A multi-degree-of-freedom drill pipe lubricating swinging rod

A swing rod and degree of freedom technology, applied in the direction of lubricating parts, engine lubrication, engine components, etc., can solve problems such as breakage, uneven lubrication, deformation, etc., and achieve the effect of saving production costs, not easy to wear, and evenly applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing this patent is described further.

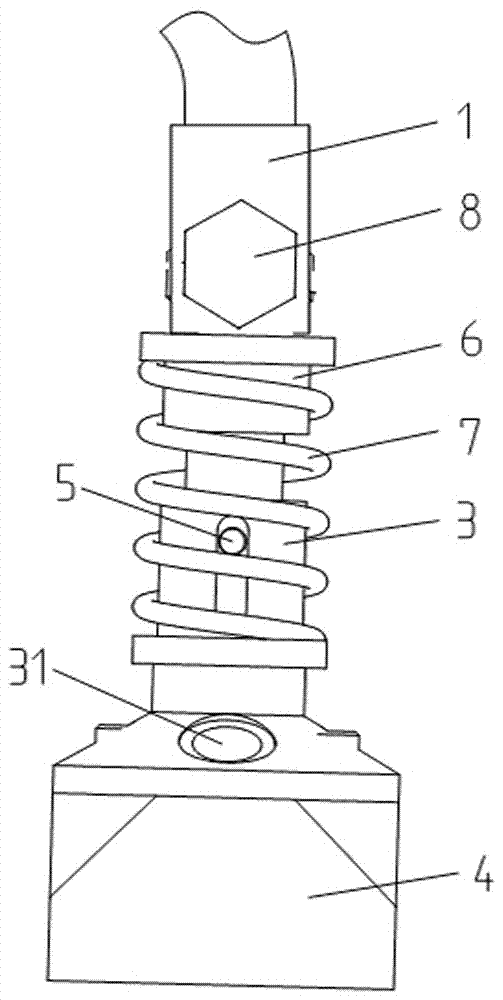

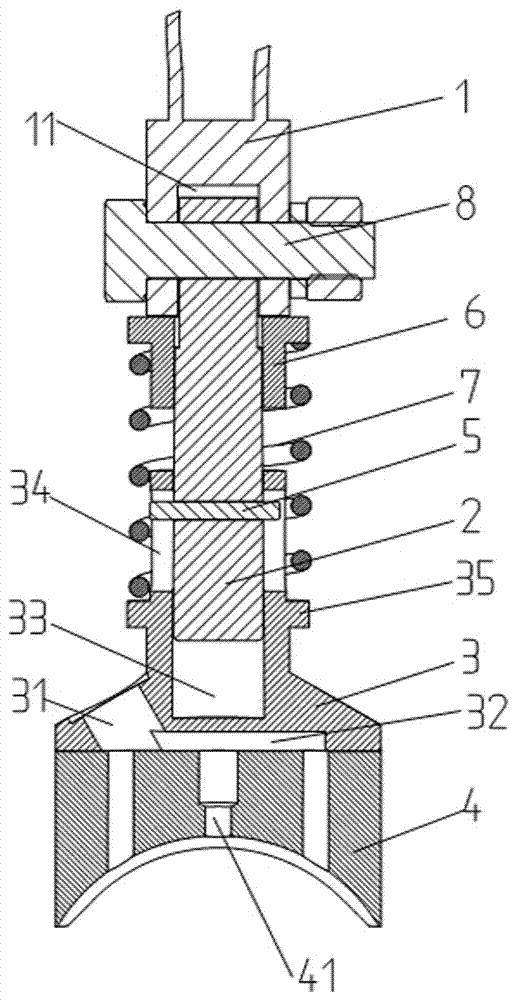

[0013] Such as figure 1 and figure 2 The shown multi-degree-of-freedom drill pipe lubricating swing rod includes a support tube 1, a rotating shaft 2, a nozzle socket 3 and a nozzle 4. The nozzle 4 is made of a wear-resistant material, and the front end of the nozzle 4 In order to fit the curved surface of the drill pipe surface, the oil nozzle 4 is provided with a number of oil injection holes 41 evenly distributed in the width and height directions of the oil nozzle 4. The fuel injection hole A, the fuel injection hole B and the fuel injection hole C located on the left and right sides of the fuel injection hole A, the fuel injection hole B, the fuel injection hole A and the fuel injection hole C are evenly distributed in the width direction of the oil nozzle 4 . The oil nozzle 4 is detachably installed on the front end of the oil nozzle socket 3 through bolts. Compared with the exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com