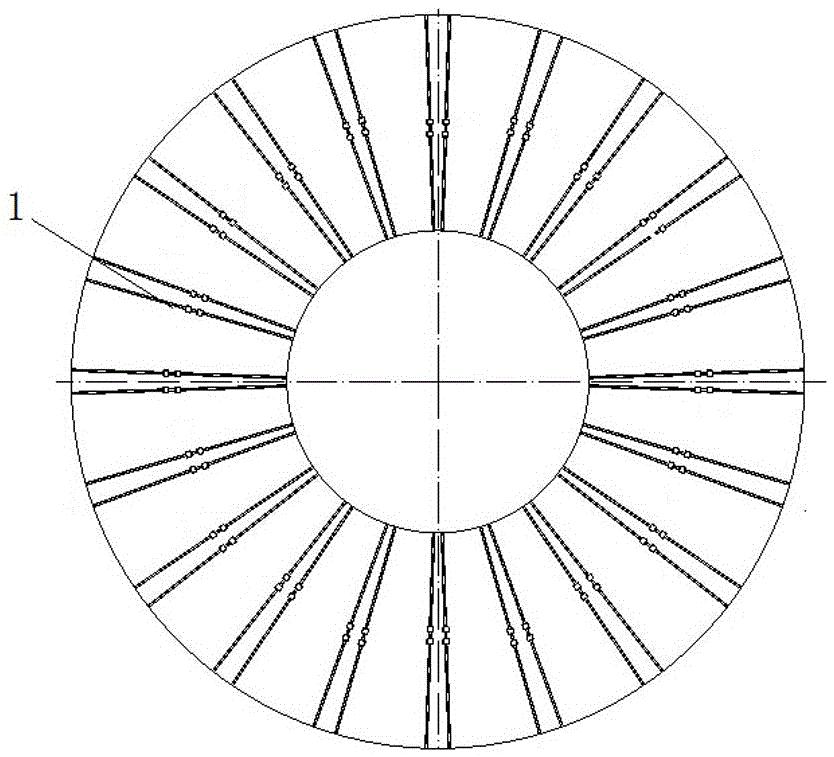

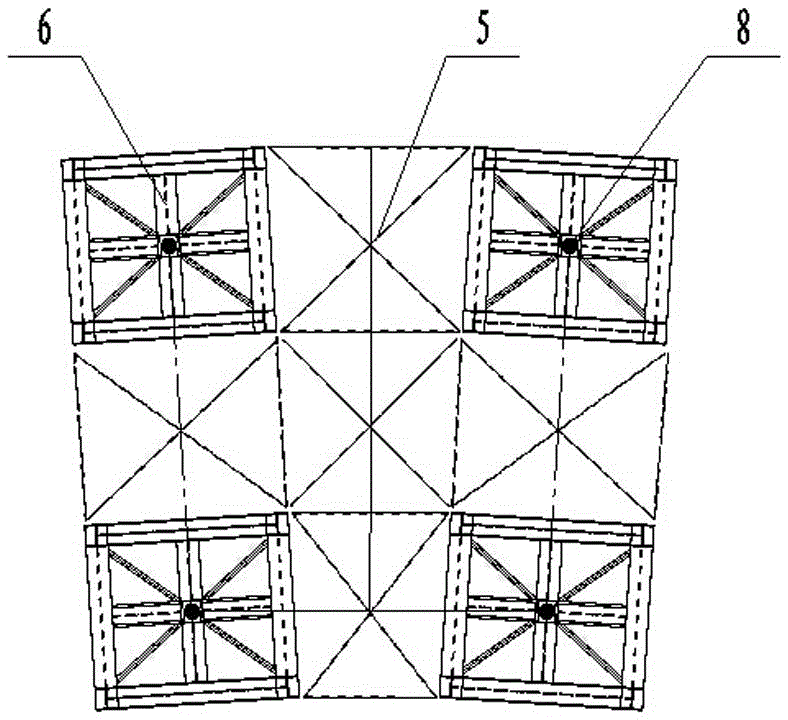

[0036]The hyperbolic closed steel grid structure alternate step-by-step jacking device includes a number of slide rails 1 arranged in the radial direction, and a mobile jack is arranged above the slide rail 1. The mobile jack includes a cross platform 2, a cross platform 2 is provided with rollers 3 sliding on the sliding track 1, and the four corners of the cross platform 2 are provided with vertical support legs 4 connected by several standard joints, and the adjacent vertical support legs 4 Support rods 5 are connected between them, and the top of the vertical support legs 4 is provided with a load-bearing platform, and the load-bearing platform is provided with a position-adjusting channel steel track 6, and a jacking support block 7 is placed in the position-adjusting channel steel track 6, and the jacking support block The upper surface of 7 is provided with a spherical groove matching with the ball joint 8; the cross platform 2 is provided with a hydraulic jack 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com