Inward rotating type grating chain wheel side edge sealing part

A side-sealing, internal-turning technology, which is applied to engine sealing, engine components, water/sludge/sewage treatment, etc., can solve the problems of not paying attention to the sealing of grille plates, increasing operating costs, and affecting filtration effects, etc. Achieve the effect of simple structure, lower operating cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

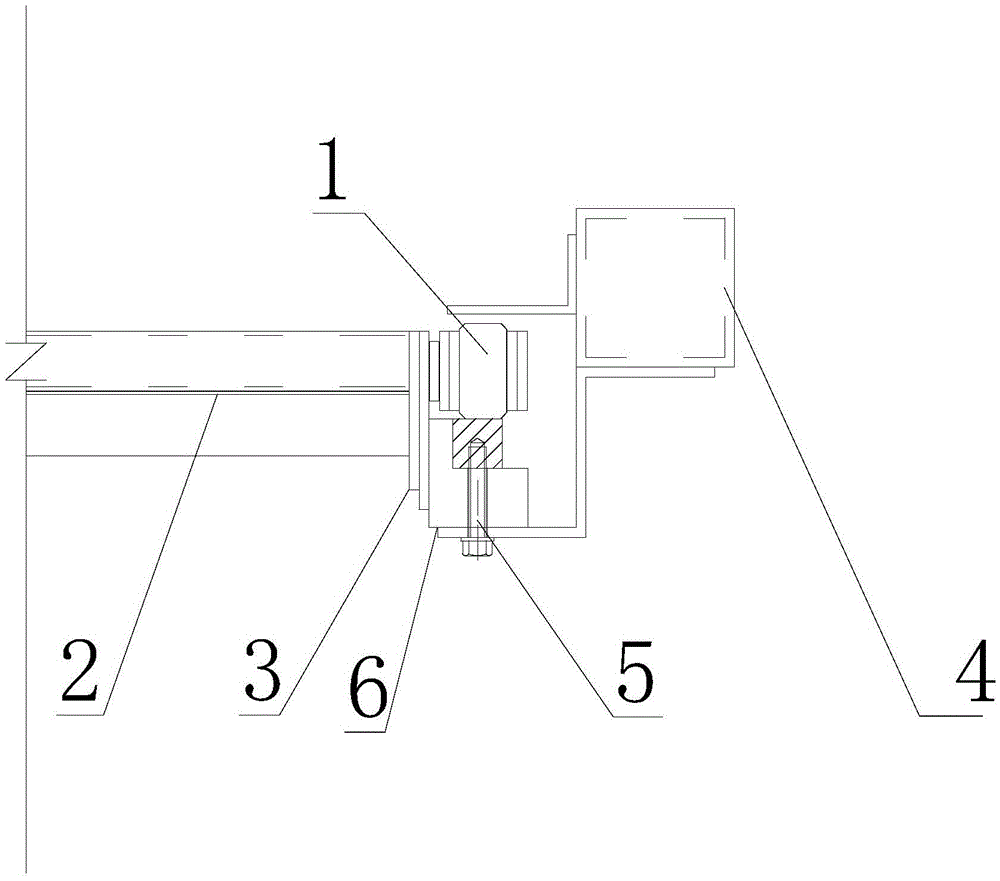

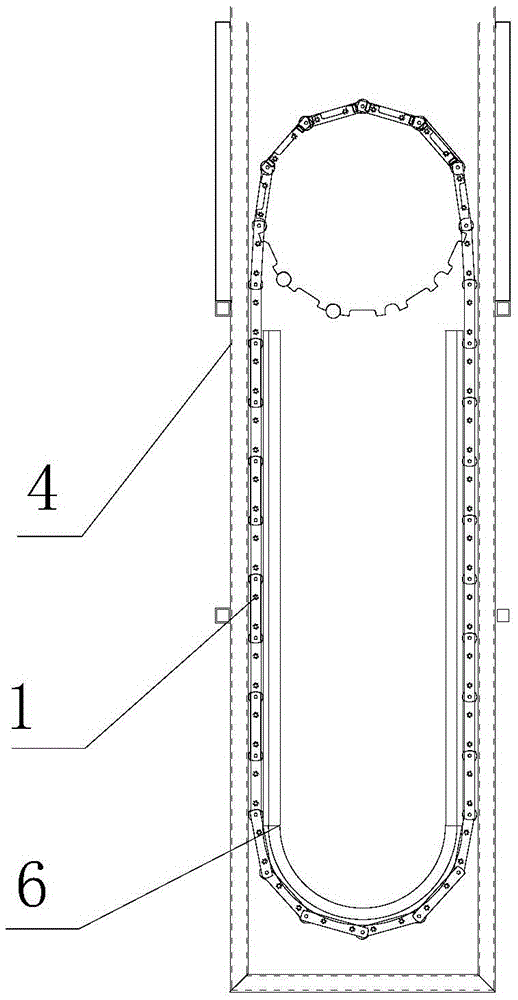

[0012] The present invention will be further explained below in conjunction with the accompanying drawings.

[0013] The invention discloses a side seal of an internally rotating grille sprocket, which comprises a pair of chains 1 and a set of grille plates 2 arranged in the chains 1; the grille plates 2 are fixed on the inner side of the chain 1 through a connecting plate 3 The outer cover of the chain 1 is provided with a fixed frame 4, a circle of displaceable adjustable fixed frame 5 is arranged on the outside of the fixed frame 4, and a ring of polymer seals 6 is arranged on the inner side of the adjusted fixed frame 5, and the polymer seal 6 is close to the connecting plate 3 .

[0014] Wherein, the adjusting and fixing frame 5 can be displaced horizontally.

[0015] Wherein, the polymer seal 6 is a nylon seal.

[0016] Wherein, the chain 1, the adjusting and fixing frame 5 and the polymer seal 6 are coaxial.

[0017] When the equipment is in use, adjust the fixing fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com