Buried cable laying device

A cable laying and vehicle frame technology, which is applied in the field of direct buried cable laying devices, can solve the problems of low construction efficiency, large human resource occupation, and heavy workload of construction personnel, and achieve the effect of reducing workload and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

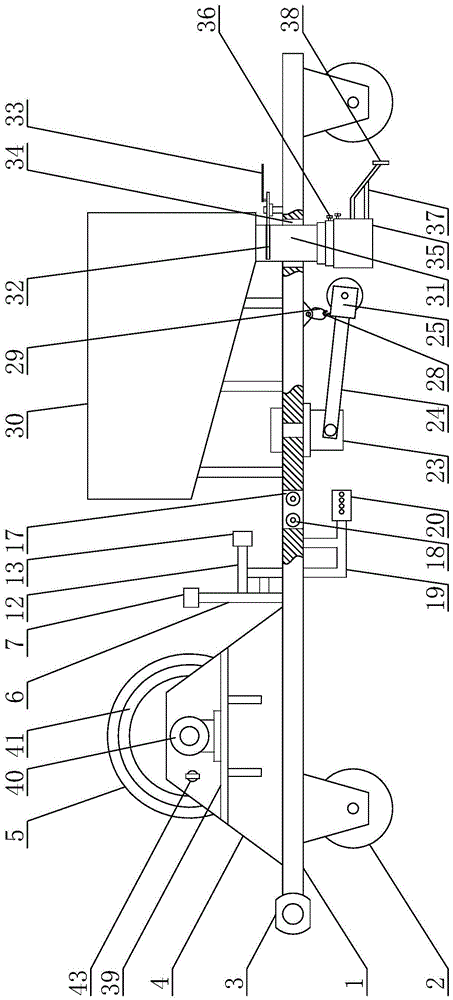

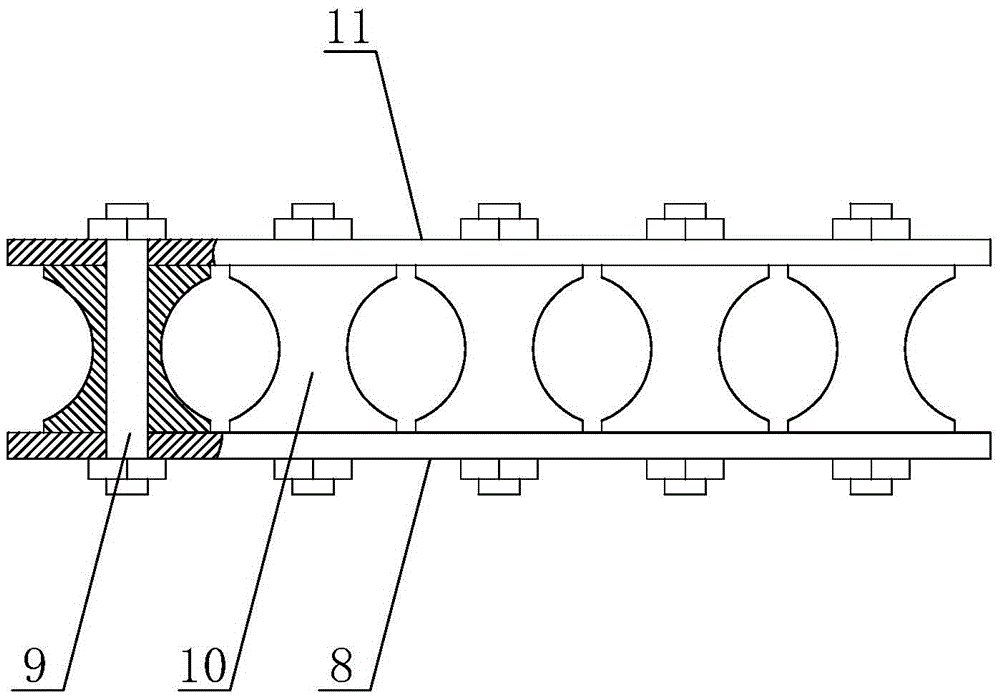

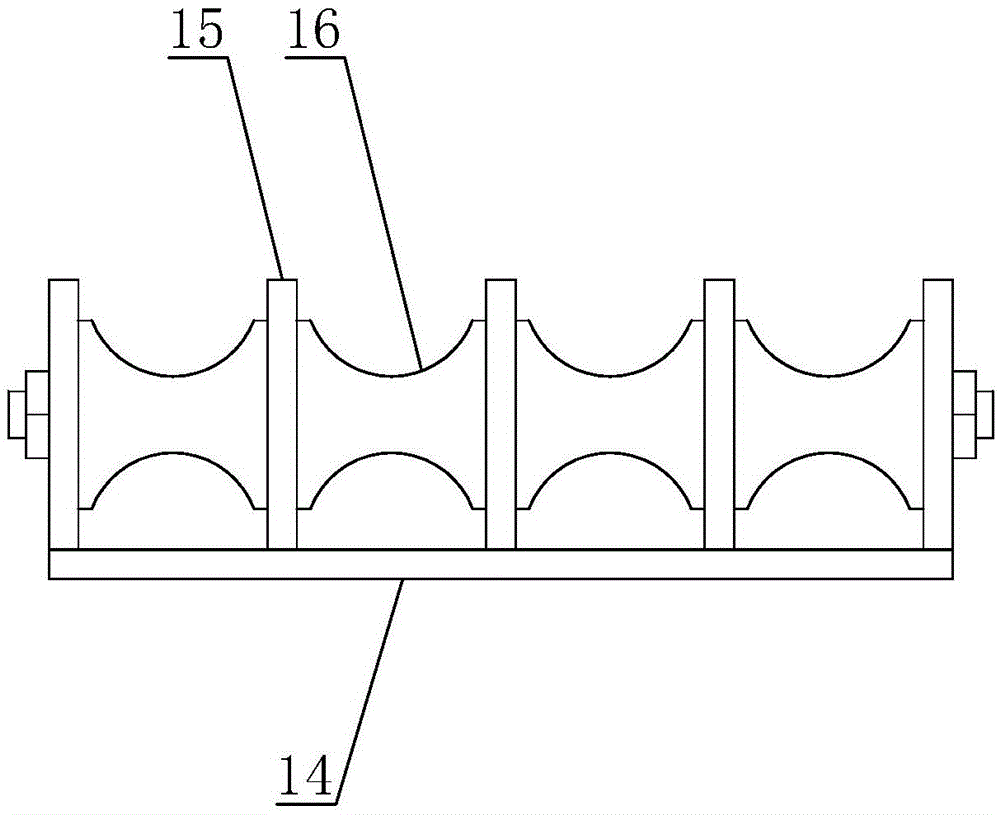

[0034] Embodiment: The present invention is a direct-buried cable laying device, including a vehicle frame, four anti-skid wheels are installed on the bottom of the vehicle frame, and the end of the vehicle frame is welded with a traction hook, which can facilitate the connection between the vehicle frame and Tractor connection. A pay-off rack is arranged on the vehicle frame, and the pay-off rack is welded on the vehicle frame, and four reels are installed on the pay-off rack. The reel locking pin is arranged on the pay-off rack, which can lock the reel during the transfer process of the vehicle frame, prevent the cables on the reel from falling off, and facilitate transportation. A third support plate is arranged on the pay-off frame, and a motor is arranged on the third support plate, and the motor is connected to the wire reel by transmission, and the motor can drive the wire reel to rotate, which can reduce the tension on the cable during the cable laying process, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com