A rail anchor point and a backing plate for that rail anchor point

一种固定点、轨道的技术,应用在固定轨条、轨道、道路等方向,能够解决制造技术方面昂贵等问题,达到优化可简易安装、尺寸小、重量轻的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

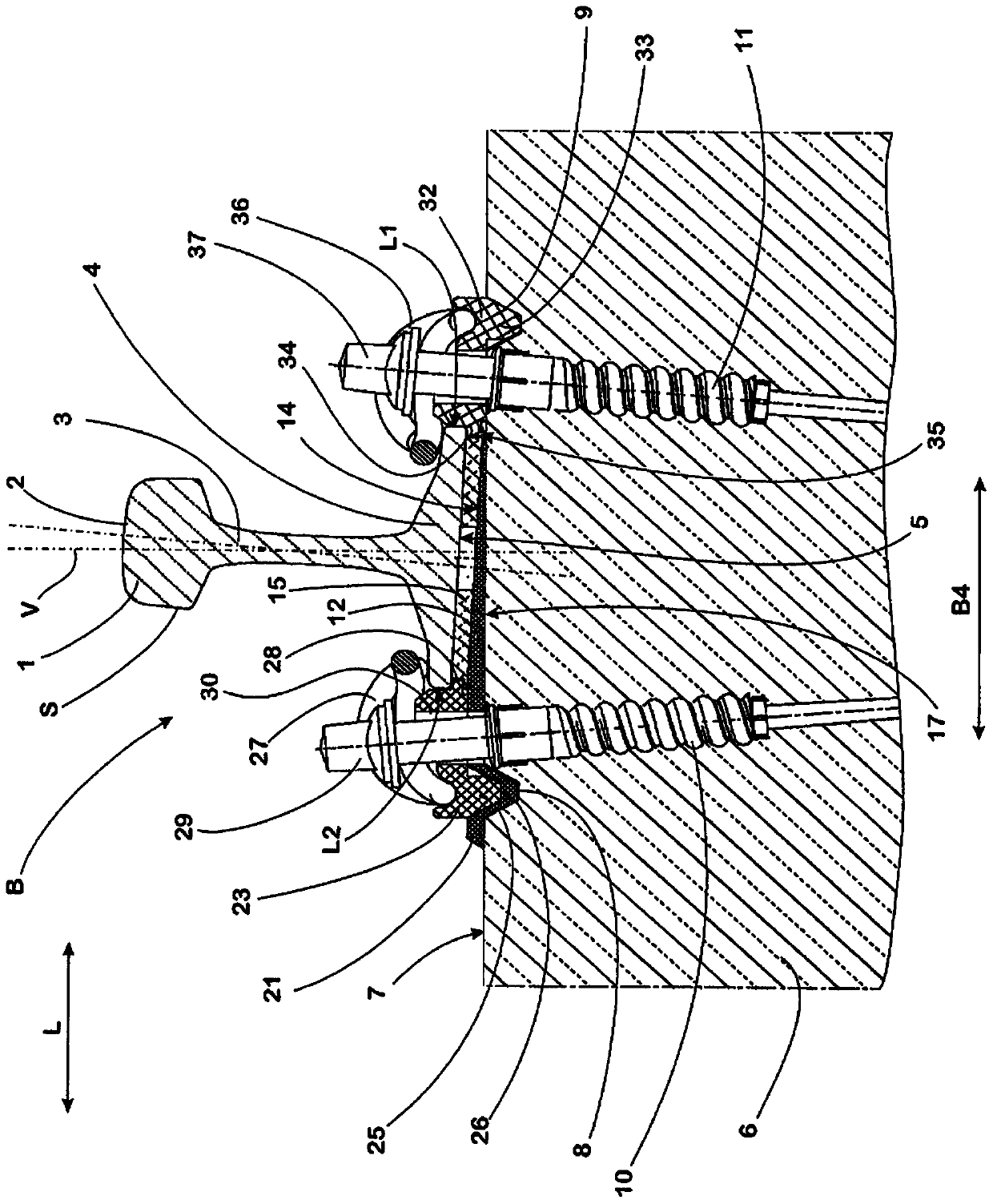

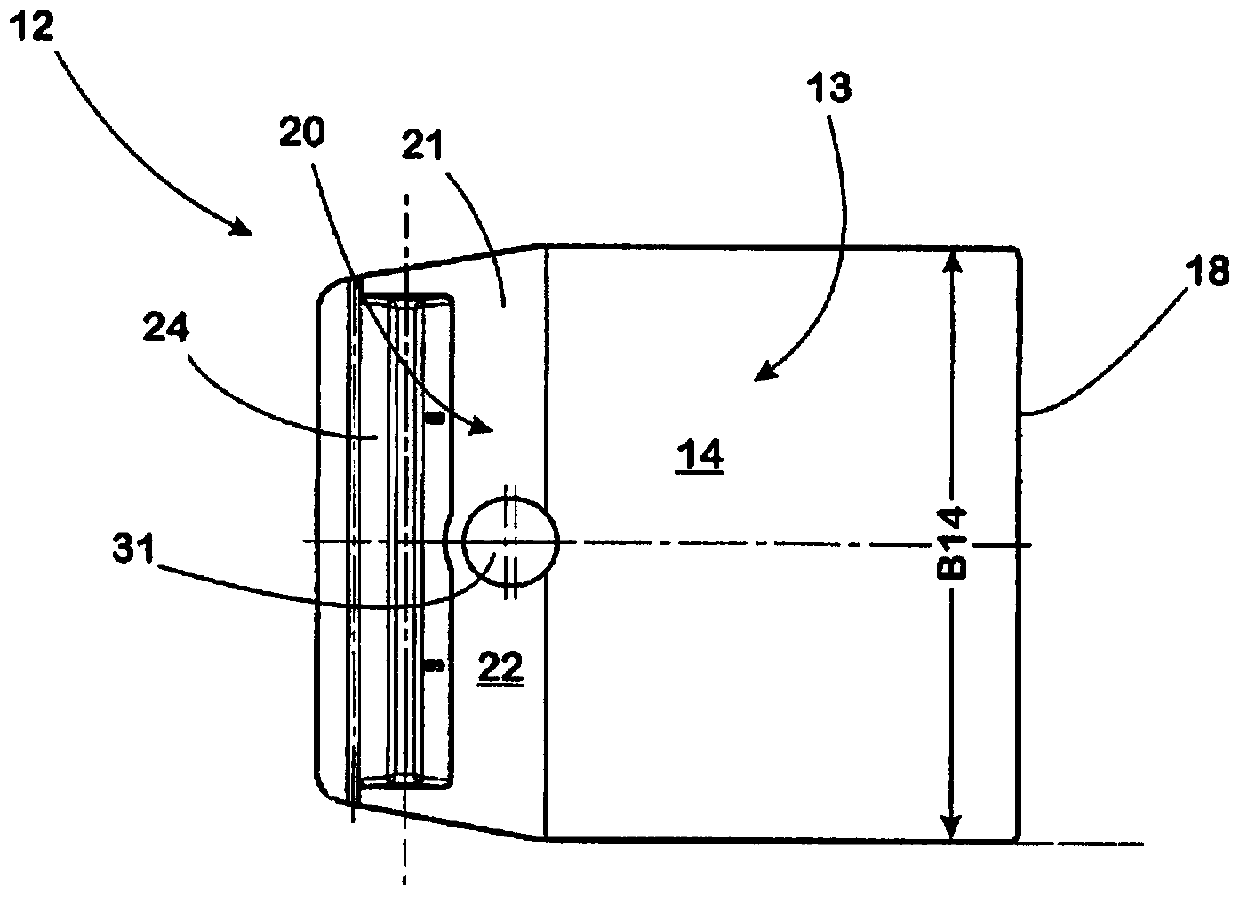

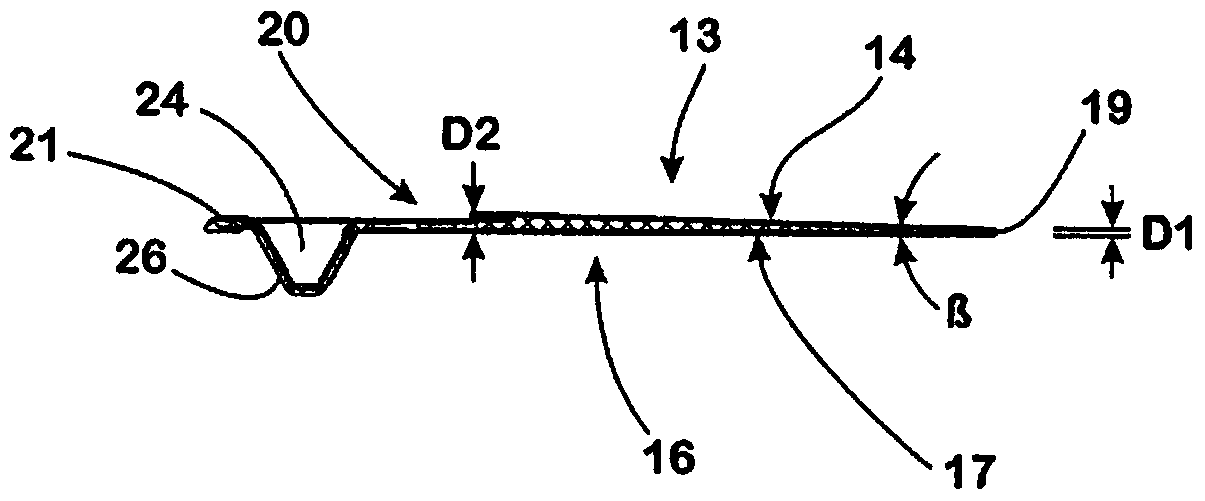

[0041] Track S is fixed on the attached figure 1 At the track fixing point B shown in, it usually has: a rail head 1, on the upper side of which is formed a running surface 2 for a rail wheel (also not shown) of a rail vehicle (not shown); The rail web 3 supporting the rail head 1; and the rail bottom 4, which is arranged in the center of the rail bottom. The rail bottom 4 is wider than the rail head 1 and has a flat supporting surface 5 on its underside.

[0042] The track fixing point B includes a foundation 6, which in this embodiment is formed by a common type of sleeper cast by concrete. The foundation 6 has a flat contact surface 7 on its upper side, which extends with the length of the foundation 6 measured transversely to the longitudinal direction L of the foundation aligned with the track S.

[0043] Two groove-shaped grooves 8 and 9 are formed on the contact surface 7 at intervals, and the two grooves extend parallel to each other and parallel to the longitudinal extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com