Passive unbalance treatment module structure

A modular structure, balanced technology, applied in the direction of reducing the asymmetry of the polyphase network, eliminating/reducing the asymmetry of the polyphase network, the board/panel/desk of the substation/switchgear, etc., can solve the three-phase current in the power system. Balance, short service life of electronic components, insufficient IGBT stability, etc., to achieve the effect of less installation process, low manufacturing cost, quick and convenient after-sales and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

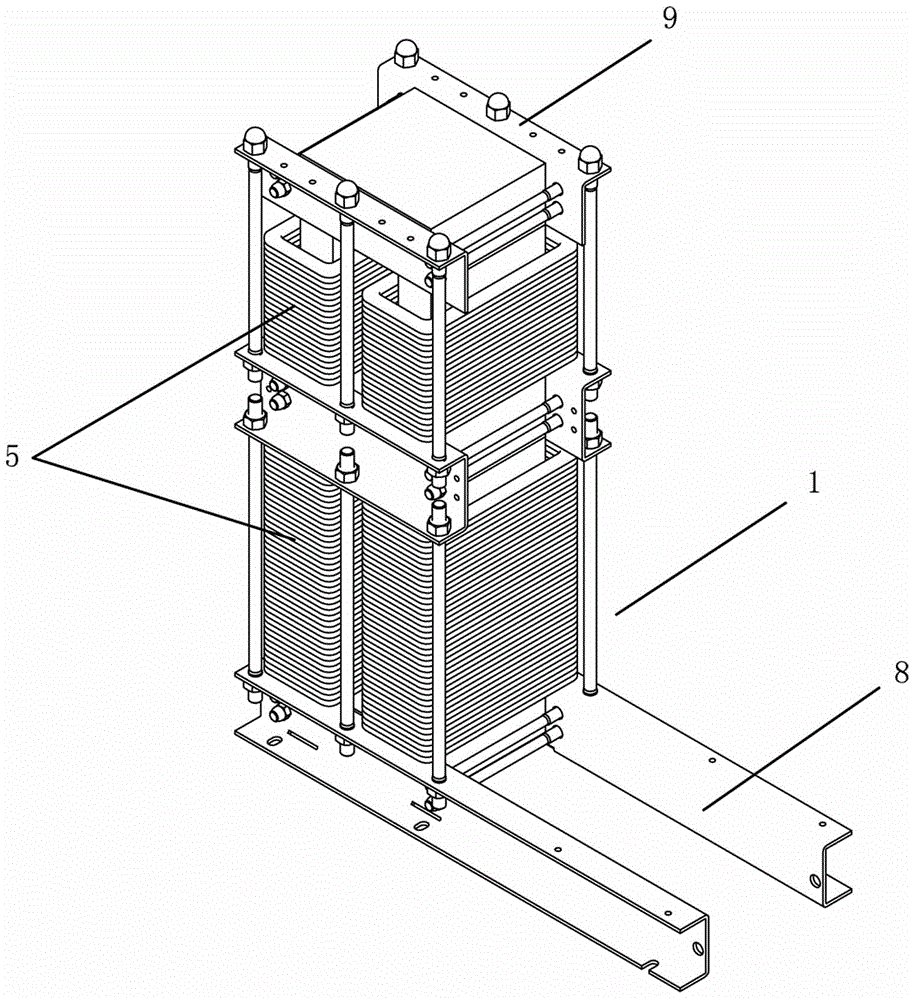

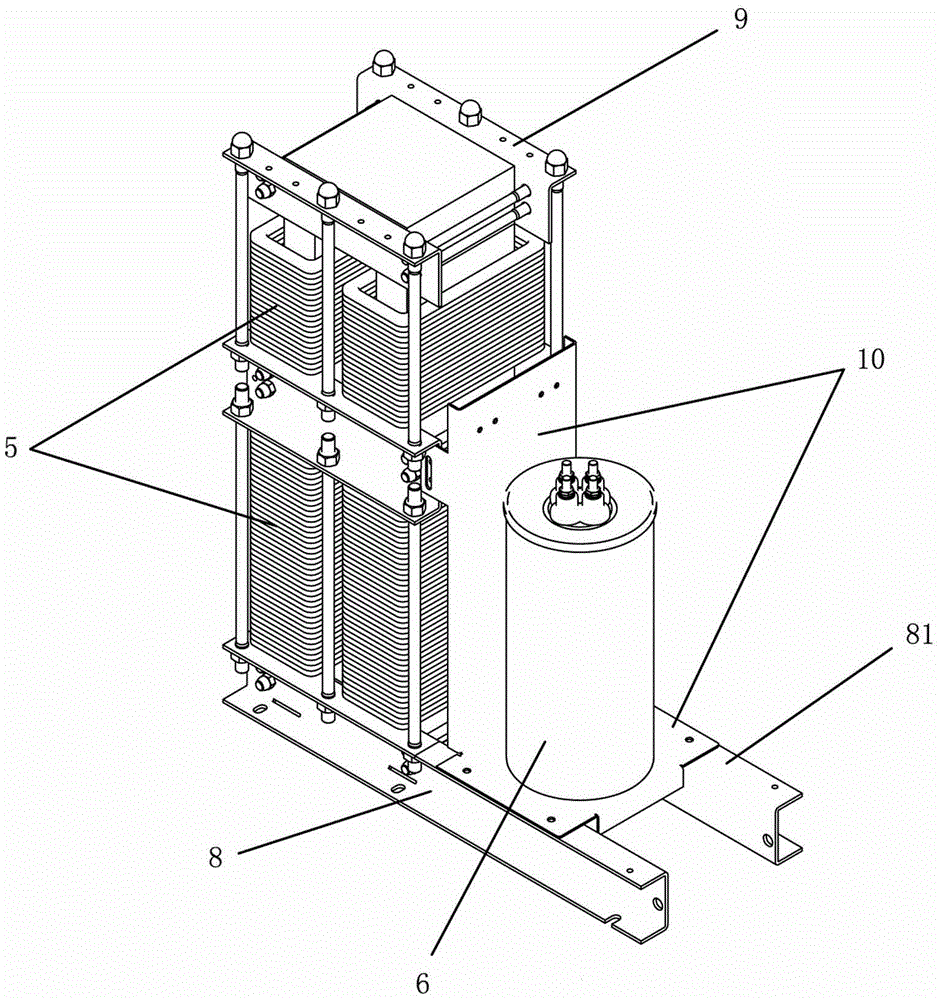

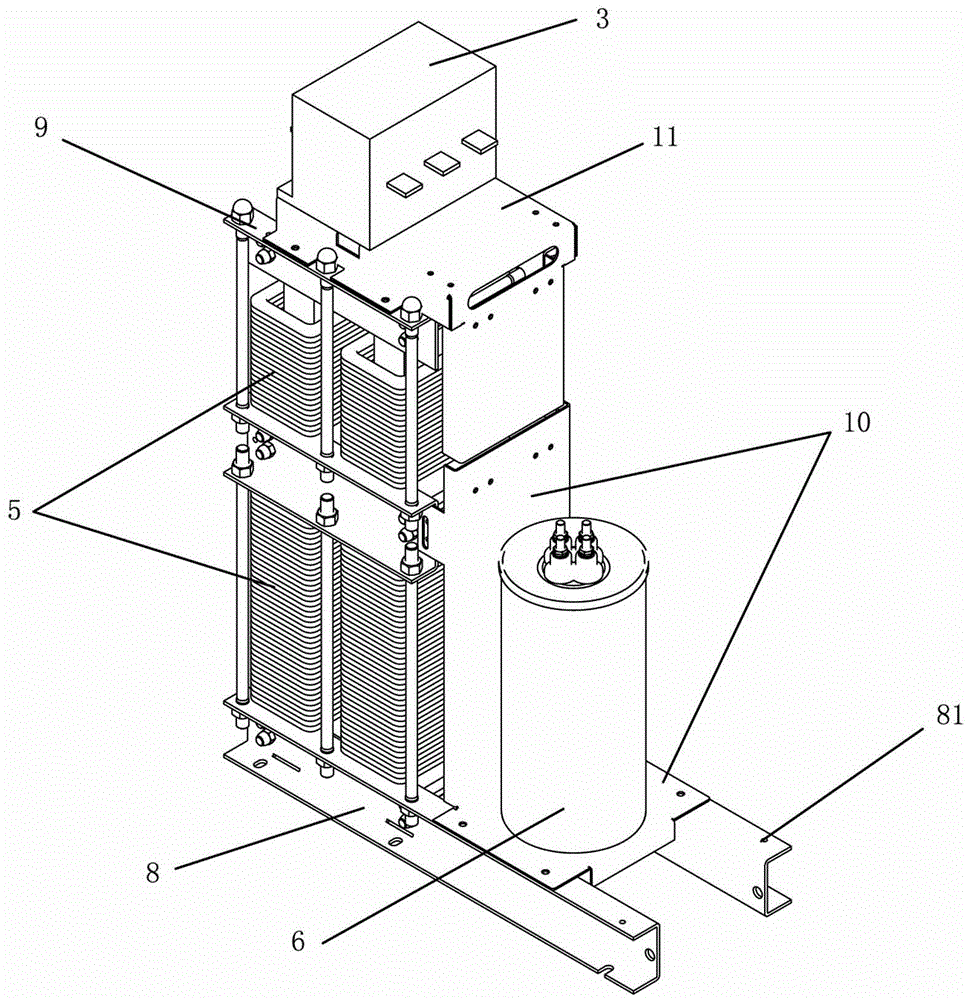

[0035] see Figure 1 to Figure 6 As shown, the structure of the passive unbalance control module includes a mounting frame 1, a knife fuse switch 2, a vacuum contactor 3, a control board 4, a reactor 5, a capacitor 6 and a connecting terminal 7, wherein the mounting frame includes Fixed steel channel 8 and angle steel 9, the fixed steel channel 8 is on the bottom, the angle steel 9 is on the top, the capacitor 6 and the reactor 5 are installed on the fixed channel steel 8 together, the knife melting switch 2, the vacuum contactor 3, and the control board 4 are all Installed on the angle steel, the knife melting switch 2, the vacuum contactor 3, the control board 4, the reactor 5, the capacitor 6 and the connecting terminal 7 are connected in series.

[0036] See figure 1 As shown, as a part of the patented passive unbalance control module structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com