Ultrasonic transducer control method and control system

An ultrasonic transducer and control method technology, applied in ultrasonic/sonic/infrasonic equipment control, ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, etc. The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, the embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0053] During the working process of the transducer, the electrical signal emitted by the ultrasonic transducer array element is converted into an acoustic signal. During this process, corresponding heat energy is generated, and the heat energy is further diffused to the surface of the transducer through the matching layer and the lens. .

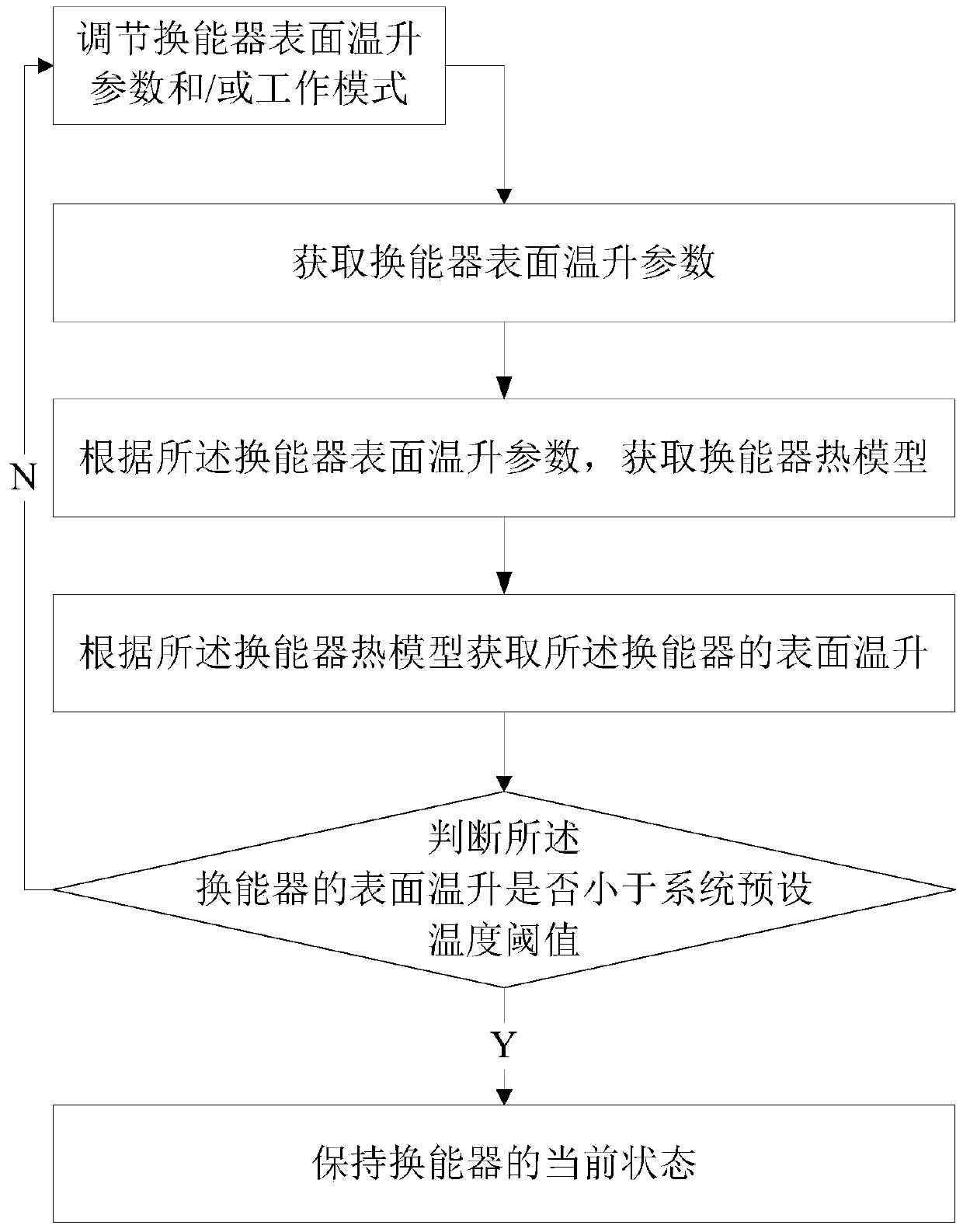

[0054] Such as figure 1 as shown, figure 1 An ultrasonic transducer control method provided in an embodiment of the present invention, the method includes:

[0055] The surface temperature rise of the transducer is obtained according to the transducer thermal model.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com