Sowing and plastic film mulching machine

A technology of seeding wheel and frame, which is applied to plant protection covers, botany equipment and methods, gardening, etc., and can solve the problem that plastic film is difficult to achieve a good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

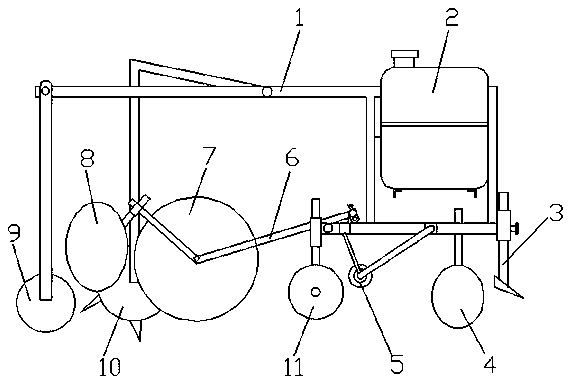

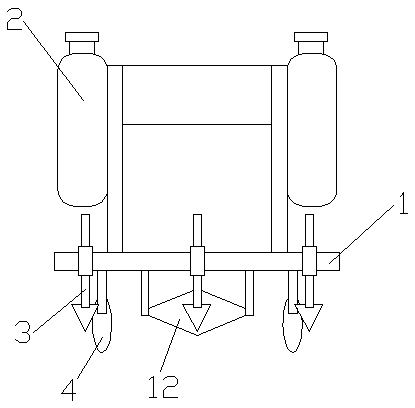

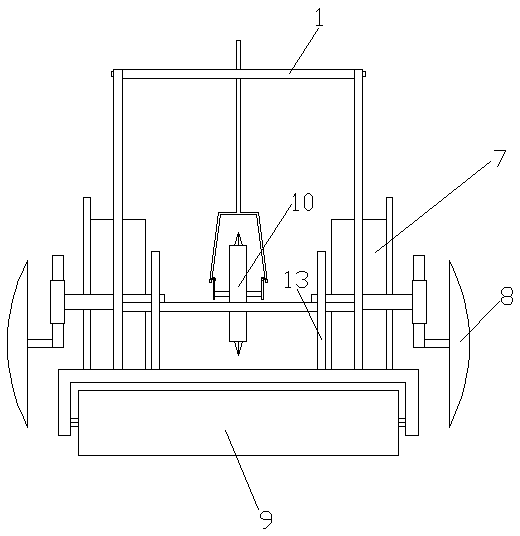

[0023] Such as figure 1 , 2 As shown in , 3, a seed spreading machine includes a frame 1, a medicine box 2 is provided on the upper side of the front part of the frame 1, a spraying port is provided at the bottom of the medicine box 2, and a film roller 5 is provided on the lower side of the frame 1 , the rear of the mulching roller 5 is provided with left and right two rows of sowing wheels 7 fixed on the frame, and several sowing duckbills are evenly arranged on the sowing wheels 7, and the rears of the left and right two rows of sowing wheels 7 are fixed on the frame. The left and right cover soil plates 8, the bottom of the frame 1 front side are provided with a ground shovel 3, and the rear of the ground shovel 3 is provided with a trench wheel 12. The trench wheel 12 is a roller with an olive-shaped structure with a wide middle width and narrow ends. The trench wheel 12 is about Both sides are symmetrically provided with ditching disc 4, and frame 1 rear side middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com